CHAPTER 4 DISASSEMBLY AND RE-ASSEMBLY

4-30

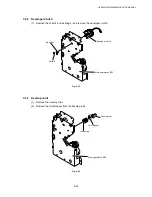

(30) Remove the two open cover springs.

(31) Release the two hooks and two pins, and remove the open cover.

Fig. 4-54

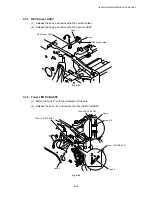

(32) Disconnect the connector of the thermistor C.

(33) Remove the bind M3x4 screw, and remove the fixing sensor PCB ASSY.

Fig. 4-55

Open cover springs

Open cover

Hook

Hook

Pin

Pin

Fixing unit

Thermistor C

Fixing sensor PCB ASSY

Screw, bind M3x4

Fixing unit

1

1

2