Civemasa Implementos Agrícolas

26

CRO 4.0

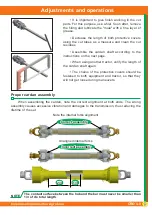

Adjustments and operations

Operations - Important points

• Retighten nuts and bolts after the first day of service. Check the conditions of

all pins and cotter pins. Then, retighten every 24 service hours;

• Check if the composting plant is leveled and compacted;

• The plant must have a declivity to facilitate the outflow of surface water;

• To use the equipment, the tractor must have a PTO with

540 RPM

, hydraulic

system quick coupler type. Minimum power of

80 - 120 CV

and creeper gear to

reach a speed of

200 - 320 meters/hour;

• The tractor motor acceleration must correspond to

540 RPM

on the PTO; do not

overpass this speed;

• The working speed must variate from

200 to 320 meters/hour;

• On the beginning/end of the grooves, there must have enough space to maneuver

the equipment;

• Regularly check the tightening of the fixation bolts on the rotor fins. Avoid to work

with loose fins or crooked ones, as they may unbalance the rotor;

• Note the lubrication intervals carefully. (See 'lubrication' section for instructions);

• Regularly check the tractor hydraulic system;

• The oil level on the gearbox must be checked weekly and filled up when necessary

with

SAE 90

mineral oil;

• Grooves dimension:

4 meters wide x 1.50 meters high

;

• The equipment tires must be calibrated according to the instructions on the 'tires

inflation' page;

• The calibration must always be done with a contention device (tire inflation cage);

• During working or transportation, do not allow the presence of passengers on

the tractor or equipment.

• Remove pieces of wood or any object that may get stuck to the equipment;

• For testing or activating the rotor, be careful if there are any people close to the

operation, on a risky condition;

• As previously mentioned, the CRO compost turner has several adjustments.

However, only the local conditions can determine its best adjustment.

NOTE The groove dimensions described above are for working with filter cake. When

working with another material that has another density, these dimensions

have to be re-defined, so the equipment can work normally with such material.