Versatrax 300™

Document: UMBH008532.docm

Revision: A07

Created by: KJB

Date: 26 Sep 2019

3047763-A07

Source Location: C:\ePDM\ISLEng\products\bh-vt300series4-trackchassis\manuals\UMBH008532.docm

Page 53 of 67

Versat

rax 30

0 User Ma

nu

al

For IB

A

5954

3. The winch is equipped with a reversible variable speed control (see manufacturers literature,

KBPC-240D) and automatic level wind mechanism.

4. Proper level winding of the tether is important for both the tether life and capacity of the reel.

5. When paying out tether, disengage the drive clutch to allow the vehicle to pull tether directly off

the drum.

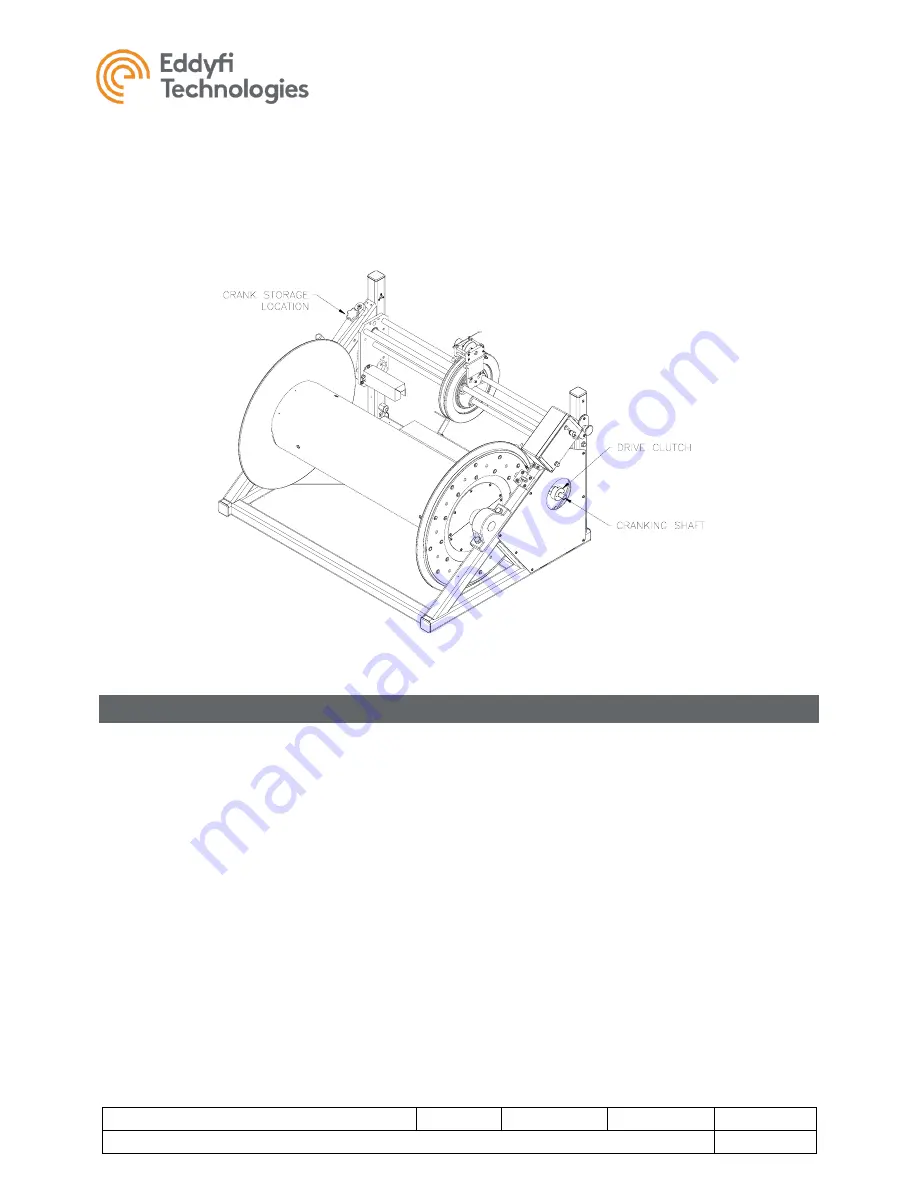

FIGURE 39: WINCH DRIVE CLUTCH LOCATION

Un-spooling The Tether

1.

The first phase of the vehicle’s journey is the initial deployment. Make sure that the tether is not

snap loaded or kinked during the initial deployment.

2. As the vehicle travels, it may pull tether directly off the spool as needed. Ensure that the Drive

Clutch is disengaged.

3. Ensure that the winch is powered on. The winch must be powered for the level wind shuttle to

operate.

4. Make sure the level wind shuttle is moving with the tether as it unspools. Adjust shuttle speed or

direction as necessary. This will prevent any sharp bends while coming off the spool.

5. Always keep some tension on the tether to keep the coils tight on the drum.

6. Do not let slack winds build up on the spool. Such slack winds may get tangled and cause a kink.

They may also fall off the end of the drum and jam.

7. Never fully unspool the tether. The surface end of the tether is anchored to the spool drum. If the

spool is turned past the anchor point, the tether will be broken and require re-termination. Stop

the tether at least one turn before the end and no further. Tape is usually wrapped around the first

five turns as a warning.

8. The winch operator must be in communication with the vehicle operator to co-ordinate stopping

and starting.