14

EN

2.00.390C - 1 User’s Manual

D Ü P E R T H A L S i c h e r h e i t s t e c h n i k G m b H & C o . K G

Frankenstr. 3

63791 Karlstein, Germany

Version March 2022

such damage would not be covered by the product warranty.

3.4 Setting the Pressure Difference

At a metering orifice, the suction line from the storage cabinet is equipped

with a pitot probe. The pressure difference it senses is measured by a dif

-

ferential pressure meter via the two transparent tubes routed to it. It rises

as the airflow through the suction-side extraction line on site increases.

With restricted or blocked airflow, the pressure difference sensed by the

probe drops. If it drops below the threshold set at the differential pressure

meter, a signal that an error condition has developed is sent into the en-

closure for further processing via the cable in the blue protective conduit.

For technical reasons (hysteresis), the threshold from which the monitor

cancels the error condition when the pressure difference rises again, is

a little higher than the threshold that triggers an error. Therefore, make

sure at all times that the settings for the pressure difference and the fan

speed of the air extraction system on site are matched to each other in

such a way that both an error is indicated when a restriction is detected,

and the error is canceled by the unit when the restriction is cleared. There

is no upper threshold for a maximum pressure difference.

The value of the pressure difference threshold can be set at the

meter from 20 Pa to 300 Pa. This is done by simply removing the

transparent cover and using a screwdriver in the provided slot to

turn the selector. The factory-set default threshold of the pressure

difference is 70 Pa.

Setting the pressure difference threshold for monitoring the airflow

requires the following steps:

1. Connect the exhaust air monitoring unit properly to the ex-

traction system (outlet nipple) on site. Pay attention to the

installation of the sleeve of the differential pressure meter; it

has to tee into the line so the airflow passes through it in the

direction of the arrow.

2. Set the fan speed to the desired extraction airflow (see the

operator instructions of the fan system on site).

Caution

In a cabinet for flammable liquids, the extraction airflow

has to be sufficient to replace the interior volume of the

cabinet 10 times every hour.

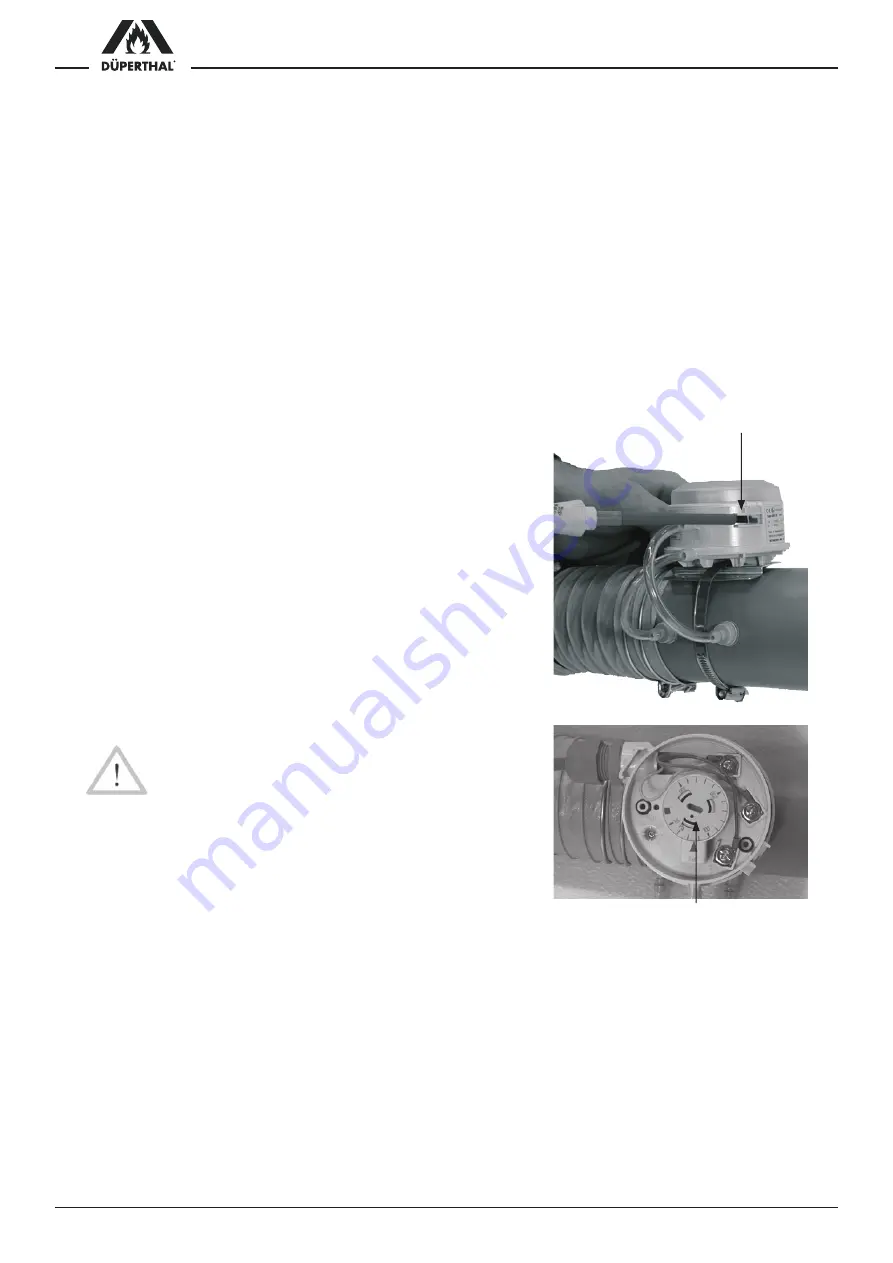

3. Loosen the plastic cover of the differential pressure meter on

the suction hose (refer to the photograph to the right).

4. Using an appropriate screwdriver in the turning selector at the

center of the differential pressure meter, set the threshold to

make “Exhaust OK” appear on the screen (reduce pressure

difference). If no error is displayed on the screen at the start, the

pressure difference setting may first be increased until an error is

displayed, then slowly reduced again. The higher the pressure dif

-

ference threshold is set, the quicker / more sensitive the meter will

respond by throwing an error message.

5. Using appropriate means on site (e.g. by covering the exhaust outlet

with your hand), interrupt the extraction airflow temporarily.

6. If set correctly, the unit will trigger the audible alarm and display

the error message on the screen. After the airflow interruption is

cleared, the audible alarm should stop and the “Confirm error” mes-

sage should appear on the screen.

7. Reinstall the plastic cover on the differential pressure meter.

8. Confirm the error message on the screen by pressing the START/

SET key to re-open the dry contacts.

Latch clips to hold/remove

the plastic cover

Selector for setting the

pressure difference threshold

Summary of Contents for HNA-18 II ATEX F

Page 2: ......