/Kits/1296-144CK.doc

7

8/15/2011

7. Attach the PCB to the pallet. Use two 4-40 x 3/16” screws by the antenna connector and

two 4-40 x 1/4 screws with #4 flat washers by the oscillator section. If you find solder interference

between the PCB and the pallet, remove it by wicking or filing!

8. Attach the connector panel to the pallet. Review the configurations below. Your panel

has all of the holes in it. You may install all of the connectors or just the connectors you desire.

Trim the Teflon on the connectors flush with the panel. Use the 3-48 screws for the SMA

connectors or 4-40 screws for the N connector. The longer 3/8” screws go through the connector

and panel, then into the pallet. The short 3/16” screws hold the connectors to the panel. You may

use the screws to plug the holes if you do not use the connector. After the connectors are

installed, verify that the panel is a flush mount with the pallet and then solder the pins. If you need

to re-position the PCB for the panel to be flush, do so.

9.

Use the bottom side component placement as a guide and wire the connections with the

supplied #24 Teflon wire. Install them all as shown. The connection from the +13 VDC connection

and the RCA connector is done with the heavier green wire. Make the connection from the PTT

connector to the PCB. Install the ground lugs as shown with the short 1/8” 4-40 screws and solder

the 1000

ρ

F caps in place.

10. Find the bottom half of the enclosure (the one with the holes in it) and line up the pallet

with the mounting holes. Insert any two 4-40 x 7/16” screws and start them. Install 2 flat head

screws in the rear panel. Be sure the wires are clear of the ribs and filters and tighten all screws.

If the pallet wobbles, something is being pinched!! Insert the switch into its position but do not

solder. Install the switch panel with 2 flat head screws then solder the exposed leads of the

switch. Install the LED’s. The short lead is ground. Now remove the pallet from the enclosure

and trim all excess leads from the bottom side of the PCB and solder the mounting leads of the

switch.

11. Attach the M67715 to the pallet. Use the thermal compound supplied, line up the pins

with the PCB and use the 4-40 x 1/4 “ screws. Solder the 5 pins. Now make a determination of

what keying scheme you will use, PTT-H (+ voltage) or PTT-L (Ground to transmit) and make the

appropriate jumper connection from the PTT connection on the top side of the PCB.

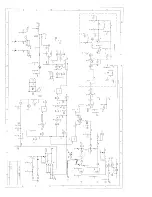

12. Using the matrix below, make a determination of the required IF drive level and decide

if you want a common or split IF. All IF drive levels may be achieved from 1 mW to 10 watts by

following the supplied schematic, matrix, and simplified component layout. The 50 ohm load

(R36) is mounted on the front panel and is installed after the pallet is aligned with the front panel

during final test.

13. Install the IF coax between the IF connector (s) on the rear panel and their proper

locations on the PCB. Refer to the custom pictorial for the correct configurations.

Summary of Contents for 1296-144 CK

Page 16: ......