Section 11

•

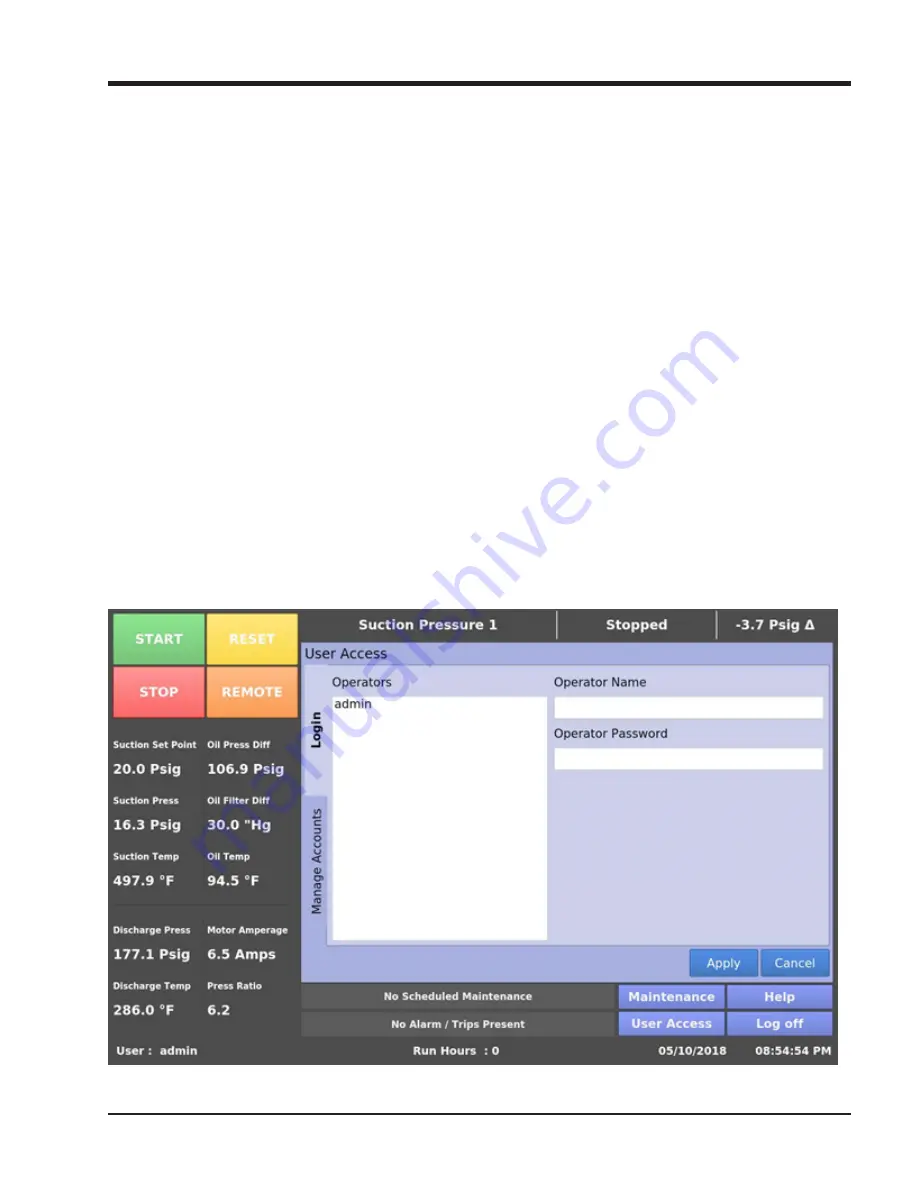

User Access

11 – 1

MicroVission Controller • Operation and Service Manual • Emerson • 35391MV 1.0

Overview

The User Access is the screen where all operators go to

log in.

In the MicroVission, each screen has a security level that

provides the necessary permissions to the operator,

technicians and/or supervisors to modify different sets

of setpoints. The MicroVission has four levels of security,

see Figure 11-1.

• Level 0 – This is the default level where no operator is

logged in. The functions available to the operator are

very limited and basically only allows them to start

and stop the compressor.

• Level 1 – This is a technician level of access. All the

setpoints needed to operate and adjust the perfor-

mance of the compressor will be available to an op-

erator with this level of access.

• Level 2 – This is a supervisor level of access. Setpoints

that require a higher level of knowledge such as cali-

brating instrument will be available to an operator

with this level of access.

• Level 3 – This is considered a contractor level of ac-

cess. The setpoints available at this level have the

most potential of causing damage to the compressor.

Therefore, this access is restricted to those only with

the highest level of competence.

The User Access screen also provides options to add new

operators and modify or delete existing operators. Any

operator can add an additional operator but can only

add operator of lesser or equal security level.

The MicroVission will be shipped with a Level 3 operator

and password pre-assigned to the installing contractor.

The contractor can then assign all users with security lev-

els as needed.

The procedure to assign user access levels is to first press

the User Access button. The User Access screen will ap-

pear with the preassigned level 3 operator name visible

within the “Operators” section. Highlight the name,

then enter the password associated with that name of

the user, then press Enter key to close the keyboard.

Then press the “Apply” button. Press the “Manage

Accounts” tab to begin the process of entering another

Operator name, and assigning password and user level

of this additional user. Lastly – remember to press the

“Add/Update” button to add this user to the list, then

press the “Apply” button before exiting this screen to

make this change permanent.

Figure 11-1. User Access Screen - Login

Summary of Contents for Vilter MicroVission

Page 1: ...MicroVission Controller Operation and service manual Version 1 0 ...

Page 2: ......

Page 4: ......

Page 115: ......