37

ENG

"humiFog direct" +0300073EN rel. 1.4 - 29.03.2022

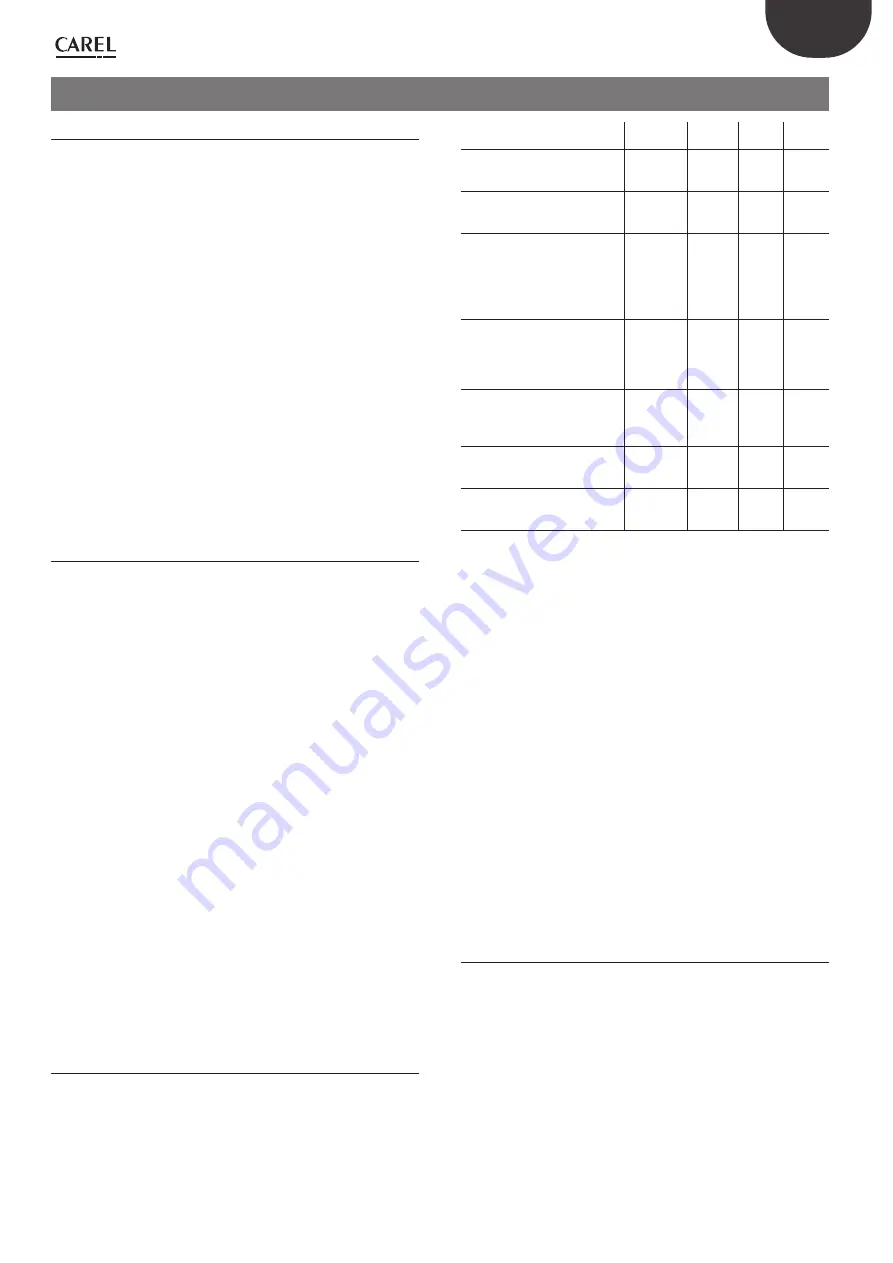

13. MAINTENANCE

Activity

Action if

necessary

Weekly

3

months

6

months

Visual verifi cation of the absence

of biofi lm, algae, deposits, excess

of atomised water

Cleaning

and restora-

tion

X

Odour-free verifi cation

Cleaning

and restora-

tion

X

Screening test for the determi-

nation of the number of colonies

by dip slides according to VDI

6022-1, permissible threshold <

100 CFU/ml (incubation at 30°C

from 48 to 72 h)

Cleaning

and restora-

tion

X

Qualifi ed sample (Legionella <

100 CFU/100 ml; Pseudomonas

aeruginosa < 100 CFU/100

ml; total CFU at 20°C and 36°C

respectively < 150 CFU/ml)

Cleaning

and restora-

tion

X

Check for deposits around the

nozzle orifi ce

Nozzle

cleaning or

replace-

ment

X

Exhaust test

Cleaning

and restora-

tion

X

Humidity probe function test

and limit probe intervention test

if present

Restoration

X

Tab. 13.a

If the threshold values in the table are exceeded, the frequency of the

activity should be halved until stable results below the prescribed

threshold are obtained. Conversely, if the threshold values are met for at

least one year, the inspection intervals can be adapted gradually.

