Check that

parameter 1-93 Thermistor Source

selects terminal 53 or 54.

•

When using terminal 18, 19, 31, 32, or 33 (digital

inputs), check that the thermistor is connected

correctly between the digital input terminal used

(digital input PNP only) and terminal 50. Select

the terminal to use in

parameter 1-93 Thermistor

Source

.

WARNING/ALARM 13, Over current

The peak current limit of the frequency converter (approxi-

mately 145–177% of the frequency converter rated current)

is exceeded. The warning lasts approximately 1.5 s, then

the frequency converter trips and issues an alarm. Shock

loading or quick acceleration with high-inertia loads can

cause this fault. If the acceleration during ramp-up is quick,

the fault can also appear after kinetic back-up.

If extended mechanical brake control is selected, a trip can

be reset externally.

Troubleshooting

•

Remove the power and check if the motor shaft

can be turned.

•

Check that the motor size matches the frequency

converter.

•

Check that the motor data is correct in

parameters

1-20

to

1-25

.

ALARM 14, Earth fault

There is current from the output phases to ground, either

in the cable between the frequency converter and the

motor or in the motor itself.

Troubleshooting

•

Remove power to the frequency converter and

repair the ground fault.

•

Check for ground faults in the motor by

measuring the resistance to ground of the motor

cables and the motor with a megohmmeter.

ALARM 16, Short circuit

There is short-circuiting in the motor or motor wiring.

Troubleshooting

•

Remove the power to the frequency converter

and repair the short circuit.

WARNING/ALARM 17, Control word timeout

There is no communication to the frequency converter.

The warning is only active when

parameter 8-04 Control

Word Timeout Function

is NOT set to

[0] Off

.

If

parameter 8-04 Control Word Timeout Function

is set to

[5]

Stop and Trip

, a warning appears, and the frequency

converter ramps down to a stop and shows an alarm.

Troubleshooting

•

Check the connections on the serial communi-

cation cable.

•

Increase

parameter 8-03 Control Word Timeout

Time

.

•

Check the operation of the communication

equipment.

•

Verify that proper EMC installation was

performed.

ALARM 30, Motor phase U missing

Motor phase U between the frequency converter and the

motor is missing.

Troubleshooting

•

Remove the power from the frequency converter

and check motor phase U.

ALARM 31, Motor phase V missing

Motor phase V between the frequency converter and the

motor is missing.

Troubleshooting

•

Remove the power from the frequency converter

and check motor phase V.

ALARM 32, Motor phase W missing

Motor phase W between the frequency converter and the

motor is missing.

Troubleshooting

•

Remove the power from the frequency converter

and check motor phase W.

ALARM 38, Internal fault

When an internal fault occurs, a code number defined in

is shown.

Troubleshooting

•

Cycle power.

•

Check that the option is properly installed.

•

Check for loose or missing wiring.

Note the code number before contacting the supplier or

Danfoss Service Department.

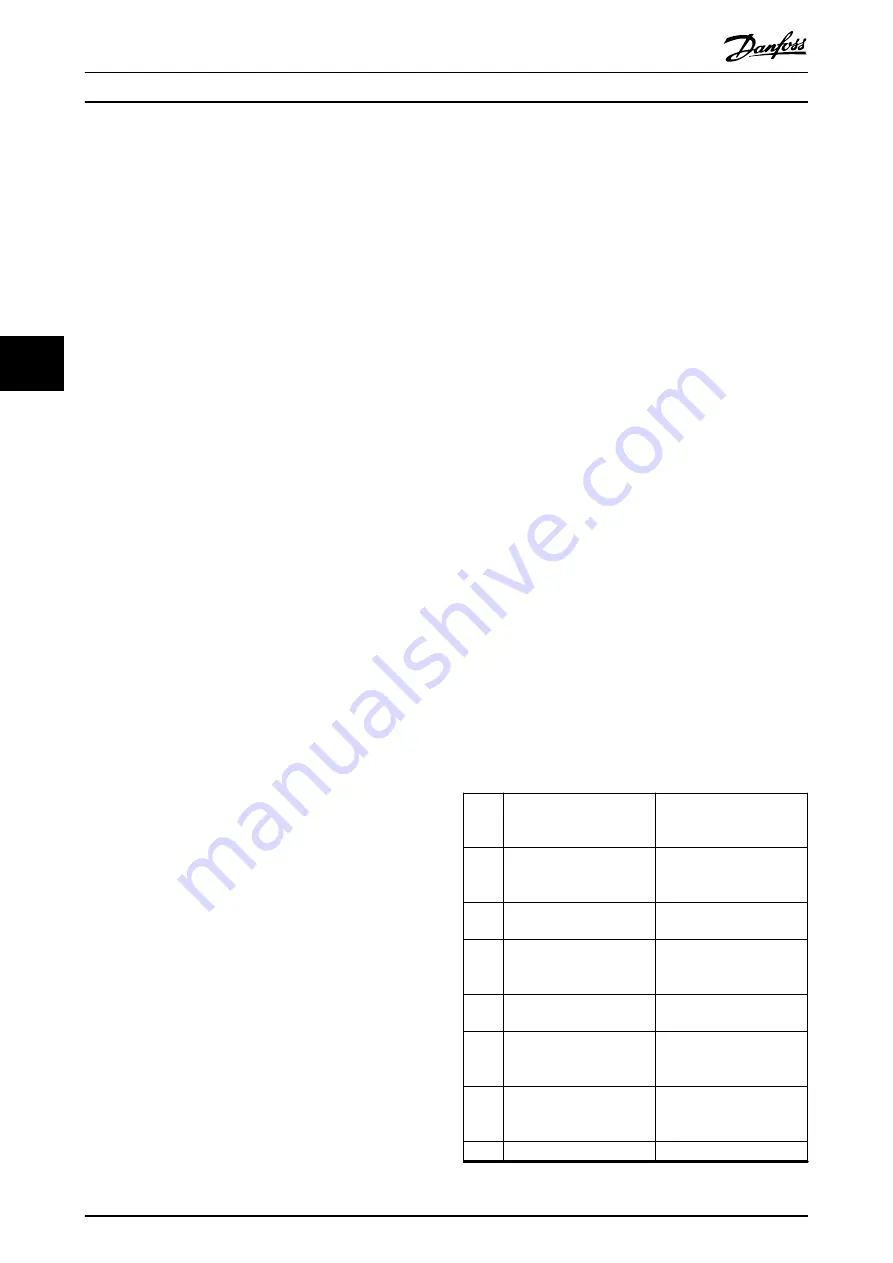

Code

num-

ber

Text

Troubleshooting

0

Serial port cannot be

initialized.

Contact the supplier or

Danfoss Service

Department.

256–

258

Power EEPROM data is

defective or too old.

Replace power card.

512–

519

Internal fault.

Contact the supplier or

Danfoss Service

Department.

783

Parameter value outside of

min/max limits

–

1024–

1284

Internal fault.

Contact the supplier or

Danfoss Service

Department.

1379–

2819

Internal fault.

Contact the supplier or

Danfoss Service

Department.

2561 Replace control card

–

Diagnostics and Troubleshoo...

VLT

®

DriveMotor FCP 106/FCM 106

124

Danfoss A/S © 11/2015 All rights reserved.

MG03N202

5

5

Summary of Contents for VLT DriveMotor FCP 106

Page 2: ......