4

1. Important notes – Please read this first

Thank you for purchasing the LokProgrammer set 53450/

Thank you for purchasing the LokProgrammer set 53450/

Thank you for purchasing the LokProgrammer set 53450/

Thank you for purchasing the LokProgrammer set 53450/

Thank you for purchasing the LokProgrammer set 53450/

53451.

53451.

53451.

53451.

53451. With the LokProgrammer you can program ESU LokPilot-

and LokSound decoders.

The LokProgrammer 53450 consists of two elements: An

interface module that serves as the physical connection

between the PC and the locomotive, and the software that

can be run on any PC using MS Windows. The set 53451 has

an additional USB adapter but is otherwise the same as 53450.

Never was it easier to program a digital decoder than with

LokProgrammer. Thanks to the graphic interface of MS

Windows you can achieve the optimal adaptation of LokSound

decoders even if you have very little or no experience in

programming digital decoders. This combination allows you to

easily manipulate and adjust the many features and properties

of LokSound decoders with your PC.

LokProgrammer also allows you to modify all sound fragments

and sound effects stored on the decoder as often as you desire.

ESU provides over 100 different sound files on the ESU web

site at www.esu.eu. You will certainly find the right sound for

your locomotive.

Please also take note of the license agreement regarding

downloading and using the sound files contained in the appendix.

This manual describes in detail how to modify sounds and which

methods to use to achieve the desired results.

We wish you lots of fun in the world of LokSound.

ESU electronic solutions ulm GmbH & Co KG, March 2009

2. Installation and start-up of the LokProgrammer

Please note the remarks regarding installation to assure that

your LokProgrammer software keeps working to your full

satisfaction!

2.1.

2.1.

2.1.

2.1.

2.1. System requirements

System requirements

System requirements

System requirements

System requirements

In order to use this software you need a commercially available

PC with the following requirements:

• Operating system: Microsoft Windows 98, 2000 or XP, alsoVista

as from version 2.6.3; but not Windows NT

• CD-ROM drive

• One serial port or an USB interface on your PC

• Audio card

• 10MB minimum available memory on your hard disc

For the utilization of the sound files with this software an Audio

Card must be installed. All cards with a Windows driver are

suitable.

