7 Inspection, service activities and maintenance recommendations

Service inspection recommended once a year by the installer / authorized boiler or burner

service . The scope of service activities includes:

Burner cleaning ,

Verification for condensation and tightness ,

Boiler gas tightness verification .

In order to ensure trouble-free operation, as well as to extend the life of the boiler, follow the

recommendations below:

The furnace should be kept clean - by cleaning it regularly. The frequency of

this treatment depends on the quality of the fuel, its ash content and humidity, as

well as the frequency of burner activation, the size of the CH boiler furnace chamber

and the size of the ash pan. On average, it should take place once a week.

Detailed instructions for cleaning the burner are included in the attached burner manual.

Use only fuels recommended by the manufacturer.

It is forbidden to burn materials not intended for this purpose.

Adequate fresh air must be provided.

8 Security systems

The hazards and safety assessment of the device were carried out in the risk assessment. This

information has been archived in the technical documentation of the device at the manufacturer's.

8.1 Safety systems in the boiler

1.

Protective mesh in the container ( WZ, WZO, WZ + gp , WZO + gp )

The fuel tank in the boiler is equipped with a protective mesh. It protects against the risk

of putting your hand in the pellet feeding spiral in the feeder. The grid is illustrated in Figure 6 .

2.

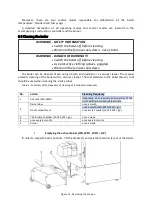

System of immediate boiler shutdown when the door is opened

To prevent the risk of the user coming into contact with the flame, a boiler switch-off system was

installed at the door handle. Opening the door handle turns the boiler off.

Figure 33 - Security of the door handle

Summary of Contents for QUAD 10

Page 11: ......