18

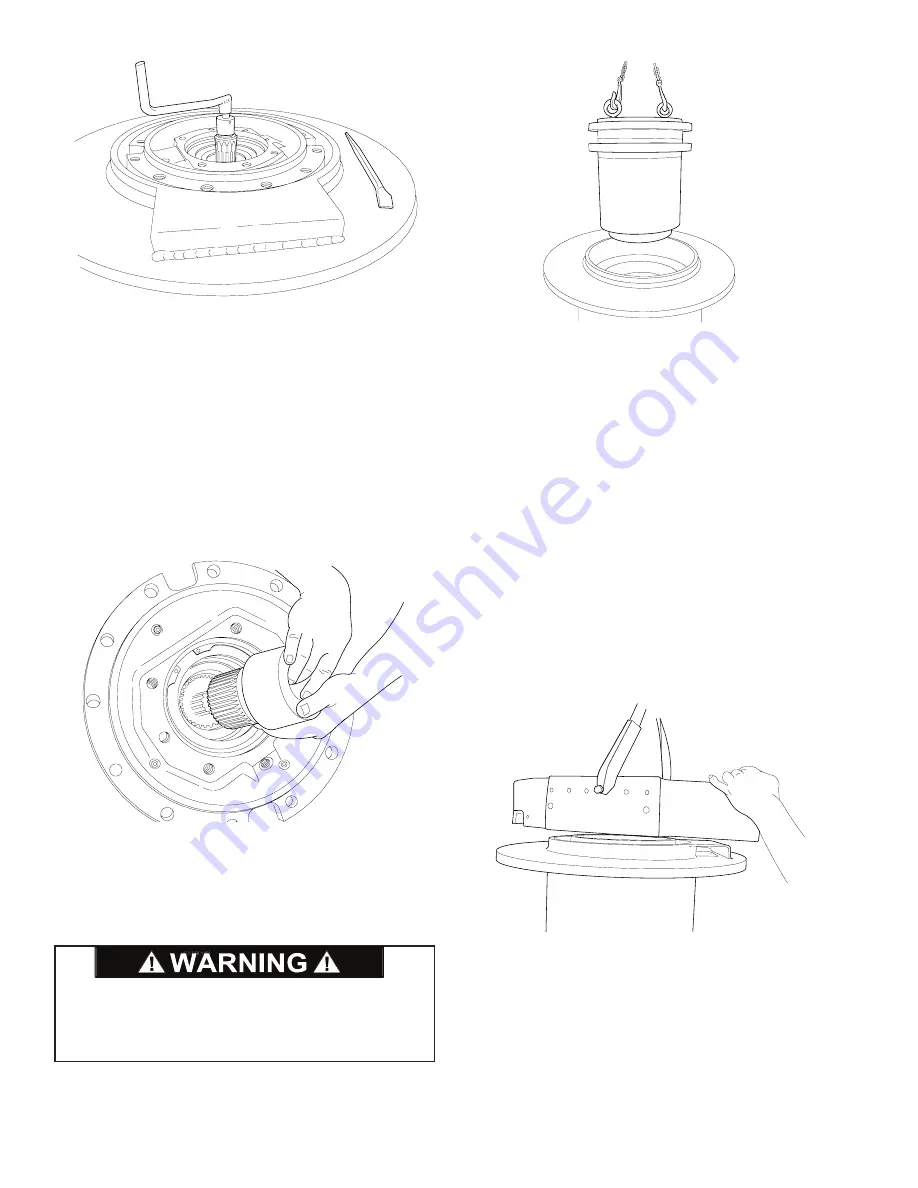

6. There are two large notches in the end of the drive

gearbox. These must be rotated to gain access to the

capscrews and lockwashers (Items 4 and 5) that secure

the gearbox to the winch drum. This is done by rotating

the motor coupling while keeping the drum from turning.

Continue this procedure and remove all capscrews and

lockwashers (Items 4 and 5).

NOTE:

To obtain relative movement between the two

sections of the gearbox, the input shaft must be rotated

in the same direction as the motor turns to haul-in ca-

ble. Rotating the shaft in the opposite direction results

in the entire gearbox and drum turning as a single unit.

7. The brake clutch assembly and motor coupling should

now be removed from the gearbox.

NOTE:

The sun gear will remain in the gearbox and

cannot be removed from this end.

8. Lift the winch drive gearbox out of the drum using two

7/8 NC eyebolts spaced 180 degrees apart as lifting

lugs. Refer to Winch Drive/Gearbox Service section for

further disassembly of winch drive.

DRUM SUPPORT

END BRACKET SERVICE

If the winch disassembly procedure has been followed to

this point, remove the C-clamps installed in step 4. If only

this end of the winch is being serviced, support the winch

on the motor end bracket and remove the 12 capscrews

and lockwashers securing the end of both tie plates (Item

1), to the drum support end bracket (Item 2). Loosen

the 12 capscrews on the other end of both tie plates just

enough to allow the tie plates to be pried free of the dowel

pins in the drum support end bracket.

1. Lift the support end bracket from the drum.

NOTE:

If the winch disassembly procedure was fol-

lowed and the drum is on top of the end bracket, lift the

drum from the support end bracket.

DO NOT attempt to remove the large retaining ring at

this time. It is holding the static brake spring in com-

pression. Removing this retaining ring at this time could

result in property damage, personal injury, or death.

Summary of Contents for CH330

Page 2: ...2...