6-7

T-294-01

refrigerant container on weight scales. The correct

amount of refrigerant may be added by observing

the scales. (Refer to section 6.7)

6.7 REFRIGERANT CHARGE

6.7.1

Checking the Refrigerant Charge

NOTE

To avoid damage to the earth’s ozone layer, use

a refrigerant recovery system whenever

removing refrigerant. When working with

refrigerants you must comply with all local

government environmental laws. In the U.S.A.,

refer to EPA section 608.

NOTE

Set the controller set point to --25

_

C (--13

_

F) to

ensure that the suction modulation valve is

fully open when checking operation of unit.

The

container

temperature

should

be

approximately 1.7

_

C (35

_

F) or --17.8

_

C (0

_

F).

a. Connect the gauge manifold to line piercing valves,

refer to sections 6.2, 6.3 and 6.4.

b. Check charge only on air-cooled operation. Refer to

Figure 6-37 for charts on compressor pressure.

c. If the discharge/suction pressures are within the

normal operating system pressures, then the charge

should be correct.

d. If the discharge/suction pressures are NOT within

the normal operating system pressures, then refer to

sections 5.2, 5.3, 5.7 and 5.11 for possible causes. If

the unit is then determined to be low on refrigerant

charge, refer to section 6.7.2 or 6.7.3.

6.7.2

Adding Refrigerant to System (Full Charge)

a. Evacuate unit and leave in deep vacuum. (Refer to

section 6.6.)

b. Place cylinder of R-134a on scale and connect

charging line from cylinder to the liquid line

process tube. Purge charging line at liquid line and

then note weight of cylinder and refrigerant.

c. Open liquid valve on cylinder. Open liquid line

half-way and allow the liquid refrigerant to flow

into the unit until the correct weight of refrigerant

has been added as indicated by scales. Correct

charge is noted in Table 6-9.

NOTE

It may be necessary to finish charging the unit

through the suction line process tube in gas

form, due to pressure rise in high side of the

system. (Refer to section 6.7.3)

d. Backseat the manifold gauge port. Close liquid

valve on cylinder.

e. Start unit in cooling mode. Run approximately 10

minutes and check the refrigerant charge. (Refer to

section 6.7.1.)

6.7.3

Adding Refrigerant to System (Partial

Charge)

a. Examine the unit refrigerant system for any

evidence of leaks. Repair as necessary. (Refer to

section 6.5.)

b. Maintain the conditions outlined in section 6.7.1.

c. Fully backseat the manifold gauge port.

d. Connect charging line between the suction line

process tube and the cylinder of refrigerant R-134a.

Open VAPOR valve.

e. Partially frontseat (turn clockwise) the manifold

gauge valve and slowly add charge until the

refrigerant appears at the proper level (refer to

section 6.7.1).

6.7.4

Emergency

Shipboard

Refrigerant

Charging Procedure

If the unit is not maintaining set point, refer to sections

5.2, 5.7 and 5.11 for possible causes. If the unit is then

determined to be low on refrigerant charge, follow the

steps below.

a. Perform step 6.7.1.a.

b. If the unit is operating on water-cooled condenser

switch to air-cooled condenser operation, refer to

section 2.6.1.

c. If set point is in a perishable range, temporarily

lower the unit set point to ensure that the SMV is

fully open for this procedure.

CAUTION

Make sure supply air temperature does not

go below the original set point for more than

five minutes, or damage to the load may

occur.

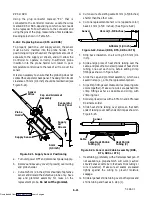

d. Refer to the pressure temperature curves in

Figure 6-37.

e. If the discharge/suction pressures are within the

normal operating system pressures, then the charge

should be correct.

Downloaded from