38

Section 2 Installation

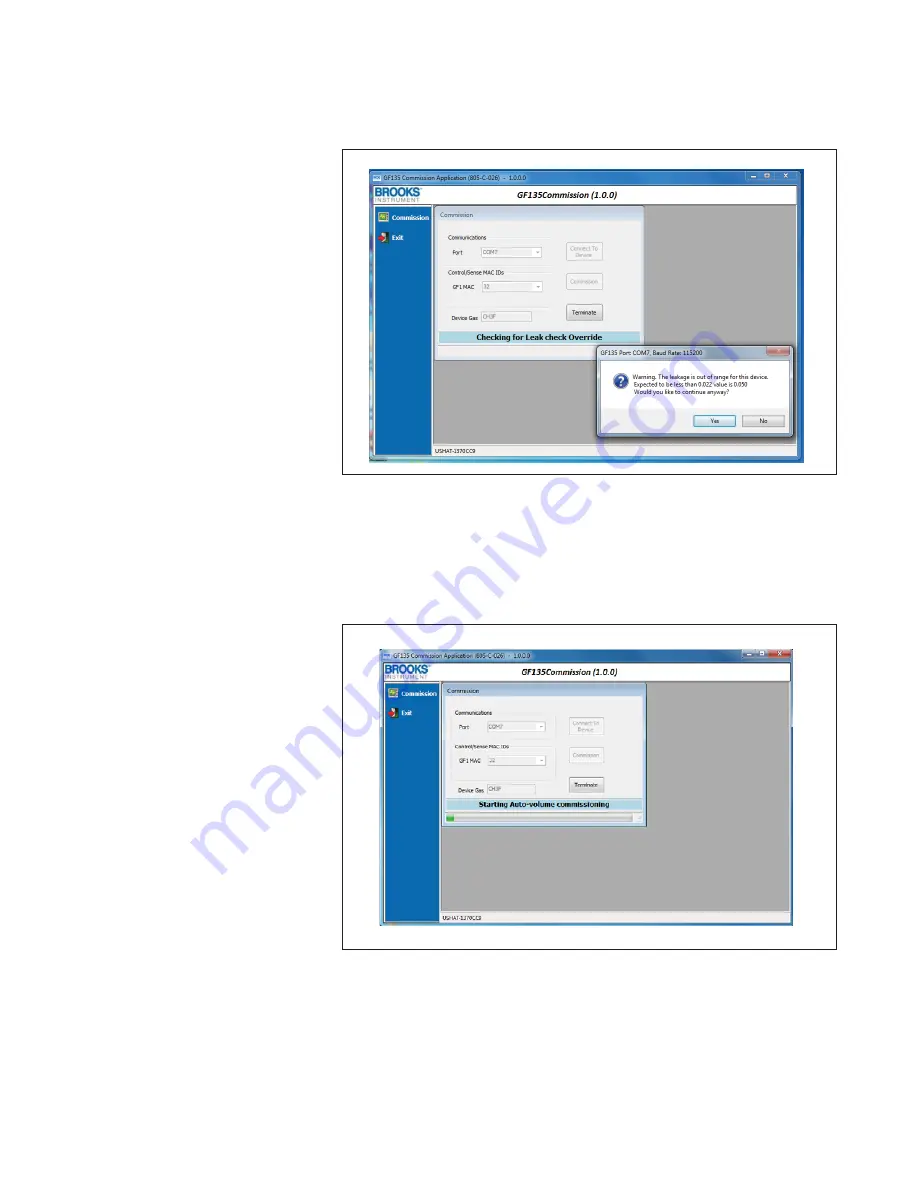

4. The user will be presented the option to override a few of the

parameters being tested prior to actual commissioning. Selecting "Yes" will

continue the process. By selecting "No" the commissioning process will

end.

5. After numerous checks are performed, the auto-volume will start. This

will take approximately 5 minutes to complete. The K1 setpoints will then

begin. This process will run for approximately 40-90 minutes.