59

seCtIon 5

MaIntenanCe

eleCtrIC shoCK Can KIll!

open Wall DIsConneCt sWItCh BeFore atteMptIng anY MaInte-

nanCe on:

plasma console

•

plumbing box

•

plasma torch

•

interconnecting cables

•

WarnIng

CautIon

only trained personnel should perform maintenance or repairs on

this equipment.

Frequent inspection and cleaning of the ESP-200 and related equipment are recommended for safety and proper operation.

Consider the following during inspection and cleaning:

Check work cable to workpiece connection.

•

Check safety earth ground at workpiece and at power source chassis.

•

Check heat shield on torch. Replace if damaged.

•

Check torch electrode and cutting nozzle for wear daily.

•

Ensure cable and hoses are not damaged or kinked.

•

Ensure all plugs, fittings, and ground connections are tight.

•

Check screen filter in coolant pump (located inside console) periodically and flush as required.

•

5.2 Inspection and Cleaning

5.1 general

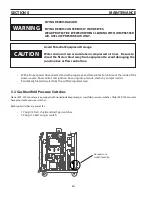

Location of

pump filter

Summary of Contents for ESP-200

Page 1: ...ESP 200 Plasmarc Cutting System Instruction Manual F15 462 C 02 2008 ...

Page 12: ...12 section 2 description ...

Page 31: ...31 section 3 installation Plumbing box fully connected including setup pendant ...

Page 32: ...32 CE 1 2 3 4 5 6 7 9 10 11 12 13 16 19 20 21 22 15 17 18 14 section 3 installation 8 ...

Page 84: ...84 section 7 replacement parts 1 2 3 4 5 6 7 8 9 10 11 12 13 7 6 Right Inside View ...

Page 88: ...88 section 7 replacement parts 6 1 4 5 6 R ef R ef 2 3 7 8 Back and Top Inside View ...

Page 92: ...92 section 7 replacement parts 1 2 3 4 5 6 7 8 7 10 Remote Setup Pendant P N 37145 ...

Page 100: ...100 notes ...