17

CC 100 M100EN1

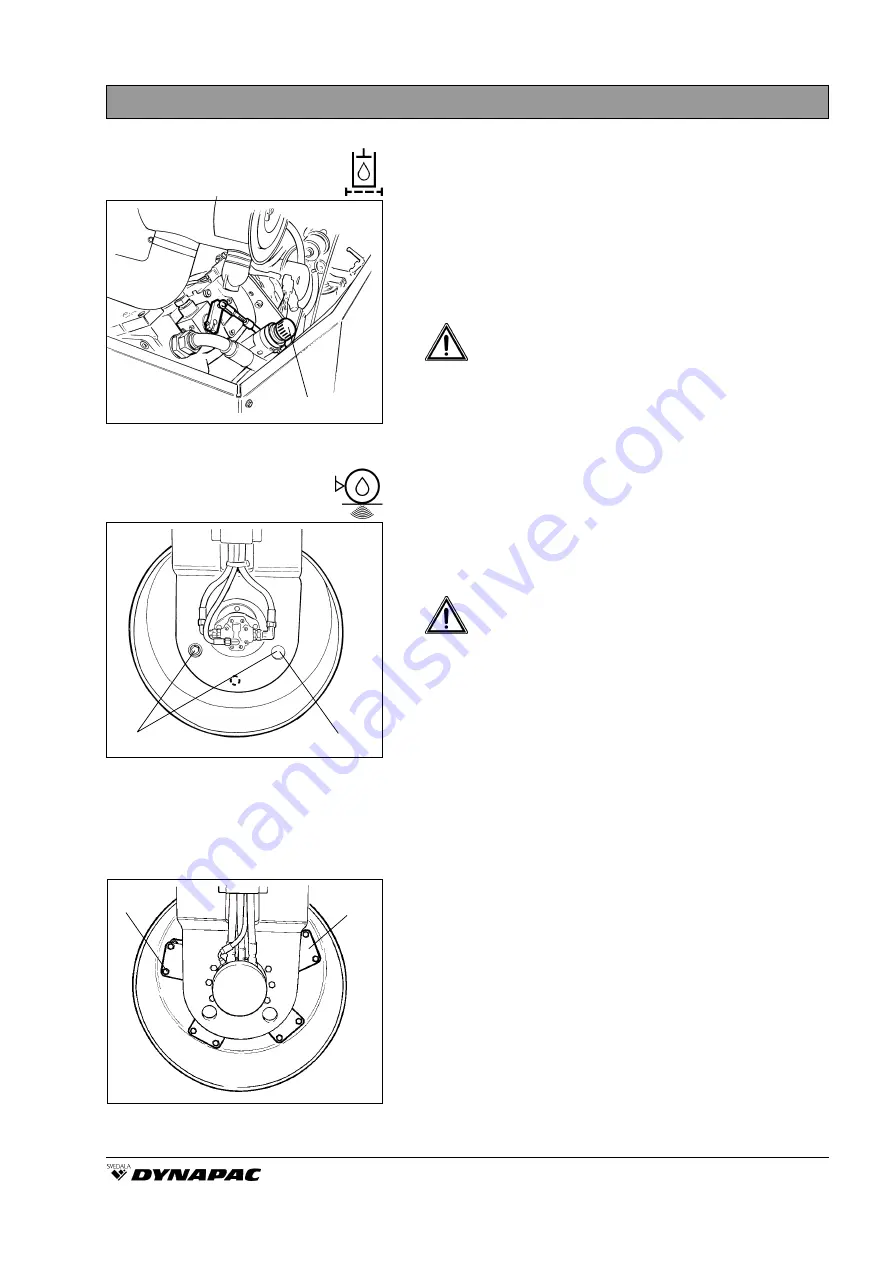

Hydraulic reservoir cap

Checking

Make sure that the reservoir cap is not clogged. Air

must be able to flow freely in both directions through

the cap. Clean with a little diesel oil if either direction is

clogged, and blow clear with compressed air to ensure

free flow. Replace the cap with a new one if this cannot

be done.

Wear protective goggles when working

with compressed air.

Drum -

Checking the oil level

2

1

Fig. 21 Drum, vibrator side

1. Oil plug

2. Inspection hole

1

1. Position the roller on a level surface and drive slowly

forward until the oil plug (1) is in line with one of the

inspection holes (2).

Switch off the engine and push the

reserve/parking brake knob.

2. Screw out the plug and ensure that the oil level

reaches the lower edge of the hole. Top up with

fresh transmission oil as required, see page 3 with

regard to the right quality of the oil.

3. Clean the magnetic oil plug (1) to remove any metal

particles and then refit the plug.

EVERY 500 HOURS OF OPERATION (Every 3 months)

Fig. 20 Engine compartement

1. Reservoir cap

1. Make sure that the rubber elements are undamaged

and free from cracks.

2. Check that the mounting bolts are tight.

3. Change all the elements if more than 25% on one

side of the drum have cracks that are deeper than

10 to 15 mm. (1/2 in.)

4. Check the rubber elements on both sides of the

drum.

Rubber elements and fastening

bolts - Checking

Fig. 22 Drum suspension

1. Rubber element

2. Fastening bolts

2

1

Summary of Contents for CC100

Page 2: ......