8

|

Piping installation

Installer reference guide

83

ERGA04~08EAV3(A) + EHBH/X04+08EA/EJ6V+9W

Daikin Altherma 3 R W

4P629085-1 – 2020.08

NOTICE

Take the following precautions on refrigerant piping into account:

▪

Avoid anything but the designated refrigerant to get mixed into the refrigerant

cycle (e.g. air).

▪

Only use R32 when adding refrigerant.

▪

Only use installation tools (e.g. manifold gauge set) that are exclusively used for

R32 installations to withstand the pressure and to prevent foreign materials (e.g.

mineral oils and moisture) from mixing into the system.

▪

Install the piping so that the flare is NOT subjected to mechanical stress.

▪

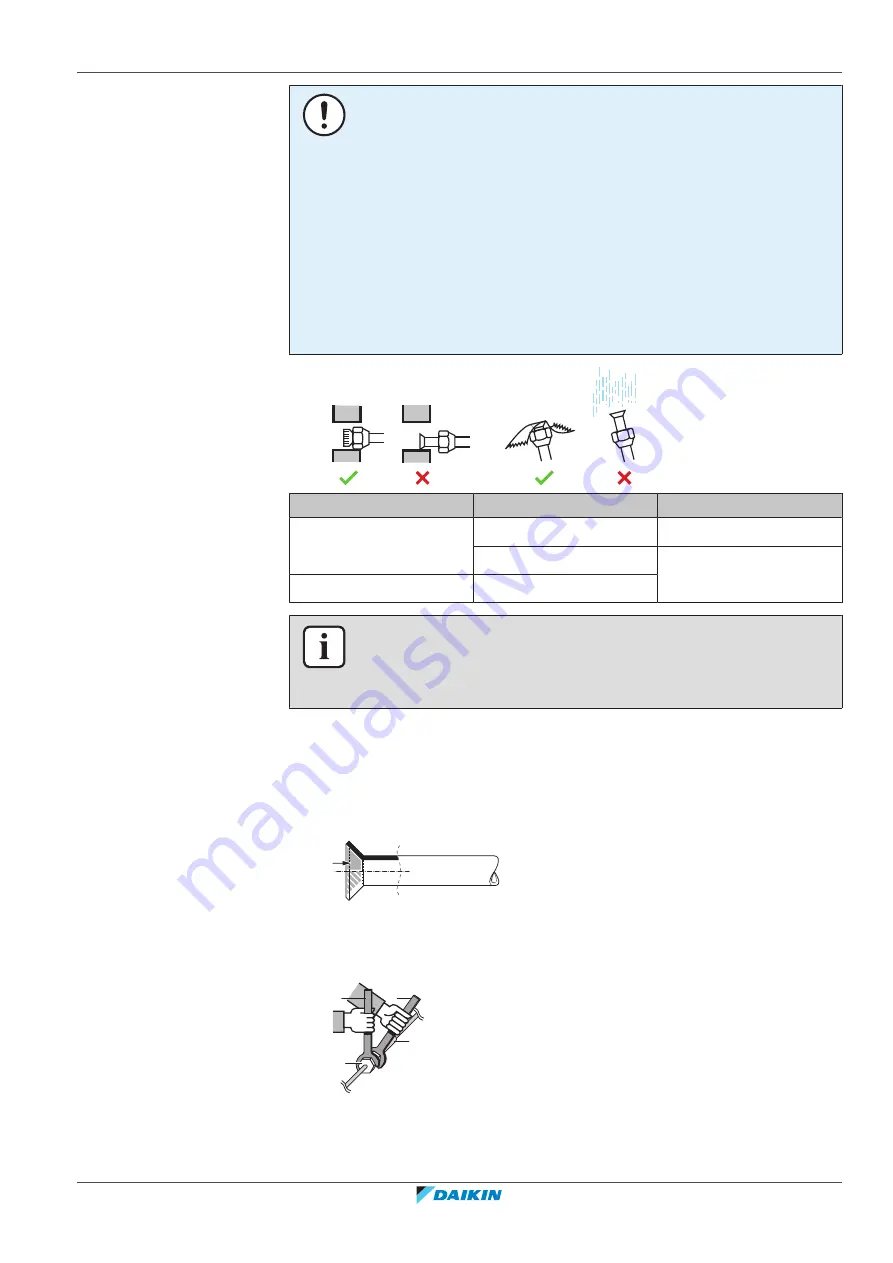

Protect the piping as described in the following table to prevent dirt, liquid or

dust from entering the piping.

▪

Use caution when passing copper tubes through walls (see figure below).

Unit

Installation period

Protection method

Outdoor unit

>1 month

Pinch the pipe

<1 month

Pinch or tape the pipe

Indoor unit

Regardless of the period

INFORMATION

Do NOT open the refrigerant stop valve before checking the refrigerant piping. When

you need to charge additional refrigerant it is recommended to open the refrigerant

stop valve after charging.

8.3.3 Guidelines when connecting the refrigerant piping

Take the following guidelines into account when connecting pipes:

▪

Coat the flare inner surface with ether oil or ester oil when connecting a flare

nut. Tighten 3 or 4 turns by hand, before tightening firmly.

▪

ALWAYS use 2 wrenches together when loosening a flare nut.

▪

ALWAYS use a spanner and torque wrench together to tighten the flare nut when

connecting the piping. This to prevent nut cracking and leaks.

a

b

c

d

a

Torque wrench

b

Spanner

c

Piping union

d

Flare nut