8

WINCH AND WIRE ROPE

INSTALLATION

1. The winch should be mounted with the centerline of

the cable drum in a horizontal position. The mounting

plane of the winch may be rotated in any position around

this centerline providing the vent in the motor adapter

is above the centerline of the cable drum. The vent

should be as close to top dead center as possible.

2. When mounting the winch, use all four mounting holes

and Grade 8 bolts and nuts. Evenly tighten the nuts to

the torque in the Recommended Fastener Torque chart.

Make certain the winch drum is centered behind the first

sheave and the fleet angle does not exceed 1-1/2 de

-

grees. The winch should also be mounted perpendicu-

lar to an imaginary line from the center of the drum to

the first sheave to ensure even spooling.

Refer to the dimensional drawing section of this manual

for bolt hole size and pattern.

It is important that the winch is mounted on a surface that

will not flex when the winch is in use, and cause binding of

the gear train. Binding in the gear train will result in accel-

erated wear and heat. Also, the mounting surface should

be flat with +/- 0.020 inch. If necessary, install shims un

-

der the winch mounting pads to achieve even mounting.

3. The hydraulic lines and components that operate the

winch should be of sufficient size to assure minimum

back pressure at the winch. The back pressure at the

motor must not exceed 100 PSI (690 kPa) to maintain

full brake system design factor and optimum motor seal

life.

The winch directional control valve must be a three-posi-

tion four-way valve with a motor spool such that when the

valve is in the center position both work ports are open to

tank (open center, open port).

4. High-quality hydraulic oil is essential for satisfactory

performance and long hydraulic system component life.

Oil having 150 to 330 SUS viscosity at 100°F (38°C) and

viscosity index of 100 or greater will give good results un-

der normal temperature conditions. The use of an oil hav-

ing a high viscosity index will minimize cold start trouble

and reduce the length of warm-up periods. A high vis-

cosity index will minimize changes in viscosity with cor-

responding changes in temperature.

Maximum cold weather start-up viscosity should not ex-

ceed 5,000 SUS with a pour point at least 20°F (11°C)

lower than the minimum ambient temperature.

Under continuous operating conditions the temperature of

the oil at any point in the system must not exceed 180°F

(82°C). 120°F (49°C) to 140°F (60°C) is generally consid-

ered optimum.

In general terms:

For continuous operation at ambient temperatures be-

tween 50°F (10°C) and 110°F (43°C) use SAE 20W; for

continuous operation between 10°F (-12°C) and 90°F

(32°C) use SAE 10W; for applications colder than 10°F

(-12°C), contact the BRADEN/GEARMATIC Service De-

partment. The use of multiviscosity oils is generally not

recommended.

For winch gear oil, refer to lubricant specifications in the

Preventive Maintenance and Specifications section.

5. The hydraulic oil filter should have a 10-micron nominal

rating and be full-flow type.

6. The vent plug in the motor adapter must be located as

close to top dead center as possible. If the winch is

mounted on a pivoting surface, the vent plug must re-

main above the centerline of the cable drum to prevent

gear oil leakage.

7. Refer to the dimensional drawing for relationship be-

tween drum rotation and which port is pressurized.

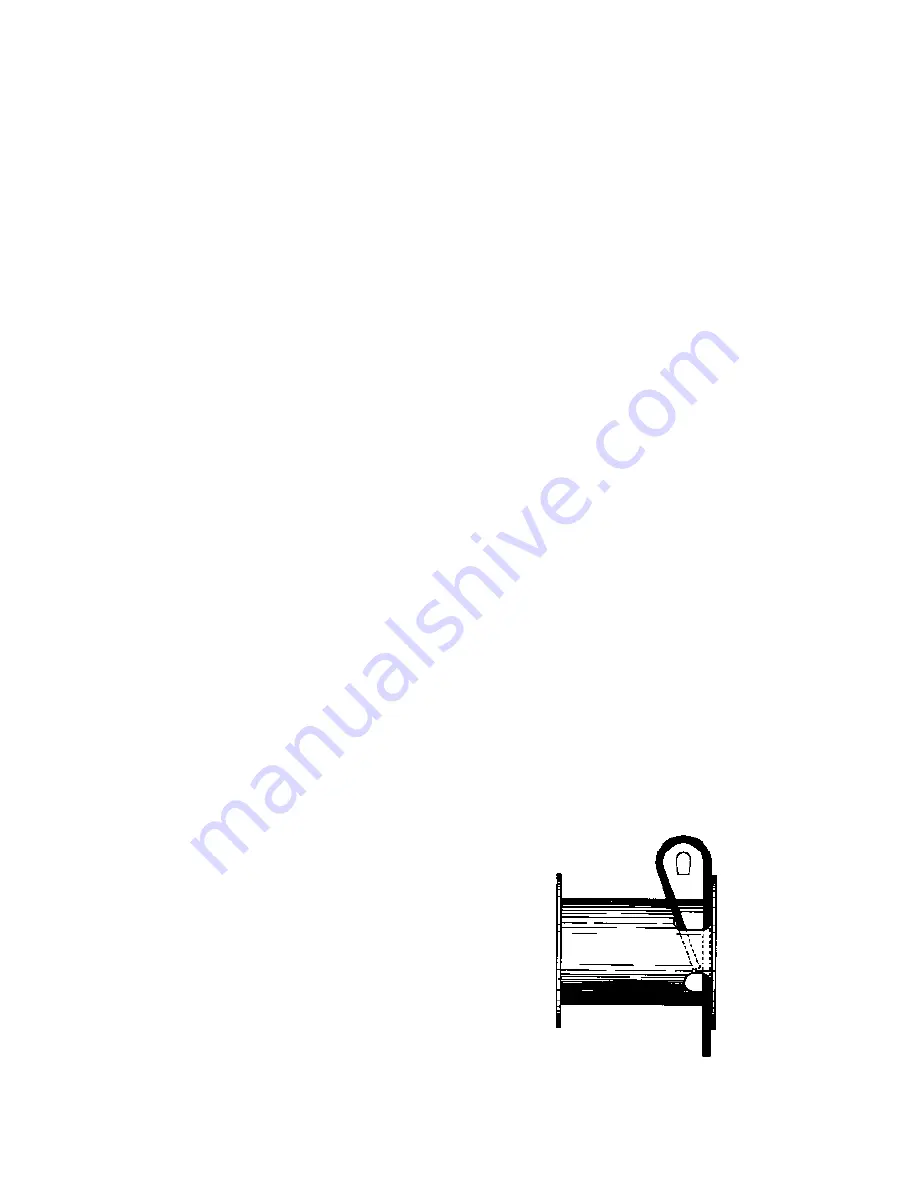

WIRE ROPE INSTALLATION

03 and 04 DRUM

Take the free end of the wire rope and insert it through the

small opening of the anchor pocket you are going to use.

Loop the wire rope and push the free end about three-

fourths of the way back through the pocket. Install the

cable anchor with the small end toward the drum, then pull

the slack out of the wire rope. The cable anchor will slip

into the pocket and secure the wire rope to the drum. A

minimum of five wraps of wire rope should remain on the

cable drum at all times. Refer to General Safety Recom-

mendations section of this manual for additional informa-

tion.

Summary of Contents for CH330

Page 2: ...2...