44

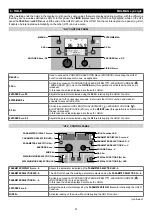

“HT4” CONTROL PANEL

WELDING MODE SELECTION LED

WELDING MODE SELECTION K

EY

WIRE K

EY

ENCODER K

NOB

- A

PARAMETER SELECTION K

EY

- A

PARAMETER SELECTION LED - A

PARAMETER DISPLAY S

CREEN

- A

SPECIAL FUNCTIONS (F

X

) LED

SPECIAL FUNCTIONS (F

X

) K

EY

GAS K

EY

ENCODER K

NOB

- V

PARAMETER SELECTION K

EY

- V

PARAMETER SELECTION LED - V

PARAMETER DISPLAY S

CREEN

- V

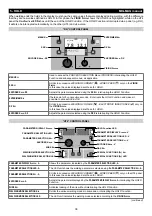

HOLD Function LED

PARAMETER DISPLAY S

CREEN

- A

Displays the value of the parameter

WELDING CURRENT

( ).

PARAMETER SELECTION LED - A

The LED unit shows the

WELDING CURRENT

( ) switched on.

ENCODER K

NOB

- A

Adjusts the

WELDING CURRENT

( ) parameter, interrupting the

HOLD Function

.

HOLD F

UNCTION

LED

Flashes for a set time, informing the operator that the

HOLD Function

is active.

PARAMETER DISPLAY S

CREEN

- V

Shows the parameter indicated by the

PARAMETER SELECTION LED - V

.

PARAMETER SELECTION LED - V

The LED unit indicates the welding parameter selected using the

PARAMETER SELECTION K

EY

- V

.

PARAMETER SELECTION K

EY

- V

Scrolls in succession the parameters

HOT START

( ) -

WELDING VOLTAGE

( ) -

ARC

FORCE

(

) only on the HT4 panel.

In this case the values displayed are those for

HOLD

(only for the welding voltage).

ENCODER K

NOB

- V

Adjusts the parameter displayed by the

PARAMETER DISPLAY S

CREEN

- V

interrupting the

HOLD

Function

.

SPECIAL FUNCTIONS (F

X

) K

EY

Only enables entering, interrupting the

HOLD Function

and exit afterwards from the

SPECIAL FUNCTIONS Menu (SET UP Fx)

on the HT4 panel and not on the DH panel.

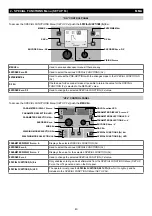

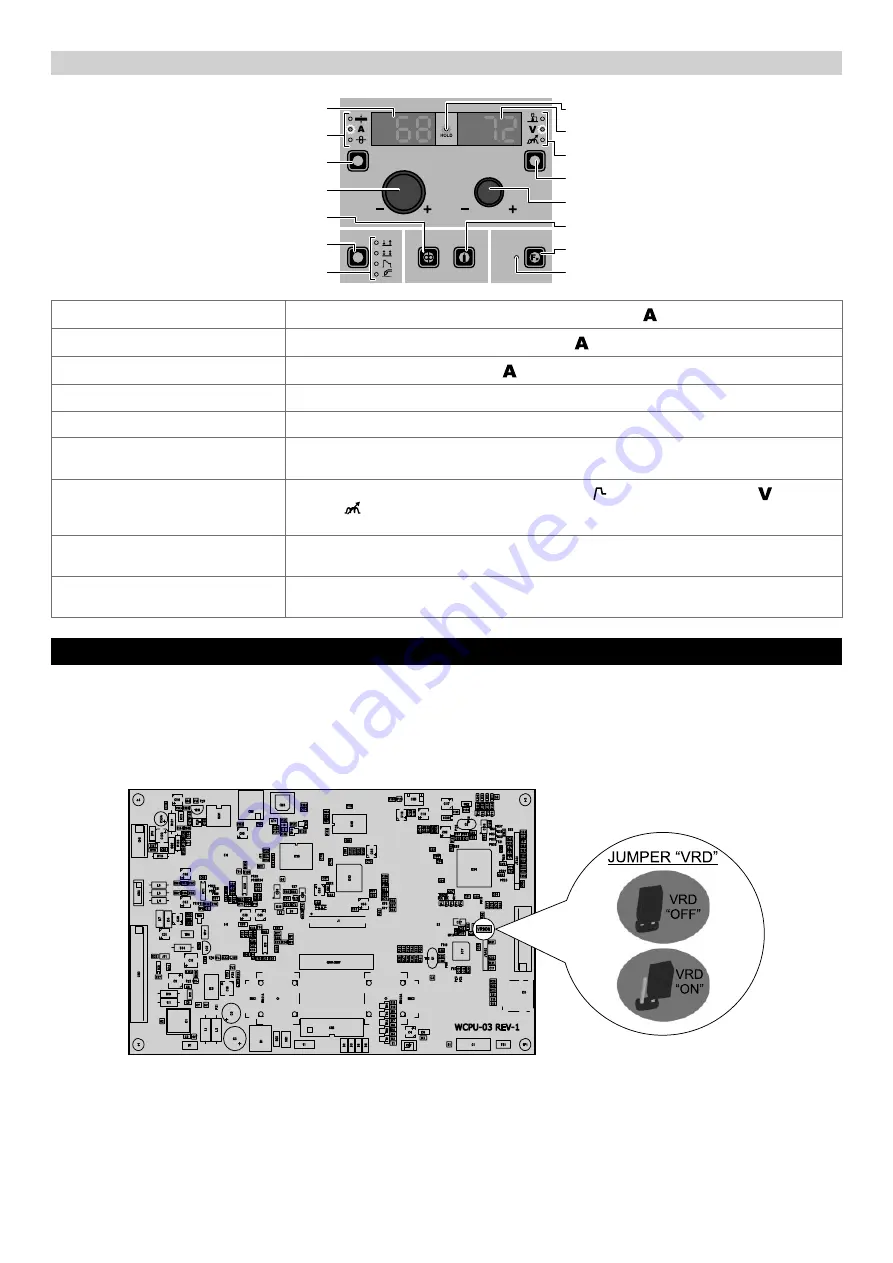

6 - ACTIVATING THE VRD DEVICE

MMA

The Voltage Reduction Device (VRD) is a safety device that reduces voltage. It prevents voltages forming on the output termi-

nals that may pose a danger to people. The standard settings and those defined beforehand by do not provide for the VRD to be

active on the welding machine and so the

VISION S

CREEN

does not normally provide any indication.

If the operator wishes to weld in MMA using the VRD device (which must be done with the welding machine switched off), they must:

1) Use a suitable screwdriver to unscrew the 4 screws that fix the DH control panel to the welding machine.

2) Remove the “VRD” JUMPER on the DIGITAL INTERFACE PCB (see figure).

3) Use a suitable screwdriver to tighten the 4 screws that fix the DH control panel to the welding machine.

4) Start the welding machine by turning the switch on the rear panel to position I.

When it switches on, but with the machine in stand-by, the DH control panel shows that the VRD device is active (indication on

the

VISION S

CREEN

green colour - see enclosed image: MMA - PRE-SETTING).

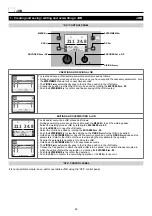

During the welding phase the VRD device is activated (indication on the

VISION S

CREEN

red colour (does not indicate malfunction-

ing of the welding machine) - see enclosed image: MMA - WELDING) and when welding is ended the voltage will be reduced

within a maximum time of

0,3

seconds.