6-32

T-294-01

Centrifugal pump

30 GPM at 35’ head

Pump

Suction

Pump

support

Tank

Fine mesh

screen

Return

Remove water

regulating

valve

Condenser

Globe

valves

Gas

vent

Close vent pipe

valve when pump

is running.

Priming

connection

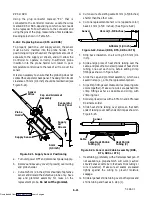

Figure 6-33. Water-Cooled Condenser Cleaning --

Forced Circulation

6. Allow the Oakite No. 32 solution to soak in the tube

coils

for

several

hours,

periodically

pump-circulating it with an acid-proof pump.

An alternate method may be used whereby a bottle (see

Figure 6-34) filled with the solution and attached to the

coils by a hose can serve the same purpose by raising

and lowering of the bottle. The solution must contact the

scale at every point for thorough de-scaling. Air pockets

in the solution should be avoided by regularly opening

the vent to release gas.

Keep flames away from the vent

gases.

7. The time required for de-scaling will vary,

depending upon the extent of the deposits. One way

to determine when de-scaling has been completed is

to titrate the solution periodically, using titrating

equipment provided free by the Oakite Technical

Service representative. As scale is being dissolved,

titrate readings will indicate that the Oakite No. 32

solution is losing strength. When the reading

remains constant for a reasonable time, this is an

indication that scale has been dissolved.

8. When de-scaling is complete, drain the solution and

flush thoroughly with water.

9. Following the water flush, circulate a 56.7 gram (2

ounce) per 3.785 liter (1 U.S. gallon) solution of

Oakite No. 22 thru the tubes to neutralize. Drain this

solution.

10.. Flush the tubes thoroughly with fresh water.

NOTE

If the condenser cooling water is not being used

as drinking water or is not re-circulated in a

closed or tower system, neutralizing is not

necessary.

11. Put the unit back in service and operate under

normal load. Check the head pressure. If normal, a

thorough de-scaling has been achieved.

What You Can Do For Further Help:

Contact the Engineering and Service Department of the

OAKITE PRODUCTS CO., 19 Rector Street, New

York, NY 10006 U.S.A. for the name and address of the

service representative in your area.

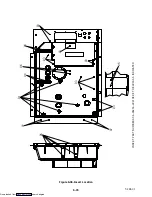

Fill condenser with

cleaning solution. Do

not add solution more

rapidly than vent can

exhaust gases caused

by chemical action.

Condenser

Vent

pipe

1” Pipe

5’ Approximate

3’ to 4’

Figure 6-34. Water-Cooled Condenser Cleaning --

Gravity Circulation

6.29 CONTROL BOX REPAIRS

6.29.1Introduction

This procedure provides instructions for repair of the

Carrier Transicold composite control box. Damage to

the control box may be in the form of a chip or hole, a

crack, a damaged thread insert or damage to the door

hinge inserts. Generally, the object of the repair must be

to ensure sufficient strength is restored to the damaged

area and the repair must keep the box water tight.

Information on repair kits and repair procedures for each

type of damage is provided in the following paragraphs.

Ambient temperature must be above 7

°

C (45

°

F) for

proper curing of epoxy repairs.

6.29.2 Cracks

Cracks in the control box are repaired using a fiberglass

patch over the damaged area. Materials required are

included in the Fiberglass Patch Kit supplied with Crack

Repair Kit, CTD part number 76-00724-00SV (see

Table 6-1 ).

Downloaded from