44

4.4.3 process Data for pt19xls (or pt-600) and esp-200

4.4.3.1 Introduction

seCtIon 4

operatIon

The cutting speeds and conditions in the following tables were selected to give the best quality with a particular gas com-

bination at a specific current. They are unique to the ESP-200/PT19XLS combination because of restrictive gas ports built

into the power supply

Consumables - Refer to recommended parts for these conditions. Use of parts in combinations and ap-

•

plications other than as described herein can result in damage to the torch or poor performance.

Gas and Current Selection- Refer to the following tables to chose the most appropriate conditions for

•

your application.

Maximum Economy- Refer to Paragraph D for high speed cutting conditions where cost is a principle

•

concern.

4.4.3.2 process Data at 50 to 65 amps (pt-19xls and pt-600)

Refer to your torch manual for recommended consumables for cutting at this current.

NOTES:

CS - Carbon Steel, SS - Stainless Steel, AL - Aluminum

Air Plasma/Air Shield, 50 - 65 Amp cuts on Stainless Steel and Aluminum have rough surfaces.

N

2

Plasma/N2 Shield, 50 - 65 Amp cuts of Stainless Steel and Aluminum have fair to good surfaces.

Pilot Arc -- Low

Current

(amps)

pierce

height

in. (mm)

Cutting

height

in.(mm)

arc

Voltage

(Volts)

CS - 1/16 (1.6)

50

220 (5.6)

1/4 (6.4) 5/32 (4)

115

Air - 40 (2.76)

Air - 60 (4.14)

Air - 30 (2.07)

CS - 1/8 (3.2)

120 (3)

112

CS - 1/8 (3.2)

65

120 (3)

1/8 (3.2)

110

CS - 3/16 (4.8)

95 (2.4)

5/32 (4)

118

CS - 1/4 (6.4)

80 (2)

120

Air - 65 (4.48)

CS - 3/8 (9.6)

40 (2)

5/16 (8)

122

SS - 1/16 (1.6)

50

180 (4.6)

1/4 (6.4) 5/32 (4)

111

Air - 40 (2.76)

Air - 60 (4.14)

Air - 30 (2.07)

SS - 1/8 (3.2)

65

80 (2)

119

SS - 1/4 (6.4)

60 (1.5)

118

Air - 65 (4.48)

AL - 1/16 (1.6)

50

180 (4.6)

1/4 (6.4) 1/8 (3.2)

116

Air - 40 (2.76)

Air - 60 (4.14)

Air - 45 (3.1)

AL - 1/8 (3.2)

110 (2.8)

115

AL - 1/4 (6.4)

65

65 (1.6)

5/32 (4)

128

Air - 65 (4.48)

AL - 1/16 (1.6)

50

180 (4.6)

1/4 (6.4) 1/8 (3.2)

118

N

2

- 40 (2.76)

N

2

- 60 (4.14)

N

2

- 30 (2.07)

AL - 1//8 (3.2)

120 (3)

117

AL - 1/4 (6.4)

65

70 (1.8)

125

N

2

- 65 (4.48)

SS - 1/16 (1.6)

50

180 (4.6)

1/4 (6.4) 5/32 (4)

119

N

2

- 40 (2.76)

N

2

- 60 (4.14)

N

2

- 30 (2.07)

SS - 1/8 (3.2)

65

80 (2)

125

N

2

- 45 (3.1)

SS - 1/4 (6.4)

55 (1.4)

127

N

2

- 65 (4.48)

travel

speed

ipm(M/m)

start gas

type/pressure

psi (bar)

plasma gas

type/pressure

psi (bar)

shield gas

type/pressure

psi (bar)

Material

type-thickness

in.(mm)

Summary of Contents for ESP-200

Page 1: ...ESP 200 Plasmarc Cutting System Instruction Manual F15 462 C 02 2008 ...

Page 12: ...12 section 2 description ...

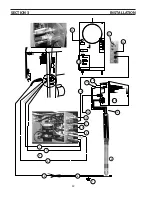

Page 31: ...31 section 3 installation Plumbing box fully connected including setup pendant ...

Page 32: ...32 CE 1 2 3 4 5 6 7 9 10 11 12 13 16 19 20 21 22 15 17 18 14 section 3 installation 8 ...

Page 84: ...84 section 7 replacement parts 1 2 3 4 5 6 7 8 9 10 11 12 13 7 6 Right Inside View ...

Page 88: ...88 section 7 replacement parts 6 1 4 5 6 R ef R ef 2 3 7 8 Back and Top Inside View ...

Page 92: ...92 section 7 replacement parts 1 2 3 4 5 6 7 8 7 10 Remote Setup Pendant P N 37145 ...

Page 100: ...100 notes ...