Installation and start of the LokProgrammer

2.2. Connecting the LokProgrammer

2.2. Connecting the LokProgrammer

2.2. Connecting the LokProgrammer

2.2. Connecting the LokProgrammer

2.2. Connecting the LokProgrammer

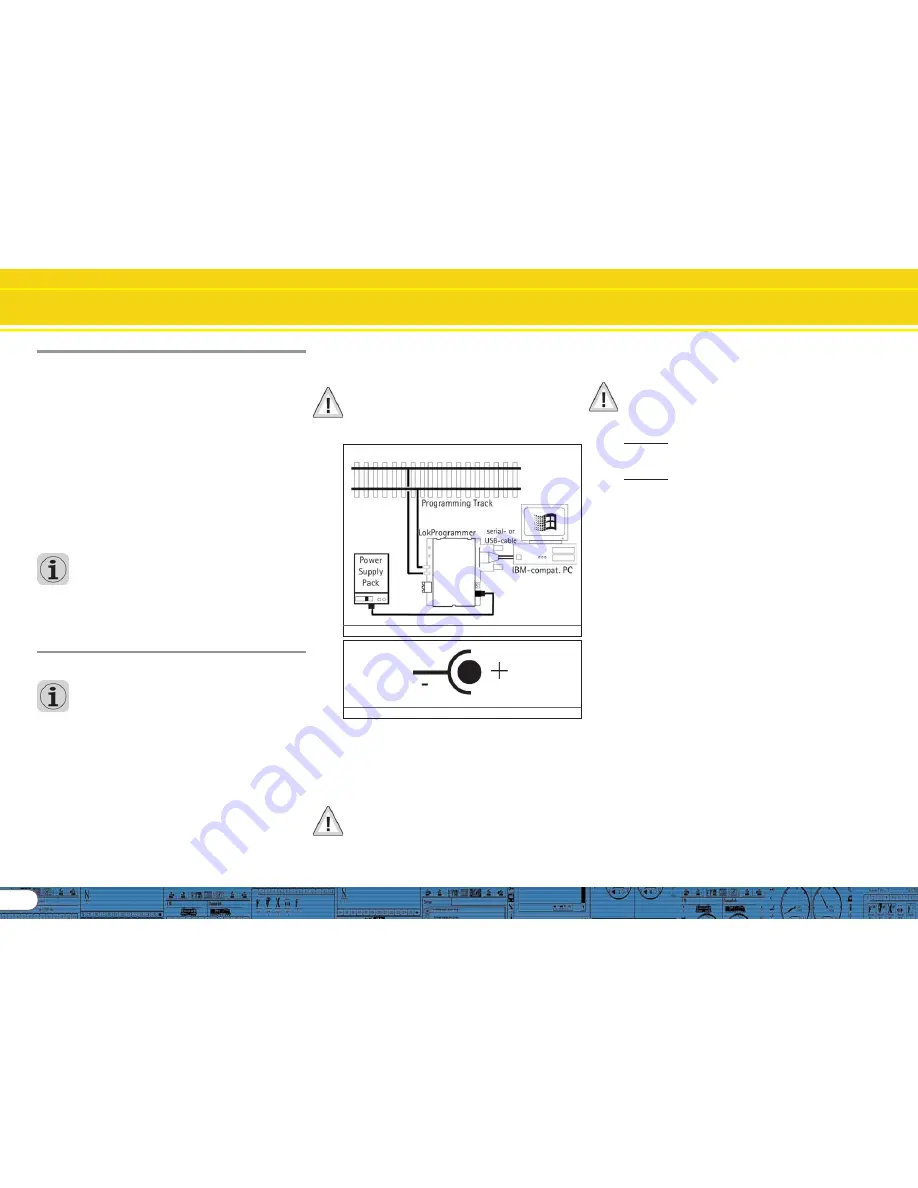

The LokProgrammer has to be connected as shown in Figure 1:

Use the serial cable respectively the USB-adapter cable provided

to connect the LokProgrammer to any available COM port (or

USB-port) of your PC. Which port you select is immaterial.

Please make sure that the programming track is completely

isolated from the rest of the layout to avoid possible damage of

your LokProgrammer hardware!

Also make sure that there are no electrical connections

between the individual wires.

Fig.2.: Polarity of Power Supply Connector

There are two options for the power supply:

• Use the power pack with mains plug provided with the

LokProgrammer. Connect the output of the power pack to

the power supply terminals of the LokProgrammer as per Figure

2.

• Use the AC power output of a model train transformer and

wire it to the screw terminals. We recommend this option for

programming gauge 1 locomotives

Never connect both terminals at the same time. This could

destroy the LokProgrammer!

After connecting the power supply the green LED on the

LokProgrammer should light up.

The terminals „Track Out“ on the LokProgrammer are to be

wired to the programming track. Polarity is irrelevant.

Make sure that the programming track is fully isolated from

the layout!

The two LEDs on the LokProgrammer indicate the following:

Green LED:

• Is lit continuously when supply voltage is available.

• Blinks when the LokProgrammer receives data from the PC.

Yellow LED:

• Blinks quickly when voltage is applied to the programming

track and data is transferred.

• Blinks slowly if the LokProgrammer detects a high current and

is disconnecting the programming track.

2.3. Installing the software

2.3. Installing the software

2.3. Installing the software

2.3. Installing the software

2.3. Installing the software

Make sure that the LokProgrammer is connected as described

above and is ready for use.

As soon as you insert the CD-ROM into the drive the installation

program is starting automatically.

Should this not be the case select the CD-ROM drive in „Desk

Top“ or in the „Windows Explorer“ and click onto „Set up“.

Alternatively you may click on the START button in the tool bar

and select „Run“. Then type „x:\setup.exe“ and „OK“. Of

course you must enter the name of the CD-ROM drive instead

of the „x“ (usually „D“):

After a short while the program should start. Follow the

instructions on the monitor and wait until the program is installed

on the hard disk.

2.4. Starting the program

2.4. Starting the program

2.4. Starting the program

2.4. Starting the program

2.4. Starting the program

The installation program creates an entry in the start menu.

Select „LokProgrammer vX“ in the Start menu under „Pro-

grams“; „X“ stands for the version number of the software.

Select „LokProgrammer“. Then the program will start.

Fig.1.: Wiring the LokProgrammer

Summary of Contents for LokProgrammer

Page 35: ...35...