/Kits/1296-144CK.doc

4

8/15/2011

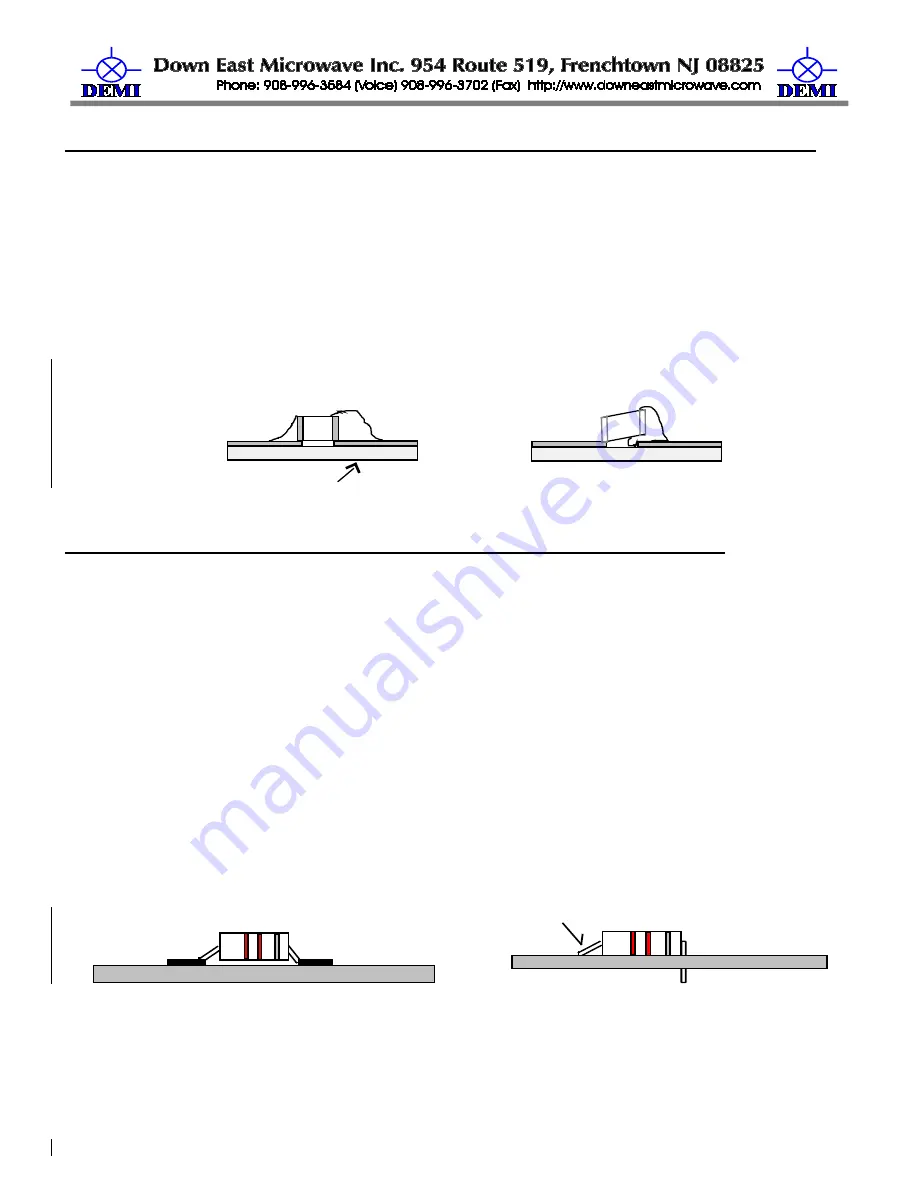

Soldering surface mounted passive components such as chip resistors and capacitors:

1. Determine the component mounting position based on the assembly diagram.

2. Without the component, tin one of the mounting pads not shared by another component.

(Flow a small amount of solder on it)

3. After cooling, place the component in the correct position per the assembly diagram, it

should now have one end over the tinned area.

4. Holding the component in place with tweezers or other soldering aid, heat the tinned area

and allow the solder to flow around the component. Remove the heat.

5. Once solidified, remove holding tool and heat and flow solder to the other side of the

component only if it is not shared by a second component. If so, solder the component that

shares the pad first. You are done! See examples in figure 3.

Circuit board

Correct

Incorrect

Solder Fillet

Incorrect Component

Placement

Figure 3. Proper SMD Assembly.

Soldering leaded components (resistors, capacitors, diodes, and inductors) :

Depending on your available tools, you can solder your transverter's leaded components

from either the top or bottom of the PCB. It is suggested for the home assembler to use a method

that is comfortable. A simple holding vise can be utilized to allow the components to be 'dropped

in' from the top side and soldered on this side without flipping over the assembly. As an alternate

method, you can insert one component at a time in the correct mounting location and gently push

down to the circuit board, while holding the component, flip over the circuit board and bend the

leads over in opposite direction to hold the component in place. Although this is the most reliable

method, there are some drawbacks if the component must be removed when the PCB is installed

in the enclosure.

Some leaded components may need to be surfaced mounted either on one or more leads.

If this is the case, the leads need to be pre-formed before soldering. If you see a leaded

component on the component placement diagram without a circle at the end of the lead such as

R25 and C49, those leads will need to be surfaced mounted as shown in the drawings below. DO

NOT install any leaded components in the ground via holes if it is shown as a surface mount lead.

The PCB mounts to a pallet and if there is any solder or extended lead interference, the PCB will

not be flush with the pallet.

Leads soldered to PCB surface

Circuit Board Surface

This end soldered to PCB surface

Circuit Board Surface

Figure 4

.

Some inductors are pre-formed and some will need to be formed such as L1. It is

suggested that the coils be formed on the supplied wooden dowel. Winding coils is not an exact

science and you should not be intimidated by it. Using the enamel wire supplied, extend about ¼"

in a perpendicular direction off of the dowel and wind the wire around it, counting each revolution

as one turn. When the total number of turns is completed (see the component list) cut the wire an

Summary of Contents for 1296-144 CK

Page 16: ......