Civemasa Implementos Agrícolas

25

CRO 4.0

PROBLEM

CAUSES

POSSIBLE SOLUTIONS

Quick couplers

are not adapting. Different type of couplers.

Have the same type of male and female

couplers.

Leaking hoses

w i t h f i x e d

terminals.

Insufficient tightening.

Retighten carefully.

Lack of sealing material on the

thread.

Use thread sealing tape and retighten

carefully.

H y d r a u l i c

cylinder leaking.

Damaged repairs.

Replace the repairs.

Damaged rod.

Replace the rod.

Oil with impurities.

Replace oil, repairs and filters.

Working pressure higher

than recommended.

Adjust the command through the relief

valve with the help of a gauge.

Normal pressure: 180 Kgf/cm

2.

Hydraulic oil temperature

excess.

Check the oil level on the tractor.

Quick couplers

leaking.

Insufficient tightening.

Retighten carefully.

Lack of sealing material on the

thread.

Use thread sealing tape and retighten

carefully.

Damaged repairs.

Replace the repairs.

Tractor stalling. Over-sized groove.

Reduce the size of the groove.

Clutch slippery

excess.

Lack of tightening on the clutch

bolts.

Check the bolts tightening according to

the manual.

Retighten the bolts.

Worn out rotor

fins.

Sandy compost.

Wheel working too close from

the soil.

Reposition the rotor through the height

adjustment (lateral tire) or junction pin

(Rotor/tow).

Troubleshooting guide

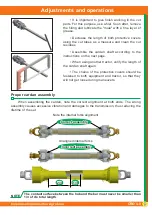

Adjustments and operations