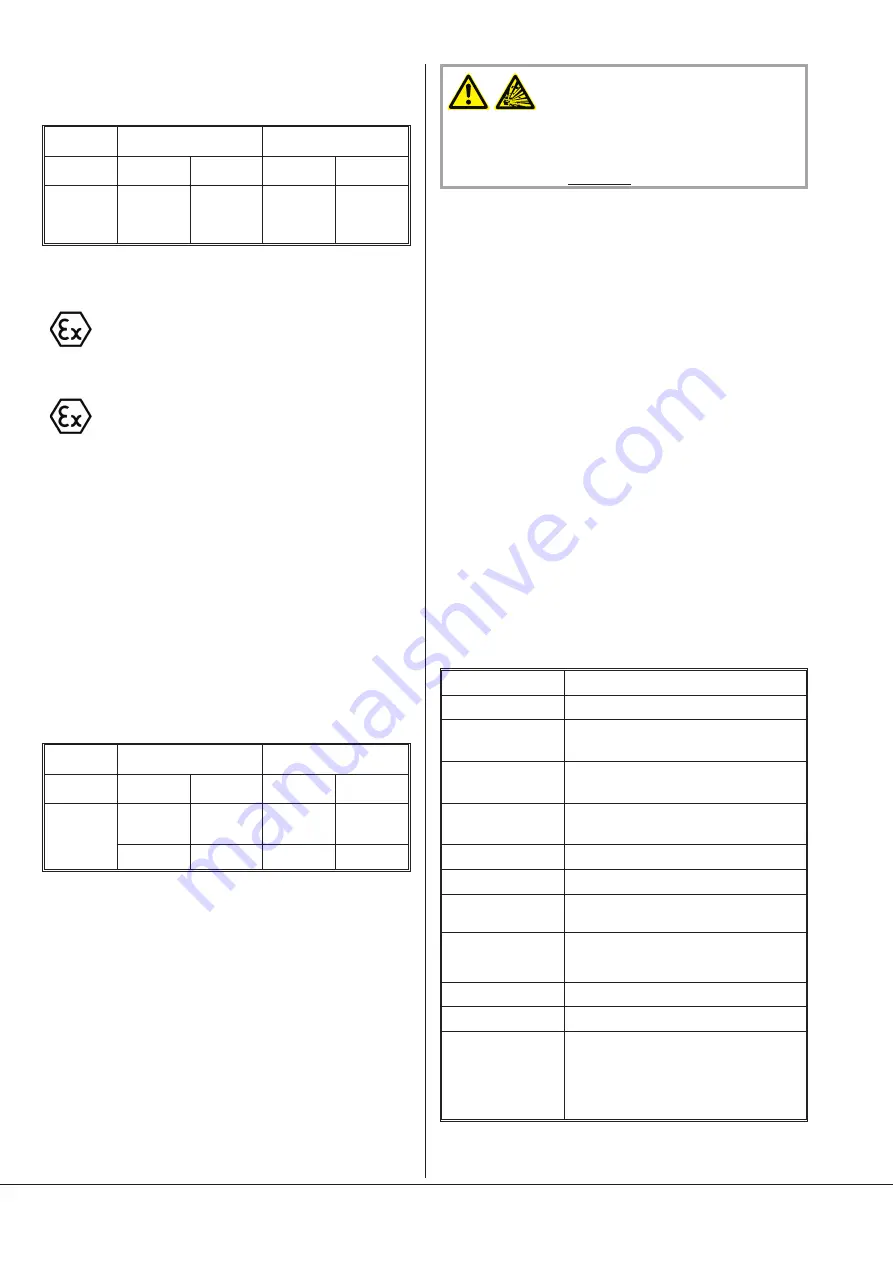

In the table below, you will find the possible alternative of temperature

classes depending of the cooling system and the maximal motor

frequency:

Cooling

system

Direct cooling

Recirculating cooling

Type

Temperature

class

Max. motor

frequency

Temperature

class

Max. motor

frequency

NC 0200 B

T4(i/o)

T3(i)/T4(o)

T3(i/o)

50 Hz

60 Hz

60 Hz

T3(i/o)

T3(i)/T4(o)

60 Hz

60 Hz

COBRA NC 0300 B

or

The following temperature classes are available

–

T4(i/o)

or

–

T3(i/o)

when the vacuum pump is equipped with a direct cooling system.

