17

seCtIon 3

InstallatIon

IMproper grounDIng Can result In Death or InJurY.

ChassIs Must Be ConneCteD to an approVeD eleCtrICal

grounD. ensure sYsteM has a gooD earth grounD. see

grounDIng Your Manual.

Be sure grounD leaD Is not ConneCteD to anY prIMarY terMI-

nal.

eleCtrIC shoCK Can KIll! Dangerous Voltage anD Current!

anY tIMe WorKIng arounD a plasMa poWer sourCe WIth CoV-

ers reMoVeD:

Disconnect power source at line (wall) disconnect.

•

Have a qualified person check the output bus bars (positive and nega-

•

tive) with a voltmeter.

WarnIng

WarnIng

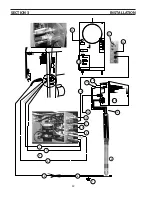

3.5 Connecting pt-26 plasma hand torch

3.5.1 pt-26 and esp-200 output Cables, hoses and adapters (customer supplied)

Hose and cable lengths vary depending on system.

Coolant Return (pilot arc cable inside)

•

Coolant Supply (plasma current cable inside)

•

Switch Lead

•

Shield Gas

•

Plasma Gas

•

Work Cable

•

SEE Description, Section 2 for part numbers.

note:

Do not use the PT-26M (mechanized) on a CNC application. A plumbing box is not available (required

for CNC gas control). Torch can be mounted on a mechanized tractor. An auxiliary pilot arc ON switch is

required when using a PT-26M. See connection procedure for details.

OFF

ON

ESP-200 Console

PT-26 Hand Torch

PT-26M Mechanized Torch

Hand Remote Arc ON Switch

Summary of Contents for ESP-200

Page 1: ...ESP 200 Plasmarc Cutting System Instruction Manual F15 462 C 02 2008 ...

Page 12: ...12 section 2 description ...

Page 31: ...31 section 3 installation Plumbing box fully connected including setup pendant ...

Page 32: ...32 CE 1 2 3 4 5 6 7 9 10 11 12 13 16 19 20 21 22 15 17 18 14 section 3 installation 8 ...

Page 84: ...84 section 7 replacement parts 1 2 3 4 5 6 7 8 9 10 11 12 13 7 6 Right Inside View ...

Page 88: ...88 section 7 replacement parts 6 1 4 5 6 R ef R ef 2 3 7 8 Back and Top Inside View ...

Page 92: ...92 section 7 replacement parts 1 2 3 4 5 6 7 8 7 10 Remote Setup Pendant P N 37145 ...

Page 100: ...100 notes ...