5.

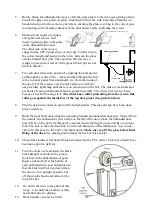

Before fitting the unhanded door post, offer the glass panels to the door (see glazing plan in

booklet for glass size guide on door), slide them in from the side. Carefully attach the un-

handed door post in the same way as before, ensuring the glass is sitting in the correct posi-

tion (sitting on the beading channels of the door posts) before tightening the screws.

6.

Make sure all angles are square

and tighten all screws. Now

insert 2 glazing clips to the glass

on the unhanded door post.

The other side of the door is

clipped using a PVC glass strip (or clip cap). Cut the strip to

the correct length and push into the cavity between the glass

and the handed door post. The cap when fitted acts as a

wedge to prevent movement of the glass. Metal clips are not

fitted to this bar.

7.

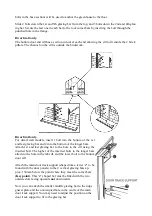

Fix each door wheel into position by pushing the bolt provid-

ed through the centre of the wheel and then through the hole

in the top door panel from underneath (i.e. from the inside of

the door). Put the washer over the bolt and secure with the

nut provided, tightening until there is no movement on the bolt. The nuts are lock-nuts and

are harder to put on than normal nuts in general assembly. The wheel will revolve freely

because it has ball bearings in it.

The wheel has a collar protruding from the centre, this

collar goes against the inside face of the top door panel. (See picture below).

8.

Slip the nylon door skids on each of the bottom panels. This may already have been done

prior to delivery.

9.

Build the right hand door using the remaining handed and unhanded door post. Viewed from

the outside, the handed door post will be on the left of the door, while the unhanded door

post will be on the right. At this point you must decide the height you would like your door

lock. The hole to take the door lock is on the left hand side of the infill panel. You can de-

cide to fit this panel to the 2nd or 3rd panel down.

Make sure you fit the glass before final

fixing of the door.

See glazing plan towards the back of this booklet.

10. Thread the stainless steel backed brush extruder into the PVC carrier. This may already have

been done prior to delivery.

11. Turn the doors over and insert the black

brush draught excluder in the groove

(bolt slot) in the unhanded door posts.

Insert a nut and bolt at the bottom of

each unhanded door post and tighten so

that the brush will not slip down when

the door is in its upright position. Cut

off the surplus brush and carrier at the

top of the bar.

12. Do not fit the door to the gable at this

stage – wait until the structure is fully

assembled prior to glazing.

13. Door handles can now be fitted.

Summary of Contents for 6'3" WIDE THYME

Page 1: ......

Page 2: ......

Page 3: ......

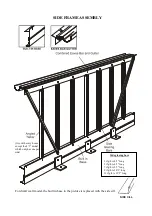

Page 11: ...REAR END ASSEMBLY dotted line indicates corner bracket base leg going into ground ...

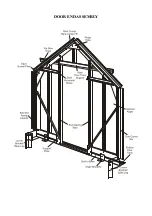

Page 16: ...DOOR END ASSEMBLY ...

Page 19: ...DOOR FRAME ASSEMBLY ...

Page 21: ...ROOF VENT ...

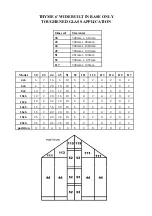

Page 33: ...THYME 6 GLAZING PLAN BUILT IN BASE ONLY ...

Page 35: ...THYME 6 GLAZING PLAN DWARF WALL ONLY ...

Page 36: ...ELITE 1601 ...