6-30

T-294-01

5. Press the ENTER key on the keypad.

6. The Display will show the message “Pro SoFt.”

This message will last for up to one minute.

7. The Display module will read:

(a.) When the software loading has successfully

completed: the Display will show the message

“Pro donE.”

(b.) If a problem occurs while loading the software:

the Display will blink the message “Pro FAIL”

or “bad 12V.” (Turn start-stop switch OFF and

remove the card.)

8. Turn unit OFF, via start-stop switch (ST).

9. Remove the programming card from the

programming/software port.

10. Turn unit ON, via start-stop switch (ST).

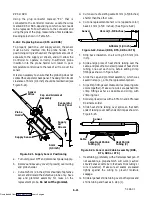

b. Procedure for loading Configuration Software

1. Turn unit OFF using start-stop switch (ST).

2. Insert the programming card, for Configuration

Software, into the programming/software port.

(See Figure 6-32.)

3. Turn unit ON using start-stop switch (ST).

4. The Display module will read:

(a.) If the correct card is being used, the digital

display will show “nt40” on the left LCD

display and “511XXX” on the right LCD

display. “XXX” will indicate the dash number

for a given unit model number, use the UP or

DOWN ARROW key to scroll through the list

to obtain the proper model dash number (i.e.,

For the unit 69NT40-511-201, the left display

will show “nt40,” press the UP or DOWN

ARROW key until the right display shows

“511201.”)

(b.) If a defective card is being used, the Display

will blink the message “bAd CArd.” (Turn

start-stop switch OFF and remove the card.)

5. Press the ENTER key on the keypad.

6. The Display module will read:

(a.) When the software loading has successfully

completed, the Display will show the message

“EEPrM donE.”

(b.) If a problem occurs while loading the software,

the Display will blink the message “Pro FAIL”

or “bad 12V.” Turn start-stop switch OFF and

remove the card.

7. Turn unit OFF using start-stop switch (ST).

8. Remove the programming card from the

programming/software port.

9. Turn unit ON using start-stop switch (ST).

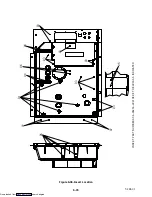

6.27.2 Controller Trouble-Shooting

A group of test points (tp) are provided on the Controller

(see Figure 6-32, item 3) for trouble-shooting electrical

circuits (refer to section 5). A description of the test

points follows:

NOTE

Use a digital voltmeter to measure ac voltage

between TP’s and ground (TP9), except for

TP8.

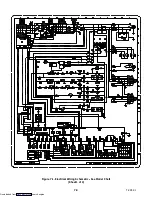

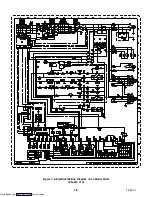

TP2

This test point enables the user to check if the internal

protector for the compressor motor (IP-CP) is open or

closed (and the Auto Transformer-IP if so equipped).

TP3

This test point enables the user to check if the optional

water pressure switch (WP) contact is open or closed.

TP 4

This test point enables the user to check if the internal

protector for the condenser fan motor (IP-CM) is open

or closed.

TP 5

This test point enables the user to check if the internal

protectors for the evaporator fan motor (IP-EM1 or

IP-EM2) is open or closed.

TP 9

This test point is the chassis (unit frame) ground

connection.

TP 10

This test point enables the user to check if the heat

termination thermostat (HTT) contact is open or closed.

Downloaded from