6-21

T-294-01

RRS or SRS:

Using the plug connector marked “EC” that is

connected to the Controller module. Locate the wires

marked RRS or SRS, depending on which sensor needs

to be replaced. Follow that wire to the connector and

using the pins of the plug, measure the ohms resistance.

Readings are shown in Table 6-5.

6.23.2 Replacing Sensor (STS and SRS)

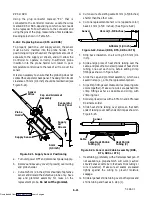

To properly position a unit supply sensor, the sensor

must be fully inserted into the probe holder. This

positioning will give the sensor the optimum amount of

exposure to the supply air stream, and will allow the

Controller to operate correctly. Insufficient probe

insertion into the probe holder will result in poor

temperature control due to the lack of air flow over the

sensor.

It is also necessary to ensure that the probe tip does not

contact the evaporator back panel. The design minimum

clearance of 6 mm (1/4 inch) should be maintained (see

Figure 6-21).

Cap and Grommet

Assembly

Probe

Holder

Supply Sensor

Sensor

Wires

Supply

Air

Stream

Evaporator

Back Panel

6 mm

(1/4 inch)

Figure 6-21. Supply Sensor Positioning

a. Turn unit power OFF and disconnect power supply.

b. Remove and save any cover (if present) over wiring

and probe holder.

c. Cut cable 5 cm (2 inches) from shoulder of defective

sensor and discard the defective probe only. Save

cap and grommet assembly for reuse on the

replacement probe.

Do not cut the grommet.

d. Cut one wire of existing cable 41 mm (1-5/8 inches)

shorter than the other wire.

e. Cut one replacement sensor wire (opposite color)

back 41 mm (1-5/8 inches). (See Figure 6-22.)

Sensor

41 mm (1-5/8 inches)

6.35 mm (1/4 inch)

Figure 6-22. Sensor (RRS, RTS, SRS or STS)

f. Strip back insulation on all wiring 6.35 mm (1/4

inch).

g. Slide a large piece of heat shrink tubing over the

cable, and place the two small pieces of heat shrink

tubing, one over each wire, before adding crimp

fittings as shown in Figure 6-23.

h. Slide the cap and grommet assembly, which was

saved in step (c.), onto the replacement sensor.

i. Slip crimp fittings over dressed wires (keeping wire

colors together). Make sure wires are pushed into

crimp fittings as far as possible and crimp with

crimping tool.

j. Solder spliced wires with a 60% tin and 40% lead

Rosincore solder.

k. Slide heat shrink tubing over splice so that both

ends of tubing cover both ends of crimp as shown in

Figure 6-23.

Sensor

Cable

Heat Shrink

Tubing (2)

Large Heat Shrink

Tubing (1)

Figure 6-23. Sensor and Cable Assembly (RRS,

RTS, SRS or STS)

l. Heat tubing, preferably with a flameless heat gun. If

not available, a propane torch will work

(caution

should be taken not to burn the heat shrink tubing or

wire insulation

). Make sure all seams are sealed

tightly against the wiring to prevent moisture

seepage.

m. Slide large heat shrink tubing over both splices and

shrink tubing and heat as in step (l.).

Downloaded from