9

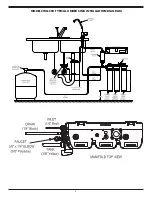

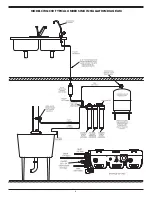

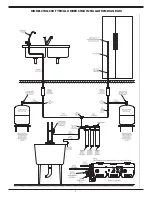

2. Drinking Water Holding Tank

The Holding Tank may be placed where it is convenient within 10 feet of the faucet; under the sink or in an adjacent cabinet

are the best choices. If a longer run of tubing is required, the tubing should be the 3/8" diameter OD size to prevent a high

pressure drop. Remember, these tanks can weigh up to 30 pounds when full of water; a firm, level area is required.

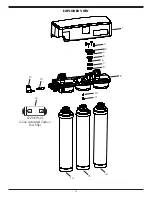

3. RO Manifold Assembly

The manifold can be installed on either the right or left side of the under–sink area or a cabinet. The right side is

recommended because all the tubing will be to the back of the cabinet and out of the way. Installation in the basement is

also an option. Another location is near the laundry/utility sink where cold potable water and drain access is handy. The

mounting location should allow adequate clearance and accessibility for cartridge changes.

4. Feed Water Connection

The Feed Water Saddle Valve should be located as close to the manifold assembly as possible. USE A POTABLE COLD

WATER SUPPLY ONLY. Softened water is preferred as it will extend the life of the RO Membrane.

5. Drain Connection

The wastewater must go to drain through an anti–siphon air gap. The air gap is provided in the base of the faucet. If

discharging into a utility sink or standpipe, an air gap of greater than 1" above the flood rim must be provided. Do NOT

connect the system drain line to the dishwasher drain or near the garbage disposal. Backpressure from these units may

cause the air gap to overflow.

SECTION IV

• INSTALLATION STEPS

All plumbing should be done in accordance with state and local plumbing codes.

NOTE: Some codes may require installation by a licensed plumber; check with the local plumbing authority prior to

installation.

In restricted under–sink areas, it may be easier to install the faucet first. Allow adequate tubing lengths for any final

component position.

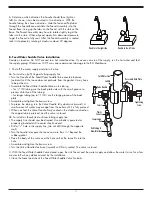

A. Faucet Installation

The faucet contains an anti–siphon air gap. While the system is producing water, the drain water flows from the RO, through

the air gap and then to the household drain. The purpose of the air gap is to prevent water in the drain from backing up into

the RO Drinking Water System.

The easiest installation is to use an existing spray attachment hole. If the spray faucet hole is not available, then the sink top

must be drilled.

1. Mark the location of the center of the faucet base

2a. Drilling a stainless-steel sink:

• Center punch the hole to provide a starting point for the drill.

• Start with a smaller drill as a pilot, and then drill a ½" diameter hole to accept the bolt of a 1¼" Greenlee Hole Punch

(1¼" chassis punch).

• Clean away any chips.

• Install the punch and tighten the nut to cut the hole.

• Deburr any sharp edges.

2b. Drilling a porcelain sink:

It is best to use a special 1¼" diameter cutter designed for porcelain. A carbide tipped masonry bit is a second choice.

• Place a piece of tape over the area to be drilled to help prevent chipping.

• Drill a pilot hole for the porcelain cutter. Use the pilot drill supplied with the kit or a carbide tipped drill.

• When drilling the 1¼" hole, drill slowly and carefully; the porcelain chips easily.

• After drilling, clean the area well. Iron filings, if left in place, can cause rust stains.

2c. Drilling a countertop:

NOTE: The countertop must be less than 1¼" thick. Treat ceramic tile as porcelain until the tile is penetrated, then use the

carbide tipped metal cutter. Formica counter tops may be drilled with a good 1¼" wood bit; drilling a

3

⁄

32

" pilot hole will

help keep the bit going straight.

Summary of Contents for CWQC50

Page 1: ...INSTALLATION OPERATION AND SERVICE MANUAL RO DRINKING WATER SYSTEM MODEL CWQC50...

Page 5: ...5 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

Page 6: ...6 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

Page 7: ...7 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...