28

16.1.6. Mirroring turnouts

In order to draw so called 45º yard ladders it may be necessary

to mirror turnouts. Thus a right hand turnout changes to be a

left hand one. Only right hand and left hand turnouts can be

mirrored.

• Select the screen button “Mirror turnout”.

• Click onto the symbol of the (right hand or left hand) turnout

that you wish to mirror.

16.1.7. Delete symbols

Symbols no longer required or inserted by mistake can be de-

leted at any time.

Only the track and accessory symbols are deleted not the actual

accessories or routes. If you wish to delete an accessory or rou-

te you must do this in the turnout control panel.

• Select the screen button “Delete symbol.

• Click onto the symbol that you wish to delete.

16.1.8. Change the name of the page

While in the configuration mode you may give each page (pa-

nel) its own name.

• Select the panel whose name you want to change.

• Click onto the keyboard symbol and enter the name.

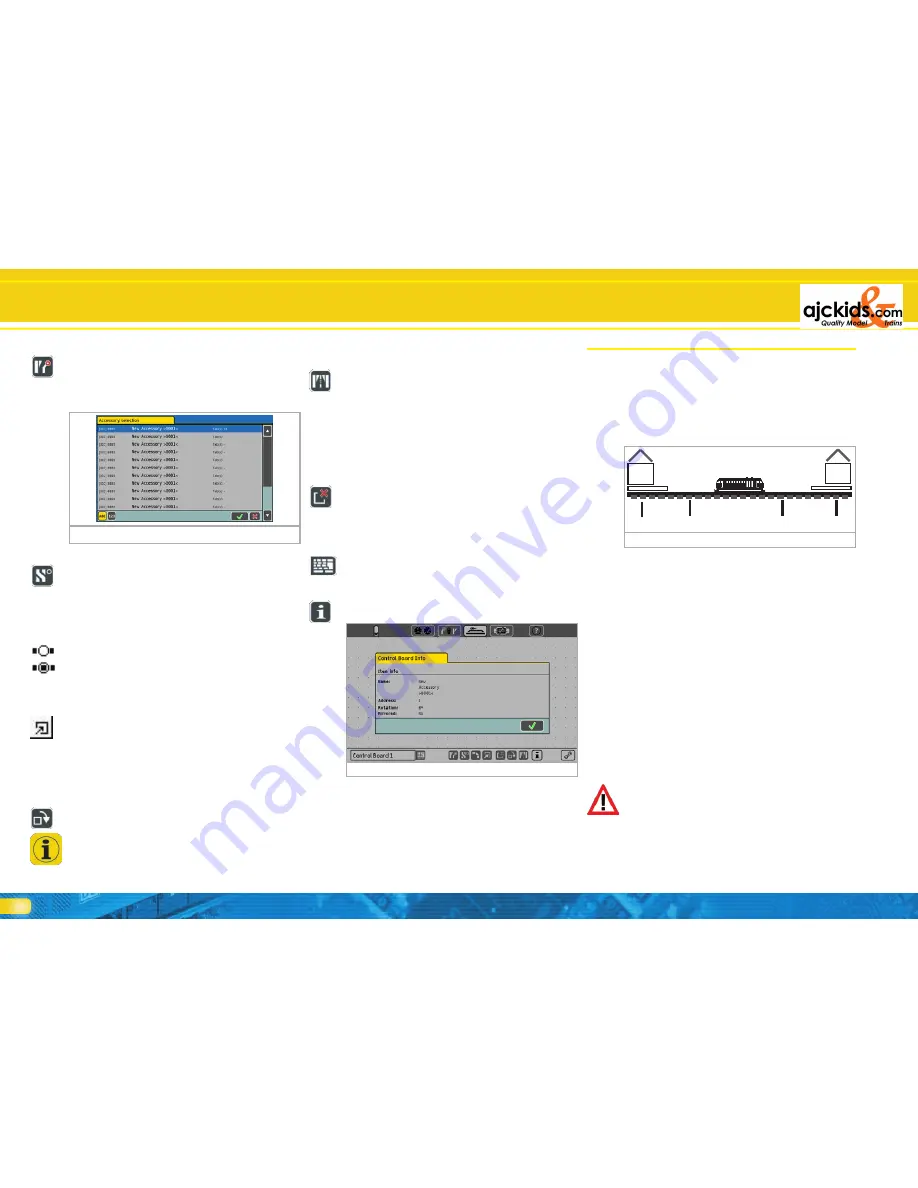

16.1.9. Information regarding accessories / routes

Occasionally one wants to find out which accessories or routes

are hidden behind a certain symbol. This can be done easily.

• Select the screen button “Field info“.

• Click onto the symbol of which you want more info. A window

providing detailed information will open.

Track Diagram Switching Panel & „Shuttle Train” Mode

17. Running trains in „shuttle train” mode

The shuttle train function is quite a useful tool for running loco-

motives automatically between two points (terminal stations).

ECoS differentiates between two terms:

• Shuttle train line: the track section on which the loco should

travel forward and backwards

• Loco in shuttle train mode: loco that is dynamically assigned to

a shuttle train line and travels „out and back”.

A shuttle train line must comprise of the following:

a) Station1

b) Brake point for station1

c) Station 2

d) Brake point for station 2

The train stops at each station for a pre-determined layover

time before it travels back to the other station. The sequence

happens as follows:

• As soon as the train from station 1 reaches the brake point for

station 2, ECoS transmits a „Stop” command (speed step „0”)

to the train. At the same time a timer is started inside ECoS.

• The train slows down with the set deceleration and stops. De-

celeration has to be set in such a way that the train definitely

stops in station 2. You may have to experiment a little.

• Once the pre-set layover time is past (T1), the timer gives the

signal and the train receives a command to change direction.

The train is still stopped in station 2; it is now ready for depar-

ture and the headlights are switched correctly for the return

trip.

• Once the timer signals departure time (T2) the train accelerates

and moves towards station 1. Thus the procedure begins once

again.

• The periods T1 and T2 are of equal duration. The time the train

takes from brake point 1 plus the time the train is stopped

while still set to the original direction is the same as the time

the train waits in the station after having changed the direction

setting.

• These periods are identical for both stations. The distance from

the brake points to the station must be the same in both sta-

tions since the braking distance is subject to the set decelerati-

on of the locomotive.

For detecting the brake points you have to install and assign

two s88-contacts.

Figure 78

a)

c)

b)

d)

Figure 77

• Select the screen button “Insert accessory”.

• Click onto the location in the track diagram where you want to

place the accessory.

• A window showing all accessories will open.

• Select the desired accessory.

16.1.3. Insert a route

• Select the screen button “Insert a route”.

• Click onto the location in the track diagram where you want

to place the route button. A window showing all routes will

open.

• Select the desired route.

You can switch a route in the track diagram at any time. The

currently set route is highlighted.

Route, not set

Route, all accessories set correctly

16.1.4. References to other panels

For easier navigation between different panels you can enter

references on each page. When pressing the reference symbol

that panel will be automatically displayed.

• Select the screen button “Reference to other panels”.

• Click onto the location in the track diagram where you want to

place the reference button. A window showing all panels will

open.

• Select the desired panel.

16.1.5. Turn elements

In order to achieve the desired orientation of a symbol you can

turn them clockwise, even at a later stage.

• Select the screen button “Turn symbol“.

• Click onto the symbol that you wish to turn.

When establishing longer sections of straight track you should

have inserted at least on such symbol. Then you can turn it

to the desired orientation. When you insert the same symbol

subsequently it will automatically appear with the correct ori-

entation.

Figure 76