23

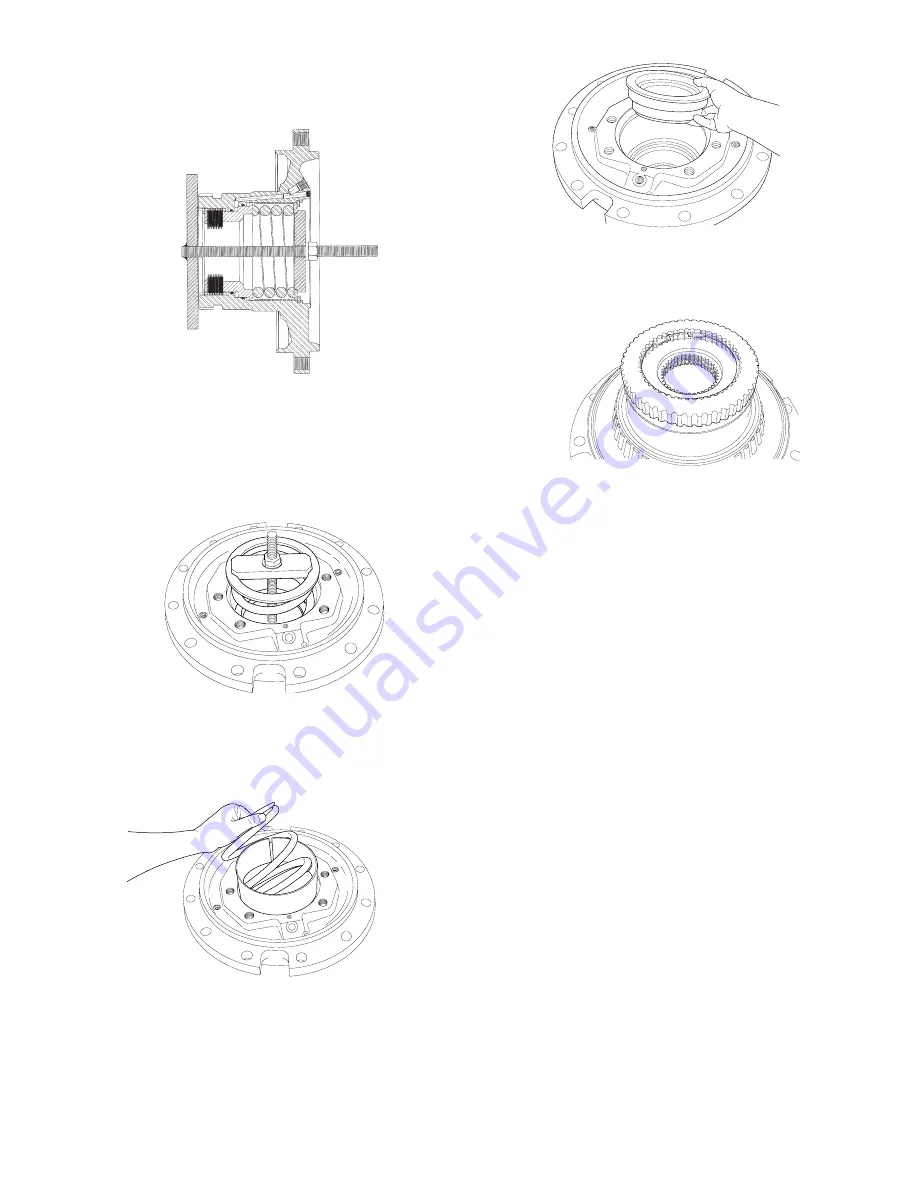

BRAKE ASSEMBLY

DISASSEMBLY

1. Install the spring compressor tool as show. If a hydrau-

lic press is available, only part A of the tool is required.

Tighten the nut above part A or apply hydraulic pressure

to slightly compress the spring and relieve load on the

retaining ring (Item 94). Carefully remove the retaining

ring.

2. Slowly and carefully unscrew the nut above part A until

spring pressure is completely released (spring travel is

approximately 4 inches [10 cm]). Remove the compres-

sor tool.

3. Remove the spring stop (Item 93), spring (Item 91) and

piston stop (Item 92) from the brake cylinder.

4. Remove the brake piston (Item 90). Remove and dis-

card both sets of piston O-rings and backup rings (Items

86, 87, 88, 89).

5. Turn the assembly over to access the brake plates. Re-

move the retaining ring (Item 81). Remove the spacer

plate (Item 82), steel separator discs (Item 83) and fric-

tion discs (Item 84).

Thoroughly clean and inspect all parts, paying close at-

tention to the sealing surfaces of the brake piston. Place

each friction disc on a flat surface and check for distortion

with a straight edge. Friction material should appear even

across the entire surface and the groove pattern should

be visible. Replace friction discs if splines are worn to a

point, disc is distorted, friction material is worn unevenly

or groove pattern is no longer visible. Place each steel

brake plate on a flat surface and check for distortion with a

straight edge. Check surface for signs of material transfer

or heat. Replace steel discs if splines are worn to a point,

disc is distorted or heat discolored.

Check the brake release passage to be sure it is clean and

completely open.

Inspect both sets of large tapered roller bearings (Items

49, 50, 51, 52) for signs of damage or excessive wear.

The bearing rollers should not exhibit any irregularities. If

the rollers show any sign of spalling, corrosion, discolor-

ation, material displacement or abnormal wear, the bear-

ing should be replaced. Likewise, the cage should be in-

spected for wear or deformation. If there is any damage

that would impair the cage’s ability to separate, retain and

guide the rollers properly, the bearing should be replaced.

Summary of Contents for CH330

Page 2: ...2...