8

ENGLISH

the

pumps,

when

starting

and

when

stopping,

manoeuvring the downstream valve.

NB: avoid prolonged operation with the isolating valve

downstream of the system closed, to prevent damaging the

pump (internal overheating).

11. MAINTENANCE

ATTENTION

Extraordinary

maintenance

and

repair

operations must be performed by qualified

personnel (refer to the definition of qualified

personnel in the INTRODUCTION chapter).

Failure to observe this rule voids the warranty

and puts the health of workers and the

efficiency of the set at serious risk.

Every maintenance and repair operation must

be performed with the set disconnected from

the electrical power supply.

Pressure booster sets do not require any particular

maintenance. The operations to perform are divided between

ordinary and extraordinary maintenance operations depending

on the skills required for the relative operation. Also refer to the

instruction manual for the electric pump, the electric panel or

the control device. Any problems can be solved by consulting

the table below. It is recommended in case of a problem not

indicated in the table, for operations indicated in the table that

require the intervention of qualified personnel (refer to the

definition of qualified personnel in the INTRODUCTION

chapter) or for other requirements, to contact your closest

service centre or distributor.

11.1. ORDINARY MAINTENANCE

Ordinary maintenance consists of simple control operations

that can be performed by the operator who uses the set. The

frequency of the checks is indicated in detail for each

operation.

Check the state of wear of the set's electrical cables and

the electrical connections. If breakage or deterioration is

found in the cable's protective sheaths, in the case of

insecure connections or any faults, contact your closest

service centre or distributor. (EVERY 6 MONTHS).

Check that the set is operating efficiency by opening the

valve downstream of the set itself to check that the pumps

start, following the procedure

described in

the

“STARTING THE SYSTEM” chapter. If problems are

found when starting the pumps, contact your closest

service centre or distributor. (MONTHLY).

Check that the hydraulic connections upstream and

downstream of the pressure booster system do not leak

while the system is operating. Check that the system

isolating and stop valves are not clogged. If necessary,

restore the line to its original state. (EVERY 6 MONTHS).

11.2. EXTRAORDINARY MAINTENANCE

Extraordinary maintenance, just like the repair operations, may

only be performed by qualified personnel (refer to the definition

of qualified personnel in the INTRODUCTION chapter).

If faults are found during operation and ordinary maintenance

(see what is described in the ordinary maintenance chapter) or

if abnormal noises or vibrations are detected, stop the set and

immediately contact your closest service centre or distributor

(the complete list of resellers and service centres can be

viewed at

) for the suitable extraordinary

maintenance operations.

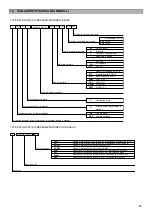

11.3. FAULT AND INTERVENTION TABLE

ATTENTION

For every control below indicated, we suggest ask

support by an EBARA authorized assistance

center.

TROUBLE

CAUSE

SOLUTION

THE PUMP

DOESN'T START

Missing or

interrupted main

voltage

Check the main

voltage presence

Wrong voltage

Pressure sensor

detect wrong

value

Clean or change the

pressure sensor

(on EP-E control

panel only)

Check the proper

scale sensor setting

on the control device

(on EP-E control

panel only)

Pressure

switchies not

properly setted

Check the proper

pressure switches

setting

Stucked control

panel breakers

Check and change

the breakers

Broken fuses

Change the fuses

Overcurrent

protection

operation

Check the proper

overcurrent

protection setting

(see the motor data

and control panel

user manual)

External

protection

operation (e.g.

minimum float

switch)

Check the water

availability and / or

the remote control

proper function

Blocked pump

Check and remove

the blockage causes

Fault motor

Fix or change the

motor

Incorrect setting

of restart

pressure

Check set pressure

and restart pressure

setting

Dry run protection

operation

Check connection of

suction pipes

Check water

availability

Check for air leaks

or infiltrations from

suction pipes

Check correct sizing

of suction pipes

Check correct pump

priming

THE PUMP

DOESN'T STOP

Required working

pressure too high

Set the working

pressure based on

the plant and pump

features

Wrong rotation

sense (low

performances)

Check the rotation

sense and phases

connection

Stuck control

panel breakers

Check and change

the breakers

Pump not

properly primed

and doesn't

achieve required

Properly prime the

pump and check for

air infiltration and/or

leaks

Summary of Contents for GP

Page 2: ......