The

internal and external temperature class must be identical !

If the va-

cuum pump is equipped with a recirculating cooling system, only the

temperature class

T3(i/o)

is available.

For the adjustment of the temperature class, imperatively refer to

“Adjustment of the thermostatic valve (option) and adjustment of the

temperature class”.

In the table below, you will find the possible alternative of temperature

classes depending of the cooling system and the maximal motor

frequency:

Cooling sys-

tem

Direct cooling

Recirculating cooling

Type

Temperature

class

Max. motor

frequency

Temperature

class

Max. motor

frequency

NC 0300 B

T4(i/o)

T3(i/o)

50 Hz

50 Hz

T3(i/o)

50 Hz

T3(i/o)

60 Hz

Installation

Vacuum system

The vacuum system must be placed in a horizontal position on a level

surface.

Make sure there is enough space around the pump system (at least

1.5 m) for service work, etc.

The pipes must be cleaned before assembly. Be sure to completely re-

move any foreign matters such as welding slag and swarf. Flush or

blow out the pipes before connecting up.

Install the inlet pipe (into the nominal diameter of the pump flange or

the inlet valve port) as short as possible because of resistance in the pi-

peline. If longer pipelines (> 5 m) are planned, a wider nominal diame-

ter is necessary.

Connect the pipes in such a way so that no tensile or compressive

stress is placed on the system, using bellows if necessary.

WARNING

A filter or a screen has to be installed on the suction side of the va-

cuum pump, in order to avoid any suction of particles and foreign

matter in the vacuum pump (explosion danger ! ).

The filter or the screen should have a mesh size

£

0.8mm.

Busch offers an intermediate flange screen, which corresponds to this

prescription (for DN50 flange: Busch Part No. 0534 538 534)

The inlet and outlet pipes must be laid with gradients so that no

condensation can enter the pump.

Electrical connection/ Checks

Electrical installation may only be carried out by a specialist.

l

Make sure that the requirements according to EMC-Directive

2014/30/EU as well as the current EN-standards, electrical and

occupational safety directives and the local or national regulations

respectively, are complied with (this is the responsibility of the

designer of the machinery into which the vacuum pump is to be

incorporated; see also the corresponding comments in the

E

U-

Declaration of Conformity).

l

Make sure that the power supply is compatible with the data on

the nameplate of the drive motor

l

Make sure that an overload protection according to EN 60204-1 is

provided for the drive motor

l

Make sure that the drive of the vacuum pump will not be affected

by electric or electromagnetic interference; if unsure please seek

advice from your Busch representative

If the direction of rotation of the pump is wrong, serious damage may

occur.

In order to change the direction of rotation, two phases on the motor

must be reversed.

If the vacuum pump is delivered without drive motor, a drive motor

must be mounted according to the following specifications:

Motor type

3ph motor - synchronous motor

Number of poles

2

Size

COBRA NC 0100 B

BG 100

Size

COBRA NC 0200 B

BG 132

Size

COBRA NC 0300 B

BG 132

BG 160 with adapter flange

Fixing type

Flange, IM 3001 (IM B5)

Assembly position

Shaft horizontal

Network frequency

max. 50 Hz, resp. 60 Hz. See nameplate of the

vacuum pump

Varaible speed drive

Authorized for all vacuum pumps.

The motor must be of nominal constant power

over the entire speed range.

Network voltage

Customised

Protection type

Customised

Explosion protection

In regard to its explosion protection, the motor

must have at least the same protection level as

the vacuum pump for the outside area (“outside”

(o)). See nameplate of the vacuum pump. A

higher protection level, e.g. for the explosion

group or the temperature class, can also be used.

The highest permissible motor power is regulated according to the

operating frequency and the operational mode, see table below:

Installation

Seite/ Page/ Page 16

2G

or

3G

IIB

T3, T4*

No ATEX Zone

2G

or

3G

IIB

2G

or

3G

IIC

or

IIB

II

I

nside

O

utside

II

I

nside

Ex

h

Ex

h

Ex

h

T3,

T4*

T3, T4*

Gb

or

Gc

Gb

or

Gc

X

X

or

Gc

X

O

utside

II

II

Gb