®

A NORDSON COMPANY

Ultra TT User's Guide

Version 1.2

1.2

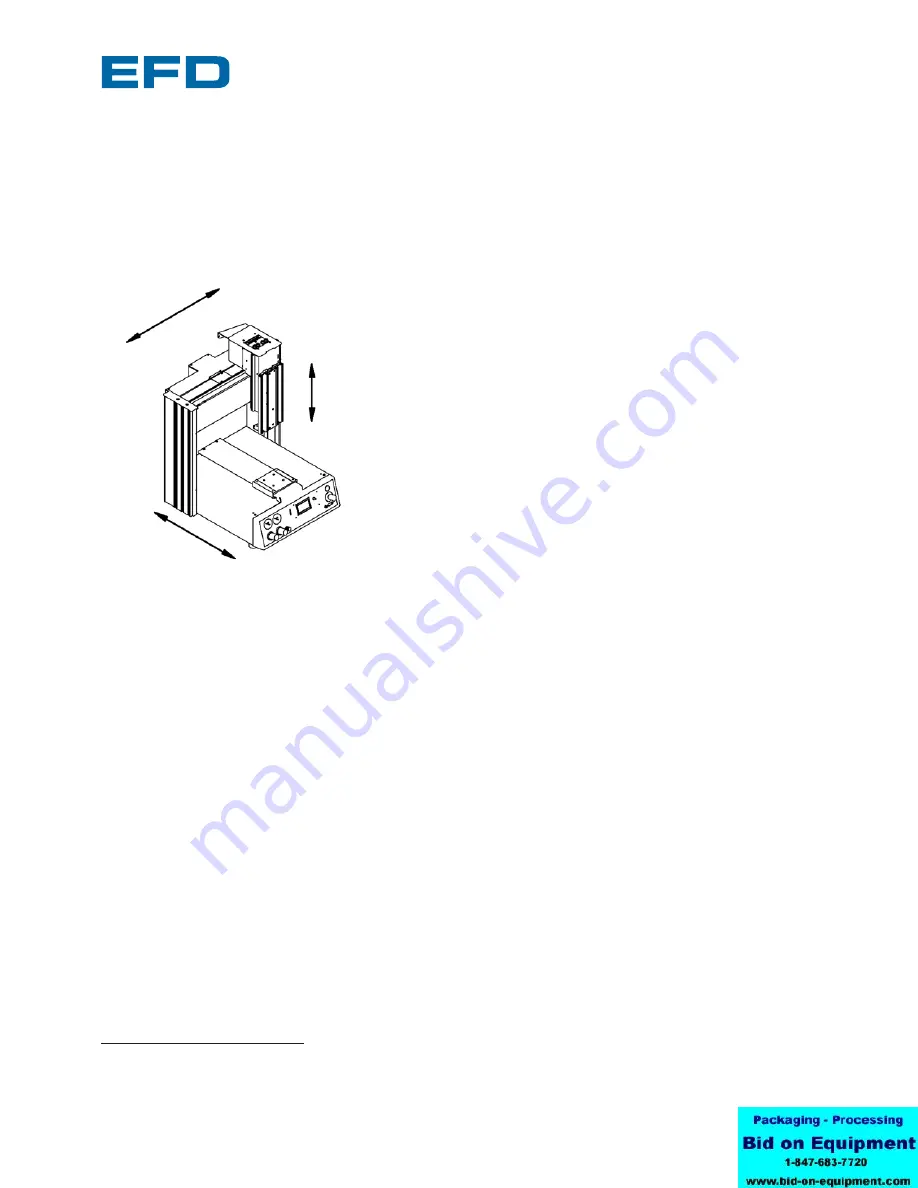

MACHINE MOVEMENTS

The Ultra TT dispensing system uses an advanced microprocessor to simultaneously control three

axes of motion. An optical encoder feedback system provides closed-loop control to accurately

position the dispensing tip whether dispensing lines, dots or contoured paths.

The Ultra TT Automation system is a three-axis

fluid

dispensing

platform. The three degrees of freedom

provided are X/Y/Z. The motions are indicated in the figure

to the left.

The actual strokes of these axes vary depending on the

model. The X-axis movement is side to side. The Y-axis

movement is forward and backward, while the Z-axis

movement is up and down. The mechanical home is

determined by the location of each axes’ home sensor.

In the case of the Ultra TT, the home position is with the

X-axis to the left, Y-axis to the back and Z-axis is up.

1.3

A TYPICAL OPERATION

A typical operation is described below. Note that setup and programming procedures are not

included in the description.

• The part(s) is manually loaded and secured onto the tooling plate

5

.

• Operator activates the system by pressing the start button on the front of the machine.

• The dispensing head then moves to the programmed X/Y position and the height sensor

probe is lowered to establish the correct dispense height based upon the dot or line

parameter dispense gap. If the height sensor is disabled, then the dispensing head simply

moves to the preprogrammed dispense height.

• Fluid is dispensed onto the part, according to the pre-programmed dispensing pattern.

• Once the dispensing procedure is complete, the dispensing head will move back to its

preprogrammed park location.

• When the tooling plate returns to the park location, the completed part can now be

removed from the tooling plate.

• The process is then repeated.

16

5

Purchased from EFD or User to supply their own.

X Axis

Y Axis

Z Axis