4

SECTION II

• SPECIFICATIONS

TABLE A – QUALIFIED SYSTEM PERFORMANCE

Because the performance of an RO Membrane is highly dependent upon pressure, temperature, pH and TDS, the following

should be used for comparison purposes only.

U.S.

Metric

Membrane Production

1

41-53 gpd

155-201 lpd

Membrane TDS Reduction

1

96% minimum

96% minimum

Drain (reject water) Flow

3-5 times product flow

3-5 times product flow

Empty Storage Tank Pre-charge

5-7 psig air

35-48kPa air

1: Industry standards measure RO Membranes performance with no backpressure on the product water, at 65 psig (448kPa)

and 77°F (25°C). Further conditions on the above are 600 ppm TDS. Production rate and TDS reduction figures are for a

new Membrane that has been rinsed for 24 hours. The production rate of a new Membrane can decrease by 10% per year

or more, depending upon the scaling and fouling tendencies of the Feed Water.

TABLE B – RECOMMENDED OPERATING LIMITS FOR FEED WATER

U.S.

Metric

Water Pressure

40 -100 psig

280 - 690 kPa

TDS

2000 ppm max.

2000 mg/l max.

Temperature

40-100°F

4-38°C

pH

4-11 (optimum rejection at pH 7.0-7.5)

Hardness

<10 g/g or soften

<170 mg/l or soften

Iron

<0.1 ppm

<0.1 mg/l

Manganese

<0.05 ppm

<0.05 mg/l

Hydrogen Sulfide

None

None

Chlorine

Chlorine will damage a TFC Membrane. The Sediment/Carbon Module has

been designed to reduce chlorine from the incoming water. Change filter every

6 to 12 months, more often if the water contains more than 1 ppm chlorine.

Bacteria

Must be potable. DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY

UNSAFE OR OF UNKNOWN QUALITY, WITHOUT ADEQUATE DISINFECTION

BEFORE THE SYSTEM.

Summary of Contents for CWQC50

Page 1: ...INSTALLATION OPERATION AND SERVICE MANUAL RO DRINKING WATER SYSTEM MODEL CWQC50...

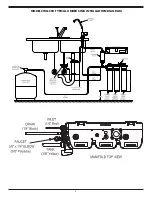

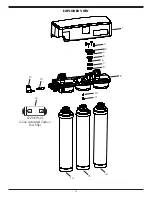

Page 5: ...5 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

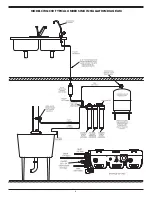

Page 6: ...6 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

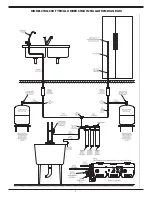

Page 7: ...7 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...