INSTRUCTION MANUAL DAAB AUTOMATIC CONTROLL UNIT EP104 4.08

12

Instruction manual edition 1 for EP104 version 4.08

Connections

• Safety

!

The electrical connections may only be made by a qualified electrician, who accepts responsibility for ensuring that the

electric connections have been carried out in accordance with the applicable standards and this instruction manual.

Always disconnect the power supply when connecting the control box.

Mechanical installation of the control unit must be carried out by persons with the necessary knowledge for the task.

• Installation

The location of the control unit must be selected with regard to the protection class of the enclosure, at least IP54. A

heating and/or cooling element should be included if necessary to maintain the operating temperature stated in the technical

specification.

The control unit must be securely fixed to a wall or a bracket intended for this purpose, using screw joints. The fixing holes

are on the rear or underside of the enclosure.

Cables into and out of the enclosure must have cable entry seals that are approved for use with the particular cable. Cables

outside the enclosure must be securely fixed to the surrounding structure. They must not hang loose and there must be no

possibility of them catching on passing objects.

• High current

The power supply must be connected via a lockable main switch, and have T10A protection.

Connect the incoming earth to the earth bar.

Check that the power supply and motor voltage are compatible.

Motors

The largest motor that can be connected is 1.5 kW (3-phase 3x400 V).

See "Commissioning" for details of how to check the direction of rotation.

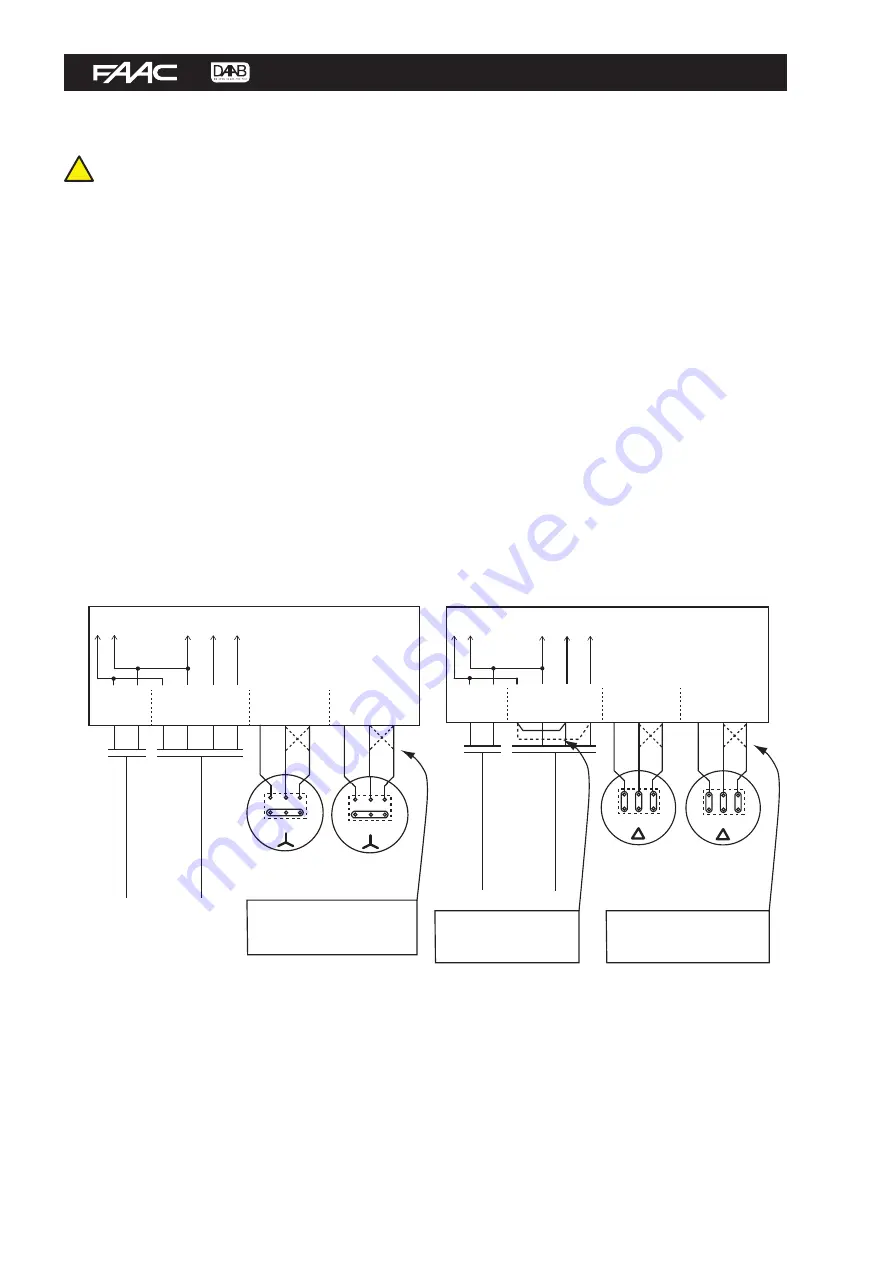

Connecting motors to the EP104

Supply 3x400V with neutral

N T1 N L1 L2 L3 U1 V1 W1

U2 V2 W2

O

ut

let

230V

3x400V

+

N

Fus

e max T10A

U1

V1

W1

W2

U2

V2

U1

V1

W1

W2

U2

V2

Supply to control board

Supply motors

EP104

In/Out

Power

Motor 1

Motor 2

Switch V1 and W1 and/

or V2 and W2 if the motor

runs in the wrong direction.

3-phase motor

Y-connected

3-phase motor

Y-connected

Supply 3x230V without neutral

O

ut

let

230V

3x230V

Fus

e max T

10A

U1

V1

W1

W2

U2

V2

U1

V1

W1

W2

U2

V2

N T1 N L1 L2 L3 U1 V1 W1

U2 V2 W2

EP104

In/Out

Power

Motor 1

Motor 2

Supply to control board

Supply to motors

3-phase motor

D-connected

3-phase motor

D-connected

Change of phase

sequence if the load

guard value shows fault.

Switch V1 and W1 and/

or V2 and W2 if the motor

runs in the wrong direction.

Summary of Contents for EP104

Page 60: ......