4-27

Required

vaccum

degree

Freezing

point

Ambient

temperature

range

–20 –10

0

10

20

30

40

50

60

70

80

Temperaturte (

°

C)

0

60

160

260

360

460

560

660

670

680

690

700

710

720

730

740

755

760

Gauge pressure (

–

mmHg)

Absolute pressure (mmHg)

760mmHg

700

600

500

400

300

200

100

90

70

60

50

40

30

20

10

5

0mmHg

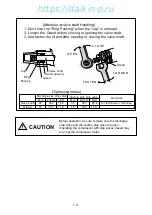

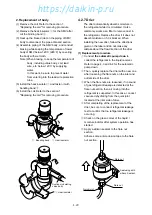

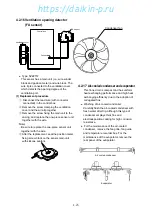

4.2.21 Evacuation and dehydrating

After repairing the refrigerant system, vacuum-

dehydrate the system before charging the

refrigerant.

Vacuum-dehydrating is the process to make the

circuit dry by purging the moisture (liquid) in the

circuit to outside in state of vapor (gas) using the

vacuum pump.

As the pressure lowers below normal atmosphere

(760mmHg), the boiling point of water rapidly

drops. If the boiling point drops beyond the

atmospheric temperature, water will be vaporized.

Example: If the atmospheric temperature is 7.2 ˚C

(45 ˚F), vacuum-dehydrating will be

impossible unless the vacuum degree is

lower than –752mmHg. For vacuum-

dehydrating, it is important to select and

maintain the vacuum pump.

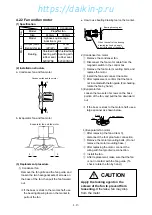

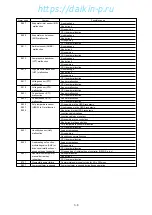

(1) Vacuum pump selection

Select a vacuum pump considering the

following two points.

q

Select a vacuum pump whose vacuum

achievability is excellent.

(A vacuum degree of –755mmHg or lower

can be achieved.)

w

The displacement must be relatively large

(approx. 40

r

/min. or more).

Before vacuum-dehydrating work, be sure

to confirm that the pump achieves the

vacuum degree of –755mmHg or lower by

using the vacuum gauge.

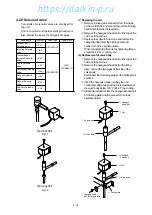

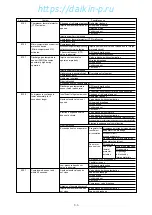

Boiling point of water (˚C) Atmospheric pressure(mmHg) Vacuum degree(mmHg)

40

55

–705

30

36

–724

26.7

25

–735

24.4

23

–737

22.2

20

–740

20.6

18

–742

17.8

15

–745

15.0

13

–747

11.7

10

–750

7.2

8

–752

0

5

–755

Take care that this type is often used as the

most convenient type.

With the pump of an oil rotary type, it is

important to replace the oil and check the

achievability every 1 to 2 months.

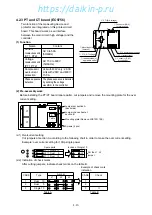

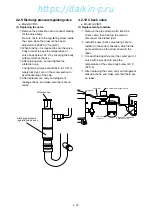

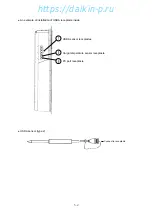

(2) Vacuum-dehydrating method

There are two method of vacuum-

dehydrating of normal vacuum-dehydrating

and special vacuum-dehydrating. In general,

the normal vacuum-dehydrating is applied. If

any moisture is enters the circuit, apply the

special vacuum-dehydrating method.

[normal vacuum-dehydrating]

q

Vacuum-dehydrating(first time)

Connect the gauge manifold to the service

ports of the liquid line and the outlet of

discharge pressure regulator. Run the

vacuum pump for 2 hours or longer. (The

achievable vacuum degree must be –755

mmHg or lower)

If a pressure of –755mmHg or lower can not be

achieved even after pump operation of 2 hours,

moisture or leakage may exist in the system. In

this case, run the pump another hour or more.

If a pressure of –755mmHg or lower can not be

achieved even after operation of 3 hours or

more, check for leakage.

Note: Evacuate the system from the

service ports

r

of both liquid and

outlet of the check valve

t

,

because the system is blocked on

the way since the liquid solenoid

valve is provided on the way of the

system.

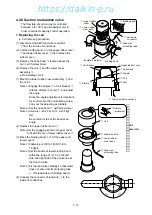

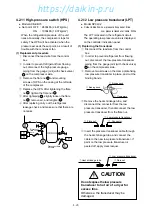

(Reference) Kinds of vacuum pumps and achievable vacuum degree

Achievable vacuum degree

Application

Type

Displacement

For vacuum-dehydrating For air exhausting

Oil rotary type

–759.98mmHg

Applicable Applicable

(oil-necessary type)

100

r

/min.

–750mmHg

Inapplicable Inapplicable

Oilless rotary type

50

r

/min.

(oil-unnecessary type) –759.98mmHg

Applicable Applicable

40

r

/min.

https://daikin-p.ru