8

SECTION III

• PREPARATION

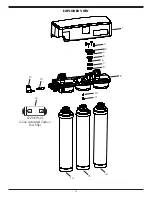

A. Major System Components

The following components comprise the R.O. Drinking Water System.

• An RO Manifold assembly.

• A Drinking Water Holding Tank.

• A Dispensing Faucet.

• A Feed Water Saddle Valve.

• A Drain Clamp.

• Plastic Tubing and tube connectors.

• A Reverse Osmosis Membrane Module.

• Two Sediment/Carbon Modules.

• RO System Cover

• Other items necessary for installation may include wood screws or machine screws and nuts for mounting the manifold,

or concrete anchors for hanging on basement wall. Additional tubing or tube connectors. Plastic wire ties for organizing

tubing.

B. Tools Recommended for Installation

The following tools will cover most of the installation sites encountered:

•

3

⁄

8

" variable speed electric drill.

• Extension work light with outlet.

• Safety glasses.

• 1¼" porcelain hole cutter kit.

• 1¼" Greenlee hole punch and

1

⁄

8

" and ½" metal drill bits for pilot hole.

• Center punch and hammer.

• 1¼" wood bit.

• Concrete drill bits.

• Assorted wood and metal drill bits including

7

⁄

32

" metal drill bit.

• Phillips head and flat blade screwdrivers.

• ½",

9

⁄

16

" and

5

⁄

8

" open end wrenches.

• Teflon tape.

• Wide masking tape or duct tape.

• Plastic tubing cutter.

• Extra plastic tubing.

• Low range air pressure gauge.

• Bicycle hand air pump or compressor.

• Small bottle of liquid chlorine bleach.

• Graduated measuring cylinder.

• Paper towels, whisk broom and assorted clean up materials.

C. Site Selection for Major System Components

The RO System is designed to fit under a sink, however, because of space limitations or other reasons, the system’s flexible

design allows for installation in other locations. When determining the location, remember that access to a cold water tap

line, the household drain, and ease of filter replacement are important considerations. All components and tubing should

be located in an area which is not exposed to freezing temperatures. If winter temperatures are severe, the area should be

above the minimum temperature listed in Table B for proper performance. Do not expose unit or tubing to direct sunlight.

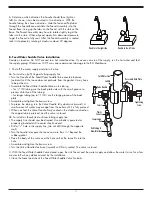

1. Dispensing Faucet

The faucet should be placed near the sink where drinking water is normally obtained. Convenience of use (filling of water

pitchers and glasses), and an open area beneath the faucet under the sink for attaching product and drain tubing are

considerations. A 2" diameter flat surface is required above and below the installation site. The thickness of the mounting

surface should not exceed 1¼". Watch for strengthening webbing on the underside of cast iron sinks.

Summary of Contents for CWQC50

Page 1: ...INSTALLATION OPERATION AND SERVICE MANUAL RO DRINKING WATER SYSTEM MODEL CWQC50...

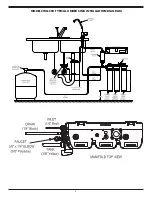

Page 5: ...5 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

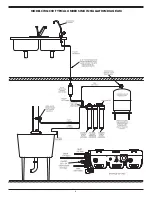

Page 6: ...6 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...

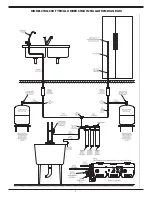

Page 7: ...7 MODEL CWQC50 TYPICAL UNDER SINK INSTALLATION DIAGRAM...