For more information visit: www.eaton.com

www.eaton.com

www.eaton.com

www.eaton.com

www.eaton.com

Instructions for

VSR-Series Type 5HK

Vacuum Motor Starter

IB01301027E

IB01301027E

Page 26

Page 26

Page 26

Page 26

Page 26

Effective: May 2008

Effective: May 2008

Effective: May 2008

Effective: May 2008

Effective: May 2008

7. Install 4mm x .7 screw securing diode to latch coil bracket and

tighten to 9 lb-in. Do not over tighten, cracking of diode housing

could result.

8. Reassemble all components removed in step 3, insuring steel

shim is between coil core and coil core bracket, and secure 8mm x

1.25 bolt to latch base plate. Insure all components are correctly

aligned and the coil wires are not binding or pinched, Figure 7-15.

9. Reinstall latch assembly and adjust as described in steps 3 to 8

in the section on Installation.

7.6.2 LATCH INSTALLATION

1. Remove the existing roller bracket from the contactor moving

armature, if one is attached.

2. Secure the new roller bracket and bearing assembly with two

6mm x 25mm bolts with lock washers and torque to 85 in-lb (9.6 N-

m). Insure that the side flanges of the roller bracket are parallel with

the end of the armature plate. Note: If bolts longer than 25mm are

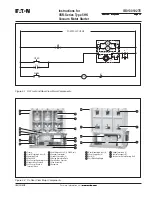

Figure 7-16 Location of Latch Assembly on Conductor

Base Plate

Figure 7-17 Set Gap Between Roller Bearing and Cam to

.5mm (.020”)

used, they will extend through the armature plate and prevent the

contactor from closing and sealing when the main coils are

energized.

3. Locate latch assembly into contactor, see Figure 7-16.

4. Install four 8mm x 1.25 bolts 16mm long, with lock and flat

washers through the bottom of the contactor base plate into the

latch base plate, do not tighten at this time.

5. With contactor energized, place a 0.5mm (0.020 in.) feeler gage

between roller bearing and rotating cam on lath assembly, see

Figure 7-17

FOLLOW NECESSARY PRECAUTIONS INCLUDING INSURING

THAT ALL TRANSFORMERS ARE PROPERLY ISOLATED BEFORE

APPLYING POWER TO CONTACTOR COIL. IF VOLTAGE IS BACK

FED INTO A TRANSFORMER, HIGH VOLTAGE WILL BE GENER-

ATED ON THE TRANSFORMER PRIMARY. HIGH VOLTAGE CAN

CAUSE SERIOUS INJURY OR DEATH.

6. Apply force to latch assembly, sliding cam towards roller

bearing, and tighten four mounting bolts through contactor base-

plate. Torque to 200 in-lb (22.6 N-m).

7. Release the latch by depressing the latch release tab on the

latch assembly. Refer to Figure 7-17.

WHEN RELEASING THE LATCH SEVERAL PARTS OF THE

CONTACTOR WILL MOVE WITH CONSIDERABLE FORCE. USE

CAUTION TO INSURE FINGERS ARE NOT PINCHED AS THE

CONTACTOR IS FORCED OPEN BY THE RETURN SPRING.

8. Route the two control wires from the full bridge diode across the

main coils, connecting them to the main coil control wires with tie

straps, and terminate them at terminals 7 & 8 on the control board.

WARNING

WARNING