The detection of biofi

lm in equipment is always evidence of

microbiological contamination and consequent risk to human health.

This outcome is critical and necessarily requires the following immediate

actions:

1.

shutting down the system;

2.

removal of biofi lm by means of an appropriate cleaning technique;

3.

microbiological testing of the surface and disinfection, where the

result of the microbiological testing indicates contamination;

4.

determination of the cause of biofi lm formation;

5.

long-term elimination of the identifi ed cause;

6.

if the cause cannot be eliminated, the humidifi cation system must be

taken out of service.

It is possible to use the thermal disinfection technique in advance by

bringing the water to 70°C (158°F) and keeping it in the system for at

least 3 minutes. Only after proven microbiological contamination are

disinfection techniques and listed chemical disinfectants permitted (see

Robert Koch Institute website). The eff ectiveness of alternative techniques

must be verifi ed and demonstrable. The success of the disinfection

operation must be proven by appropriate microbiological tests.

13.2 Routine maintenance

Routine maintenance is recommended every three months, and mainly

involves visual inspection of correct operation of the main components.

The following is a list of recommended operations:

•

Check water inlet fi lter.

It is recommended to change the fi lter cartridge once every 6-12 months.

To change the cartridge, switch the unit off and close the feedwater

line. Empty the fi lter using the small tap at the bottom. Empty the fi lter

container through the small tap at the bottom. Remove the fi lter cartridge

inside and fi t a new one (P/N ECKFILT050). Tighten the holder, ensuring

that the O-ring is still in good condition to ensure tightness. Close the tap

under the holder and open the feedwater line.

13.1 Hygienic aspects

Hygiene measures are essential for the safe operation of the humidifi cation

system in order to protect the occupants of the building from health

risks. In principle, the requirements for air humidifi cation according

to VDI 6022-1 must be observed. All tests and measurements shall be

documented in a logbook available for inspection. The user is responsible

for compliance with local regulations and applicable guidelines. Any risk

must be identifi ed, including during installation and maintenance, by the

Health and Safety Manager, whose role it is to introduce appropriate and

eff ective control measures.

WARNING: If improperly maintained, the humidifi cation system and the

reverse osmosis system could develop the growth of microorganisms in

the pipes, including the bacteria responsible for Legionella, which would

then be spread into the environment through the aerosol produced by

the atomising nozzles of the blower units. Contaminants can settle on

surfaces, be inhaled by people or be distributed by ventilation systems.

Comply with the inspection schedules listed under "Hygiene measures".

WARNING: Do not keep the humidifi cation system and reverse osmosis

system disconnected for more than 48 hours. Without a power supply,

the system is unable to perform automatic fl ushes. Keep the factory-set

automatic fl ushes enabled on both the reverse osmosis unit and the

humiFog direct system. If it is necessary to shut down the system for

more than 48 hours by disconnecting the power supply, the procedure

described in the section "Shutting down the system" must be followed.

13.1.1 Shutting down the system

Whenever the humidifi cation system is shut down for more than 48

hours, the following steps are required:

emptying;

cleaning;

drying;

washing before service is restored.

Emptying is automatic thanks to the normally open solenoid valves

which, in the absence of power supply or after 48 hours with power

supply present, allow drainage by gravity. Make sure that the slopes of

the high-pressure pipes are such as to favour the discharge through

the appropriate solenoid valves. Disconnect the high-pressure hoses

connected to the pumping station and the blower units, check that there

is no residual water in them and empty them if necessary. The expansion

tank or the storage tank interposed between the reverse osmosis system

and the demineralised water inlet to the pumping station must be

emptied by opening the appropriate manual valve (#8 in the "Functional

diagram" chapter). Drain the water fi lter (#12 in the "Functional diagram"

chapter) at the pumping station inlet.

Cleaning shall be carried out manually or by physical means on surfaces

in contact with water, e.g. by hot water or compressed air, but not

chemically. Chemical disinfection is only permitted following proven

microbiological contamination and must be conducted by qualifi ed

personnel in accordance with VDI 6022-6:2018-01 Chapter 9 and any

subsequent additions. In such cases, disinfectants that do not pose a

health risk and do not promote the development of resistance must be

used. The tubes should be dried with compressed air. When the power

supply is restored for humidifi cation system start-up, humiFog direct will

run an automatic washing and fi lling cycle if enabled (see paragraph

"Washing"; factory default: enabled with duration 4 minutes).

13.1.2 Hygiene

measures

Below is the list of preventive hygiene checks and the frequency with

which they must be carried out, as provided by VDI 6022-6 guidelines and

applicable to the humiFog direct system.

Summary of Contents for DLAQ2DF100

Page 1: ...NO POWER SIGNAL CABLES TOGETHER READ CAREFULLY IN THE TEXT humiFog direct User manual...

Page 2: ......

Page 4: ...4 ENG humiFog direct 0300073EN rel 1 4 29 03 2022...

Page 42: ...42 ENG humiFog direct 0300073EN rel 1 4 29 03 2022 14 2 Two zone wiring diagram GA1 Fig 14 b...

Page 46: ......

Page 47: ......