DESCRIPTION:

DATE:

DRAWING NO:

INSTALLATION NOTES

SHEET:

REVISION:

F

164201118−1

041500

14 of 19

Customer Information

A−15

EATON

Powerware

®

9315 UPS (300–500 kVA) Installation Manual

S

164201118 Rev H

www.powerware.com

1.

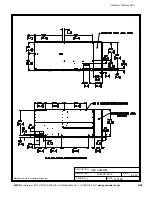

The UPS equipment operating environment must meet the size and weight requirements

shown in Table N, according to your UPS system configuration:

Table N. Equipment Weight

Component

Weight

(Kg (lb)

Shipping

Installed

UPS Cabinet (Powerware 9315 400)

(400/400 System)

2812 (6200)

2767 (6100)

UPS Cabinet (Powerware 9315 500)

(480/480 System)

2812 (6200)

2767 (6100)

UPS Input Transformer Cabinet (480/480)

1860(4100)

1814(4000)

UPS Input Transformer Cabinet (208/208)

1860(4100)

1814(4000)

UPS Input Transformer Cabinet (600/600)

1860(4100)

1814(4000)

UPS Output Transformer Cabinet (208/208)

1860(4100)

1814(4000)

UPS 5% Input Filter Cabinet (480/480)

2182(4800)

2136(4700)

2.

The basic environmental requirements for operation of the UPS system are:

Ambient Temperature Range:

0−40°C (32−104°F)

Recommended Operating Range:

20−25°C (68−77°F)

Maximum Relative Humidity:

95%

Summary of Contents for 9315

Page 1: ...Powerware 9315 UPS 300 500 kVA Installation Manual ...

Page 97: ......

Page 98: ... 164201118H 164201118 H ...