31.

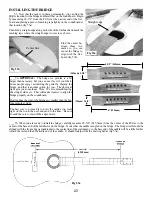

____60. The nut needs to be notched for spacing the strings evenly across

the width. We like to leave about 1/8” (3mm) space at each side before

the first and last notches. Then we try to space the other 4 notches evenly

between them.

The exact spacing for your guitar will depend on the overall width of the

fretboard at the nut. If you have 45 mm total width, then you can put the first

and last notch 3mm from each side, and space the rest of them 8mm apart,

as shown in fig 60a.

Notice that we use tape to hold or ruler to the fretboard, and another piece of

tape on the nut for drawing our notch positions.

If you don’t have the same width on your guitar, then we recommend using

on of the patterns printed below. If necessary, you could have one of these

illustrations slightly enlarged or reduced to suit your instrument.

Fig 60a

1-3/4” NUT

1-13/16” NUT

1-7/8” NUT

Once you have your notches marked evenly across the nut, you

need to cut slots for the strings at each position. Since the strings

vary in thickness, you should make sure your slots will accom-

modate them all. An experienced luthier will keep a set of nut

files in different sizes so he can cut each slot for each particular

string, but that is not necessary on this kit.

You can cut these notches using a very small “V” shaped needle

file or triangle file. You just need to file them deep enough to

make sure the strings will rest firmly on the #0 fret. You’ll need

to angle the file downward toward the peghead, and avoid cut-

ting into the #0 fret, as shown in fig 60b. We like to cover the

peghead with thin cardboard to protect it from being scraped

accidentally by the file.

POINT OF INTEREST

Normally, the notches in the nut would have to be filed to a specific depth to support the strings at the right height above the frets.

For this kit, however, the #0 fret holds the strings at the correct height, and the notches only serve to separate the strings evenly

across the width. This saves you some headache and guesswork at the end of the project.

Fig 60b

card

board

cover

Then flip the peghead over and insert the

threaded sleeves and washers. Use a 716”

nut driver or small adjustable wrench to

tighten the sleeves firmly (fig 61b).

Fig 61a

Fig 61b

Pre-drill for the tiny screws with the

1/16” drill bit provided (fig 61c). Then

install the screws using a #1 size Phil-

lips screwdriver.

Fig 61c

____61. Press the geared tuners into

the peghead from the back side (fig

61a). If they are a bit tight, you can

clean the inside of the holes a little

with a rat-tail file to make them easier

to press in. Orient the handles so they

look evenly spaced and straight.

Summary of Contents for PARLOR

Page 36: ......