4-4

T-294-01

4.4.3

Cooling -- Controller Set BELOW --10

_

_

_

_

C

(+14

_

_

_

_

F), or --5

_

_

_

_

C (+23

_

_

_

_

F) optionally

NOTES

S

The stepper motor suction modulation valve

(SMV) may be up to 100% open depending

on the current and pressure limiting controls.

S

The evaporator motors run in low speed.

S

The compressor runs in high speed.

When the return air temperature decreases to 0.2

_

C

(0.4

_

F) below set point, relays TD and TN de-energize.

This results in de-energizing the compressor and

condenser fan motor. Also, the cool light is

de-energized. The evaporator fan motors continue to

run to circulate air throughout the container.

When the return air temperature increases to 0.2

_

C

(0.4

_

F) above set point, and providing a sufficient

off-time period has elapsed, relays TD and TN energize

to restart the compressor and condenser fan motor. Also

at this time, the cool light is illuminated.

4.4.4

Controller Set ABOVE --10

_

_

_

_

C (+14

_

_

_

_

F), or

--5

_

_

_

_

C (+23

_

_

_

_

F) optionally

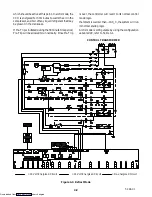

a. Cooling Mode (See Figure 4-1.)

NOTES

S

Evaporator fan motors will run in high speed.

(Contactor EF energized)

S

A pressure control system has been

incorporated by means of a condenser

pressure transducer (CPT) and condenser

pressure control (CPC) logic to maintain

discharge pressures above 130 psig in low

ambients.

S

The condenser fan will cycle off if the

condenser pressure is below 130 psig. If the

condenser pressure goes above 200 psig, the

condenser fan will cycle on.

With supply air temperature decreasing, and if the

supply air is above set point, the unit will be cooling

with the condenser fan motor, compressor motor and

evaporator fan motors energized. Also, at this time, the

cool light is illuminated.

When the air temperature decreases to a predetermined

tolerance above set point, relay TI energizes and the

in-range light is illuminated. (Refer to section 3.1.4,

Code 30.)

If the air temperature continues to fall, modulating

cooling starts at approximately 2.5

_

C (4.5

_

F) above set

point.

During this cooling mode, a running sum of the

temperature differential (supply air temperature -- set

point) is kept. When the supply air falls below set point,

the differential is negative. The longer supply air

remains below set point, the greater the negative

differential in the running sum.

When the supply air temperature decreases to 0.2

_

C or

more below set point and the running sum is greater than

or equal to --250 degrees Celsius seconds, relays TN and

TC de-energize shutting off the condenser fan and

compressor motors. Also, the cool light is de-energized.

NOTE

For example: If the temperature in the container

box falls 1

_

C below set point for 250 seconds,

or any combination of temperature and time

that equals 250 degrees Celsius seconds, the

unit will shut off. (Formula: X

_

C times TIME

in seconds. Where X is the amount of degrees in

Celsius, i.e., 1

_

C times 250 seconds = 250

degrees Celsius seconds.)

The evaporator fan motors continue to run to circulate

air throughout the container. The in-range light remains

illuminated as long as the supply air is within a tolerance

of set point, and the 15 minute override is met.

If the unit is in the holding mode (neither heating nor

cooling) and the supply air temperature increases to

0.2

_

C (0.4

_

F) above set point, and providing a six

minute off time has elapsed, relay TC energizes to

restart the compressor. Also, at this time, the condenser

fan motor starts and the cool light is illuminated.

Downloaded from