WARNING!

Do not interfere with this system in any way, do not press the spindle

manually - only the handle is for "system operation"

3.

System of immediate boiler shutdown when the ash tank is removed (WO,

WZO)

This system works in the same way as with the door handle. Lifting the ash container handle opens

the limit switch and turns off the boiler .

Figure 34 - Protection of the ash container

4.

Burner temperature sensor - Details in the burner manual

5.

Motor verification of the external feeder reducer by the algorithm of the

controller and the hardware of the controller

6.

Exhaust backflow

The boiler is secured with a spiro pipe between the burner and the feeder. In the event of flashback

in the burner, the pipe will burn. As a result, fuel will no longer be given to the burner.

8.2 Procedure in the event of a failure

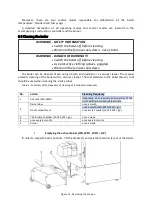

Table XI - List of common faults

No.

Fault

The cause of the fault

How to remove the fault

1.

The burner does not

ignite

Message:

"Failed

firing

attempt"

No fuel in the container

Refill the fuel in the container

Perform the auger filling procedure -

point 6.2

Clear the error by pressing the knob

Blockade of fuel feeding augers

Remove the locking element

Defective igniter

Contact the manufacturer's service point

Damage of the drives of the

feeding augers

Contact the manufacturer's service point

Slag in the furnace

Clean the combustion chamber

Photodiode damaged or dirty

Clean the photo diode

In the event of damage, contact the

manufacturer's service point

Slag or ashes in the furnace

chamber of the central heating

boiler at the level of the burner

combustion chamber

Clean the furnace of the central heating

boiler.

2.

Alarm:

Excessive temperature rise of

the housing caused withdrawal

of the burner flame from the

The controller will automatically switch to

the furnace putting out mode. The alarm

can only be cleared by the user.

Summary of Contents for QUAD 10

Page 11: ......