5

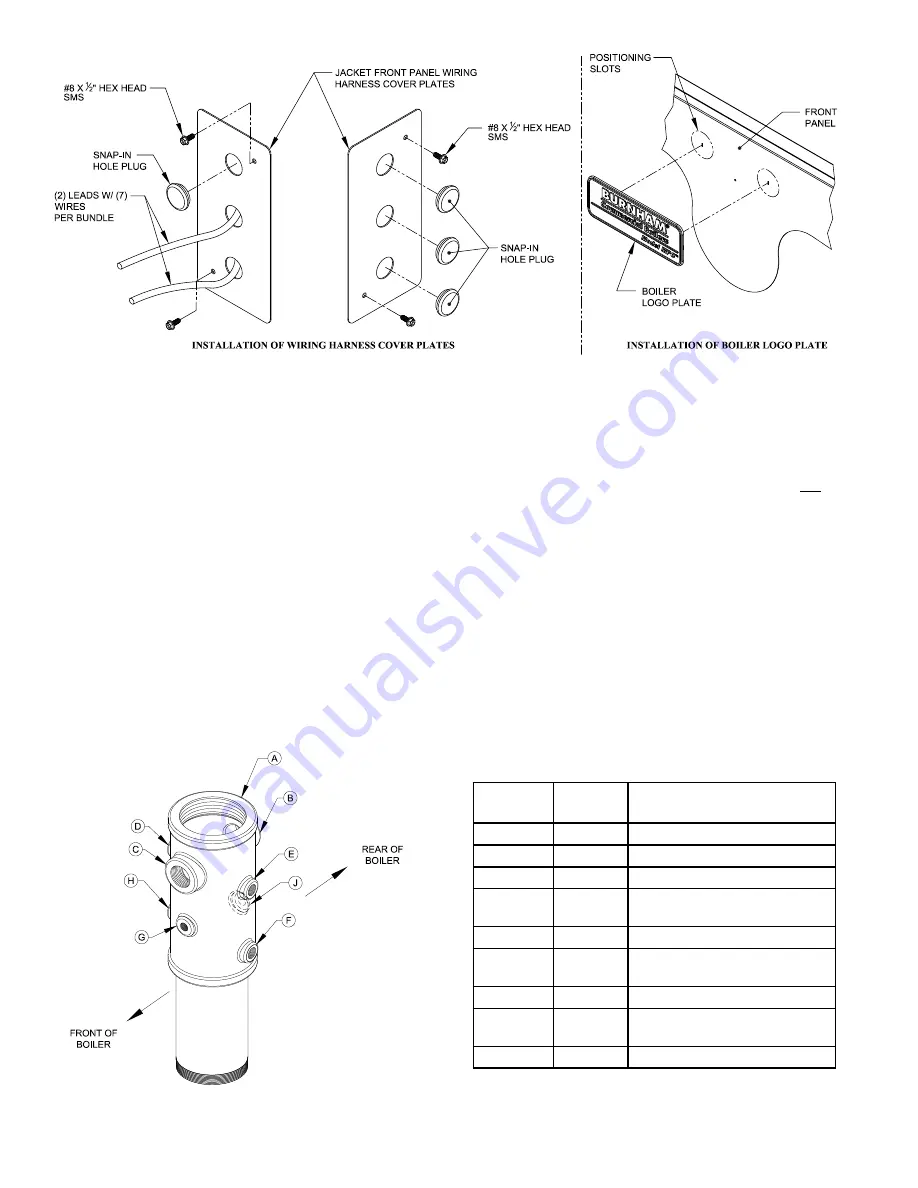

1. Harness is split into two (2) 7 wire bundles that exit

side of front panel as shown in Figure 25.

2. Each seven (7) wire harness bundle must be encased

in flexible conduit from cover plate to burner control

panel or junction box.

3. Locate front panel cover plates in JC-1 carton.

4. Determine routing, length and type of ‘BX’

connectors to be used on flexible conduit.

5. Mount ‘BX’ connector and flexible conduit to

one (1) front panel cover plate. Pull wire bundles

through conduit.

6. Secure cover plate to side of jacket front panel using

(2) #8 x 1/2” lg. hex head SMS.

7. Locate and install one (1) plastic hole plug

(provided) into unused 7/8” dia. hole in cover plate.

8. Install remaining cover on opposite side of front

panel. Secure with #8 x 1/2” lg. hex head SMS,

push (3) plastic hole plugs into 7/8” dia. holes.

Figure 7: Install Jacket Front Panel Harness Cover Plates and Logo Plate

9. Connect other end of flexible conduit to burner

control panel or junction box. Connect control/

safety circuit wires to appropriate terminals per

wiring diagram provided with burner.

Q.

Install Logo Plate on Jacket Front Panel if Optional

Jacket Split Burner Swing Door Cover Panels are

not

to

be used.

Locate Logo Plate shipped in Instruction Envelope.

Peel paper off adhesive strips and install by inserting

positioning tabs on rear of Logo Plate into slotted

openings located at top of front panel shown in Figure

37.

If optional BSD cover panels are used, Logo Plate will

be installed on the cover as instructed in later steps.

R.

Locate Water Trim and Control Carton marked ‘WT’

and remove contents. Check Equipment Check List for

proper working pressure/relief valve. Install standard

trim and controls as follows:

1. See Figure 38 for purpose of tappings on supply

manifold.

Figure 8: Purpose of Tappings in Supply Manifold

*

Location

Size of

Tapping

Purpose of Tapping

A

4” Flange

Supply

B

1½”

Relief Valve

C

1½”

Auxiliary Tapping (Plug)

D

¾”

Operating Temperature

Limit Control

E

¾”

Probe L.W.C.O.

F

¾”

High Temperature Limit Control /

Manual Reset

G

½”

Temperature / Pressure Gauge

H

¾”

Low / High / Low

or Modulating Control

J

½

Low Fire Hold Control

*

Supply Manifold must be installed with 1½” coupling ‘B’

or ‘C’ aligned with front of boiler when water tight.

Summary of Contents for MPC

Page 19: ...19 Figure 5 Manual or Hydraulic Draw up Section Assembly ...

Page 28: ...28 Table VII Modular Return Water Mixing Tube RWMT RC ...

Page 29: ...29 Figure 13 Return Water Mixing Tube RC Assembly and Installation ...

Page 78: ...78 Figure 56 MPC Common Bare Boiler Components ...

Page 80: ...80 Figure 56 MPC Common Bare Boiler Components continued ...

Page 82: ...82 Figure 57 MPC Front Center Section Frame Rail Assembly ...

Page 84: ...84 Figure 58 MPC Rear Section Frame Rail Assembly ...

Page 86: ...86 Figure 59 MPC Return Water Mixing Tube RC Assembly ...

Page 88: ...88 Figure 60 MPC Heat Exchanger Insulation Wrapper ...

Page 90: ...90 Figure 61 MPC Internal Wiring Harness Components ...

Page 92: ...92 Figure 62 MPC Jacket Panel Assembly ...

Page 94: ...94 Figure 62 MPC Jacket Panel Assembly continued ...

Page 96: ...96 Figure 63 MPC 2 nd and 3 rd Pass Flueway Baffles ...