HL-6050/6050D/6050DN SERVICE MANUAL

3-29

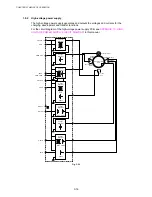

2.6 Print

Process

2.6.1 Charging

The drum is charged to approximately 870V by an ion charge which is generated by the

primary charger. The charge is generated by ionization of the corona wire, which has a DC

bias from the high-voltage power supply applied to it. The flow of the ion charge is controlled

by the grid to ensure it is distributed evenly on the drum surface. The aluminum drum sleeve

in the photosensitive drum is grounded.

+

+

+

+

+

+ + + +

+

+

+

+

+

+

+

+

+ +

+

+

-

-

-

--

-- - - - -

Fig. 3-35

The primary charge uses a corona wire, but since the drum is positively charged, only less

than 1/10 of the usual quantity of ozone is generated compared with the negatively charged

drum. The level of ozone expelled from the printer is therefore not harmful to the human body.

Applicable safety standards have been complied with.

2.6.2 Exposure

stage

After the drum is positively charged, it is exposed to the light emitted from the laser unit.

Fig. 3-36

<Laser exposure unit>

The HL-6050 series printer has a twin laser beam unit to get a resolution of 1200 dpi x 1200

dpi at full-speed printing (A4/LETTER: 24/25 ppm).

1. The two laser beams radiated from a laser diode inside the laser unit are concentrated

into a constant width by a slit in the CO lens cell and then reflected by a polygon mirror

rotating at high speed.

Drum

Lens

Laser beam

Polygon mirror

Paper

Laser detector

Laser diode

Motor

Laser beam

f

θ

lens

Aluminum drum sleeve

Organic photoconductor layer

Photosensitive

drum

Voltage

regulator

870V

Grid

HVPS

Corona wire