Instructions for Proper Maintenance

Your Cedar Summit Play System is designed and constructed of quality materials with your child’s safety in mind. As with all

outdoor products used by children, it will weather and wear. To maximize the enjoyment, safety and life of your Play Set, it is

important that you, the owner, properly maintain it.

HARDWARE:

Check metal parts for rust. If found,

sand and repaint using a non-lead

paint complying with 16 CFR 1303.

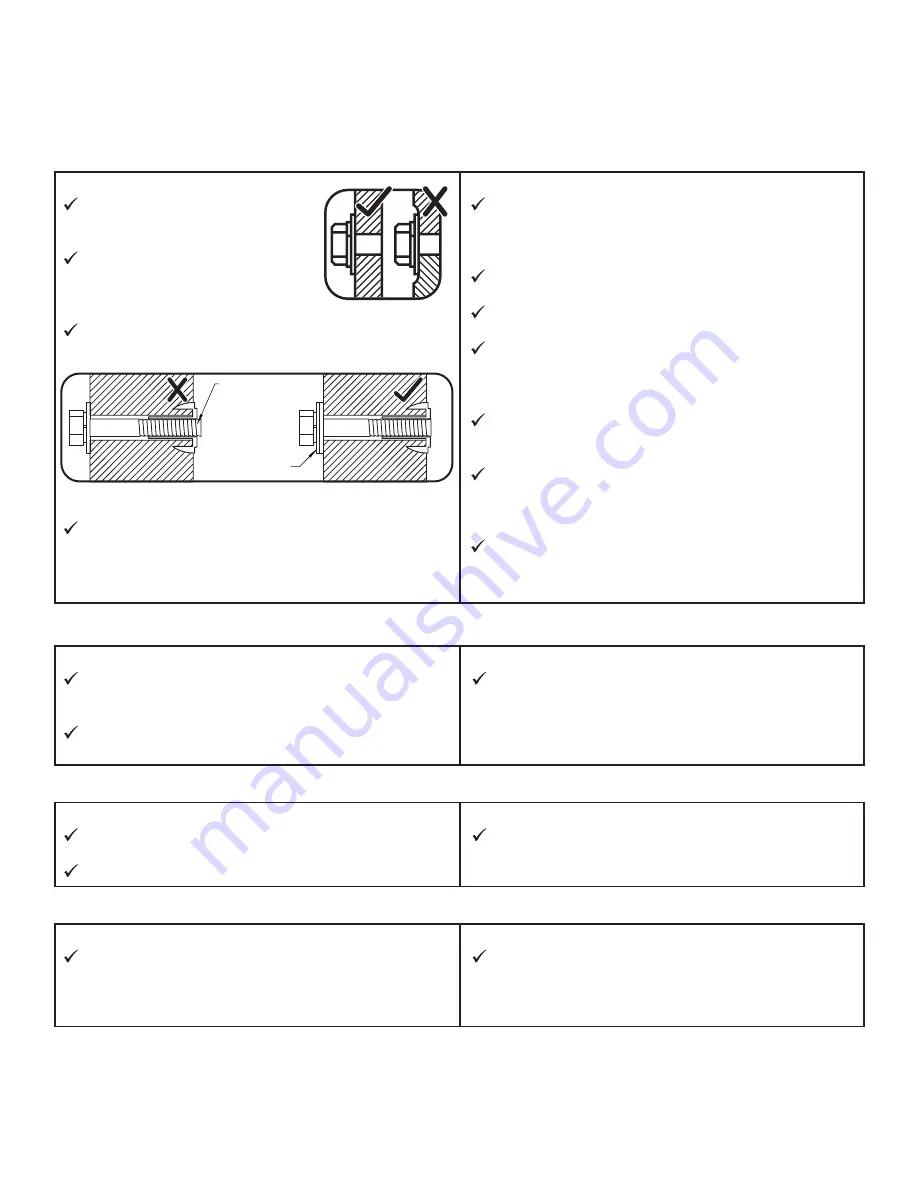

Inspect and tighten all hardware. On

wood assemblies DO NOT OVER-

TIGHTEN as to cause crushing and

splintering of wood.

Check for sharp edges or protruding screw threads, add

washers if required.

SHOCK ABSORBING SURFACING:

Check for foreign objects. Rake and check depth of loose

fill protective surfacing materials to prevent compaction

and maintain appropriate depth. Replace as necessary.

(See Protective Surfacing, page 3)

GROUND STAKES (ANCHORS):

Check for looseness, damage or deterioration. Should

firmly anchor unit to ground during use. Re-secure and

or replace, if necessary.

SWING HANGERS:

Check that bolts are secure and tight. Quick clips should

be completely closed and threaded clips screwed tight.

If squeaking occurs lubricate bushings with oil or WD-40®.

SWINGS, ROPES AND RIDES:

Reinstall if removed during cold season. Check all

moving parts including swing seats, ropes, chains and

attachments for wear, rust and other deterioration.

Replace as needed.

Check that ropes are tight, secure at both ends and

cannot loop back as to create an entrapment.

WOOD PARTS:

Check all wood members for deterioration, structural

damage and splintering. Sand down splinters and replace

deteriorated wood members. As with all wood, some

checking and small cracks in grain is normal.

Unprotected, they will appear weathered over time.

Periodic application of an exterior water repellent or stain

(water-based) will help improve appearance and life.

Check the following at the beginning of the play season:

HARDWARE:

Inspect for tightness. Must be firmly against, but not

crushing the wood. DO NOT OVER-TIGHTEN.

This will cause splintering of wood.

Check for sharp edges or protruding screw threads.

Add washers if required.

SHOCK ABSORBING SURFACING:

Rake and check depth of loose fill protective surfacing

materials to prevent compaction and maintain appropriate

depth. Replace as necessary.

(See Protective Surfacing, page 3)

Check twice a month during play season:

SWING HANGERS:

Check that they are secure and orientated correctly. Hook

should rotate freely and perpendicular to support beam.

If squeaking occurs lubricate bushings with oil or WD-40®.

SWINGS AND RIDES:

Check swing seats, all ropes, chains and attachments for

fraying, wear, excessive corrosion or damage.

Replace if structurally damaged or deteriorated.

Check once a month during play season:

SWINGS AND RIDES:

To prolong their life, remove swings and store inside

when outside temperature is below 32°F/0°C. Below

freezing, plastic parts may become more brittle.

SHOCK ABSORBING SURFACING:

Rake and check depth of loose fill protective surfacing

materials to prevent compaction and maintain appropriate

depth. Replace as necessary.

(See Protective Surfacing, page 3)

Check at the end of the play season:

If you dispose of your play set:

Please disassemble and dispose of your unit so that it does not create any unreasonable hazards

at the time it is discarded. Be sure to follow your local waste ordinances.

4

Use an extra

Flat Washer

If Bolt protrudes

beyond T-Nut

4