54

l

Can BREE

ZE

Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com

l

l

P. +90 216 484 2222

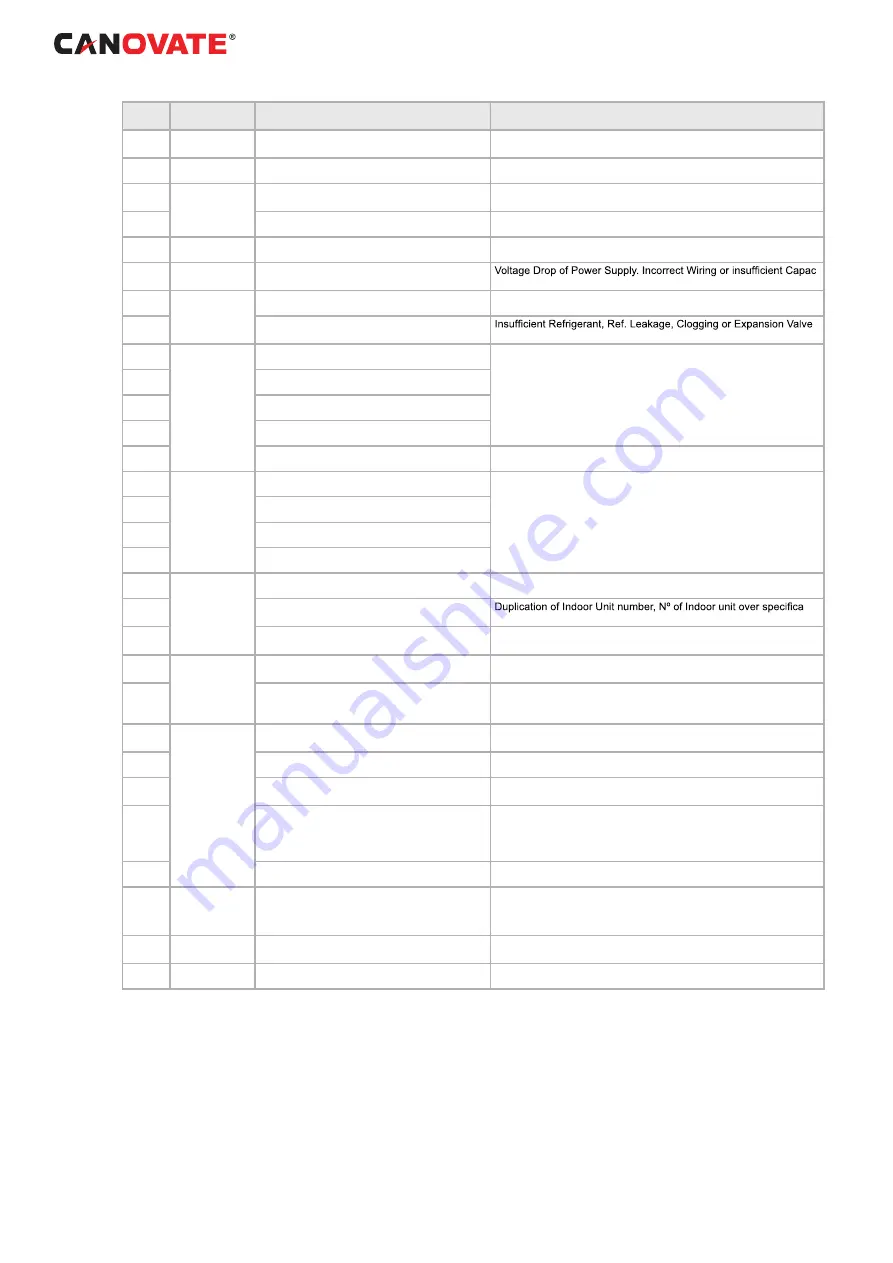

Code

No.

Category

Content of Abnormality

Leading Cause

01

Indoor Unit

Tripping of Protection Device

Failure of Fan Motor, Drain Discharge, PCB, Relay, Float Switch

Activated

02

Outdoor Unit

Tripping of Protection Device

Activation of PSH, Locked Motor

03

Transmission

Abnormality between Indoor (or Outdoor) and

Outdoor (or Indoor)

Incorrect Wiring, Failure of PCB, Tripping of Fuse, Power Supply

OFF

04

Abnormality between Inverter and Control PCB

Failure in Transmission between PCBs for Inverter

05

Power Supply

Abnormality power supply

Abnormal wave form of power supply.

06

Voltage Drop

Voltage Drop by Excessively Low or High Volt-

age to Outdoor Unit

-

ity of Power Supply Wiring

07

Cycle

Decrease in Discharge Gas Superheat

Excessive Refrigerant Charge, Expansion Valve Open Lock

08

Increase in Discharge Gas Temperature

Close Lock

11

Sensor on

Indoor Unit

Inlet Air Thermistor

Failure of Thermistor, Sensor, Connection.

12

Outlet Air Thermistor

13

Freeze Protection Thermistor

14

Gas Piping Thermistor

19

Tripping of Protection Device for Fan Motor

Failure of Fan Motor

20

Sensor on

Outdoor Unit

Compressor Thermistor

Failure of Thermistor, Sensor, Connection

(Incorrect Wiring, disconnecting wiring, breaking wire, short circuit)

21

High Pressure Sensor

22

Out+door Air Thermistor

24

Evaporating Thermistor

31

System

Incorrect Setting of Outdoor and Indoor Unit

Incorrect Setting of Capacity Code.

35

Incorrect Setting in Indoor Unit No.

-

tions.

38

Abnormality of Protective Circuit in Outdoor Unit

Failure of Indoor Unit PCB. Incorrect wiring. Connection to PCB in

Indoor Unit.

45

Pressure

Activation of High Pressure Increase Protection

Device

Overload Operation (Clogging, Short-Pass), Pipe Clogging, Exces-

sive Refrigerant, Inert Gas Mixing

47

Activation of Low Pressure Decrease Protection

Device

Stoppage by Excessively Decrease of evaporating Temperature

(Te < -35ºC) is activated 3 times in one hour, Locked Motor in Heat-

ing Operation.

48

Inverter

Activation of overload protection

Failure of IPM or PCB2, heat exchanger clogged, locked compres-

sor, EVI/EVO failure or overcharge.

51

Abnormality of Current Sensor for Inverter

Failure of Control PCB, Inverter Module.

53

Protection Activation of Transistor Module

Transistor Module Abnormality.

Failure of Compressor, clogging of Heat Exchanger.

54

Inverter Fin Temperature Increase

Abnormal Inverter Fin Thermistor.

Clogging of Heat Exchanger

Abnormal Outdoor Fan

55

Inverter Module Abnormality

Failure of Inverter Module.

57

Outdoor Fan

Fan Motor Abnormality

Disconnected wire of Incorrect wiring between Control PCB and

Inverter PCB.

Incorrect Wiring or Fan Motor Abnormality

b1

Indoor unit No.

setting

Incorrect address No. Setting or refrigerant

cycle

Over 64 indoor units setting by No. or indoor unit address.

EE

Compressor

Compressor protection alarm

Failure of compressor.