Prodigy Max Operator’s Manual

9

2.2

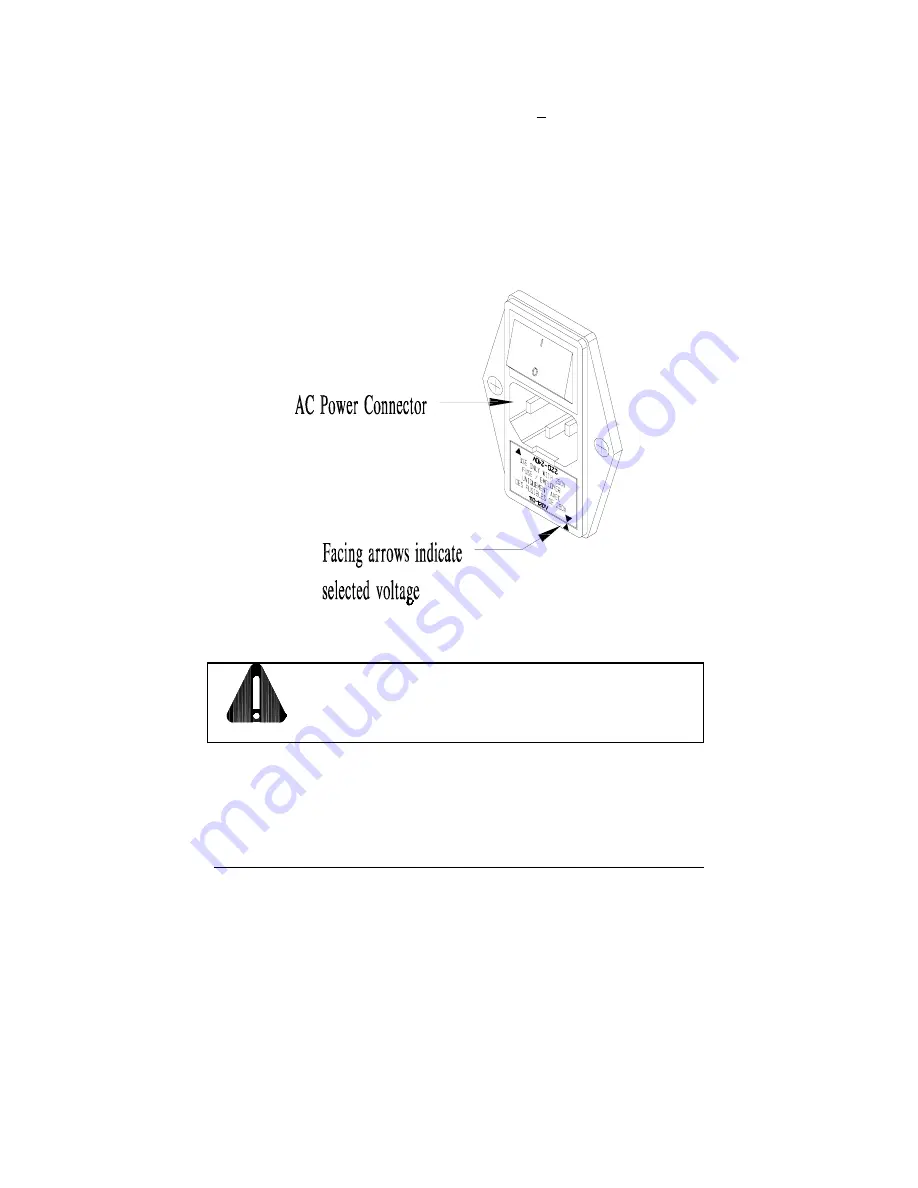

Checking the AC Power Requirements

The standard Printer is configured for 115 VAC +10% single-phase

50/60 Hz with a properly-grounded outlet. A small sticker next to the

power cord connection states the power requirements.

The Printer is also manufactured for 230 VAC operation, most of these

Printers are shipped to international markets. If you are uncertain as to

the power requirements of the Printer, or the outlet you are connecting to,

check with a qualified service technician to verify the installation before

connecting AC power.

CAUTION

Check the rear AC switch settings before applying

power. The facing arrows must by selected to match the

supplied voltage rating, (115VAC or 230VAC).

Summary of Contents for Prodigy Plus

Page 1: ...Prodigy Plus Operator s Manual ...

Page 4: ......

Page 6: ......

Page 12: ...Getting Started 4 Prodigy Plus Figure 1 3 Mechanism Detail Figure 1 4 Rear View ...

Page 44: ...Troubleshooting 36 Prodigy Plus ...

Page 55: ...Available Fonts and Barcodes Prodigy Plus C 5 Prodigy Plus 152 Font 4 continued ...

Page 58: ...Available Fonts and Barcodes C 8 Prodigy Plus Prodigy Plus 152 Font 6 continued ...

Page 61: ...Available Fonts and Barcodes Prodigy Plus C 11 Prodigy Plus 152 Font 9 continued ...

Page 66: ......

Page 68: ...D 2 Prodigy Plus ...

Page 84: ...Warranty Information G 4 Prodigy Plus ...

Page 85: ...Prodigy Max Operator s Manual ...

Page 92: ...ii Prodigy Max Operator s Manual Figure 1 1 Overall View ...

Page 117: ...Prodigy Max Operator s Manual 27 Figure 3 1 Front Panel ...

Page 129: ...Prodigy Max Operator s Manual 39 Table 3 1 Internal Dip Switch Settings ...

Page 133: ...Prodigy Max Operator s Manual 43 ...

Page 154: ......

Page 156: ...A 2 Prodigy Max Operator s Manual US 31 1F 63 3F _ 95 5F 127 7F ...

Page 158: ......

Page 165: ...Prodigy Max Operator s Manual B 7 ...

Page 166: ...B 8 Prodigy Max Operator s Manual Barcode O ...

Page 167: ...Prodigy Max Operator s Manual B 9 Barcode S Barcode T Barcode z ...

Page 168: ......

Page 170: ...C 2 Prodigy Max Operator s Manual ...

Page 175: ...Prodigy Max Operator s Manual D 5 ...

Page 176: ......

Page 178: ...C 2 Prodigy Max Operator s Manual ...