For more information visit: www.eaton.com

www.eaton.com

www.eaton.com

www.eaton.com

www.eaton.com

Instructions for

VSR-Series Type 5HK

Vacuum Motor Starter

IB01301027E

IB01301027E

Page 12

Page 12

Page 12

Page 12

Page 12

Effective: May 2008

Effective: May 2008

Effective: May 2008

Effective: May 2008

Effective: May 2008

SECTION 4: INSTALLATION AND INSPECTION

BEFORE PLACING THE STARTER IN SERVICE, CAREFULLY FOLLOW

THE INSTALLATION PROCEDURE BELOW AND THE SAFE PRACTICES

SET FORTH IN SECTION 2. NOT FOLLOWING THE PROCEDURE MAY

RESULT IN INCORRECT STARTER OPERATION LEADING TO DEATH,

BODILY INJURY, AND PROPERTY DAMAGE.

When the starter is first commissioned into service and each time

the starter is returned to service, it should be carefully examined

and checked to make sure it is clean and operating correctly.

4.1 EXAMINATION FOR DAMAGE

Examine the starter for loose or obviously damaged parts. Never

attempt to install nor operate a damaged starter.

4.1.1 NAMEPLATE VERIFICATION

Compare the starter nameplate information with switchgear

drawings for compatibility. Starter and compartment code plates do

match power ratings, but do not match control voltages.

4.2 INITIAL INSPECTION AND OPERATION

Inspect the starter for any damage that occurred during shipment,

storage, and installation.

Set the dip switches in the coil control board for the proper control

voltage and dropout time (Figures

4-1

and

4-2

and Tables

4.1

and

4.2

). When control information is supplied, dip switches will be

factory set.

Sequence the control circuit, including closing the starter with the

main power circuits de-energized and locked out.

Verify that the starter will be connected to an incoming power

supply and outgoing load with characteristics agreeing with the

starter rating and coil burden requirements.

WARNING

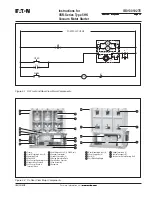

Figure 4-1 Coil Control Board with Dip Switch

Figure 4-2 Coil Control Board Removal

1 2 3 4 5 6

ON

OFF

Dip S

w

itch

Table 4.1 - Dip Switch Setting-Control Voltage

g

n

i

t

t

e

S

1

W

S

2

W

S

3

W

S

z

H

0

5

c

a

V

0

1

1

f

f

O

f

f

O

f

f

O

z

H

0

6

c

a

V

0

2

1

n

O

f

f

O

f

f

O

z

H

0

5

c

a

V

0

2

2

f

f

O

n

O

f

f

O

z

H

0

6

c

a

V

0

4

2

f

f

O

n

O

f

f

O

C

D

V

5

2

1

f

f

O

f

f

O

n

O

g

n

i

t

t

e

S

y

a

l

e

D

4

W

S

5

W

S

6

W

S

s

m

0

3

f

f

O

f

f

O

f

f

O

s

m

0

5

n

O

f

f

O

f

f

O

s

m

0

3

1

f

f

O

n

O

f

f

O

s

m

0

5

2

n

O

n

O

f

f

O

s

m

0

3

3

f

f

O

f

f

O

n

O

Table 4.2 - Control Board Dropout Settings

4.3 VACUUM INTERRUPTER INTEGRITY

Using a dry lint free cloth or a paper towel, clean all the insulating

surfaces of the pole units. Conduct a vacuum interrupting integrity

check as described in Section 6.2.