25

7. Install the piston stop (Item 92) and the brake spring

(Item 91).

8. Set the spring stop (Item 93) on the spring and install

the spring compressor tool, or move the assembly to

a press. Be sure the step on the compressor tool is

squarely seated on the spring stop.

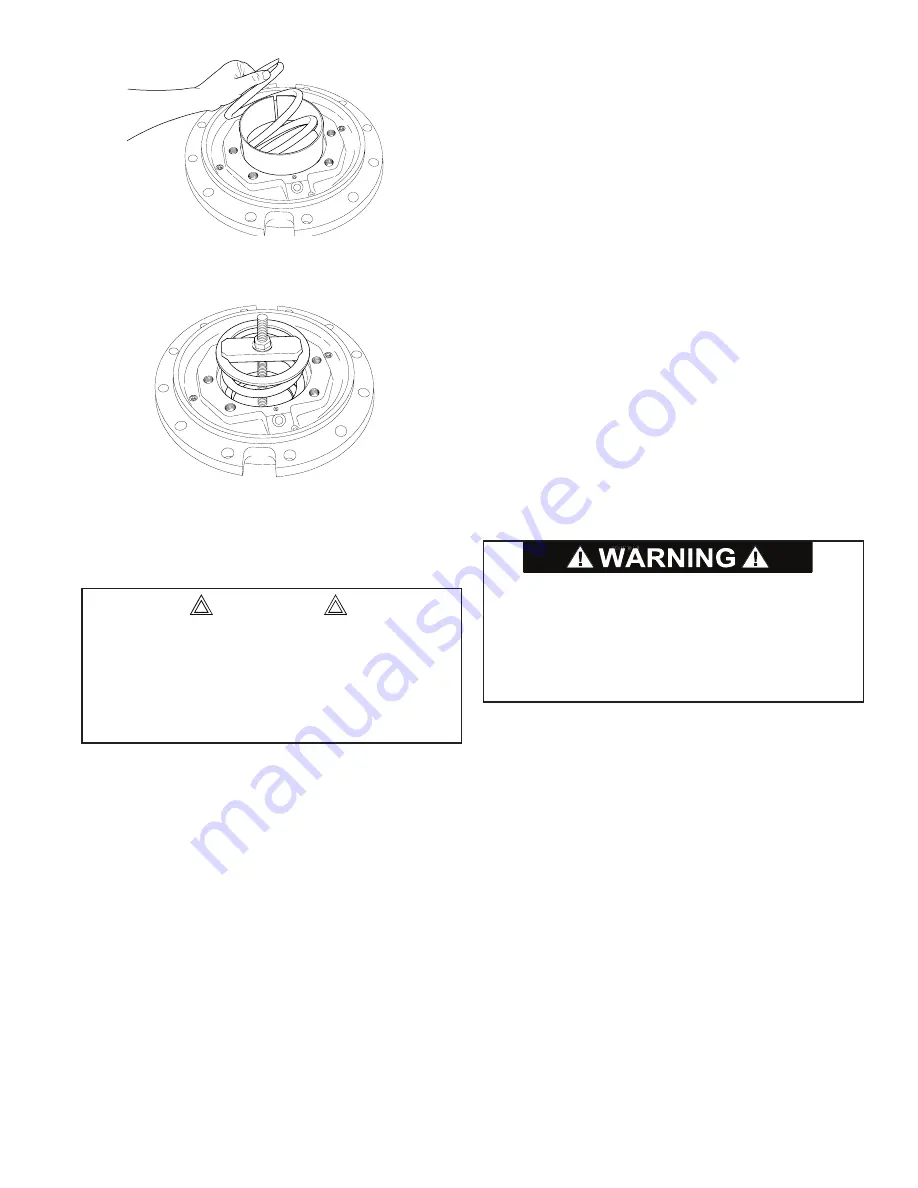

9. Slowly compress the spring until the spring stop is

slightly below the retaining ring groove in the motor sup-

port. Install the retaining ring (Item 94).

NOTE:

The holes in the ends of the retaining ring are

slightly tapered. The smaller end of the hole

MUST

be installed away from the spring stop, or toward the

motor, to prevent the ring from slipping off the pliers

when installed or removed. Be sure the retaining ring is

completely seated in its groove, and slowly release the

spring compressor until the force of the spring is held by

the retaining ring. Remove the spring compressor tool.

Brake Cylinder Pressure Test

1. Connect a hydraulic hand pump with an accurate gauge

and shut-off valve to the brake release port of the motor

support. Apply 500 PSI (3,450 kPa) to the brake. Close

the shut-off valve and let stand for five minutes. If there

is any loss of pressure, the brake cylinder should be

disassembled for inspection of the sealing surfaces and

O-rings.

WHILE PRESSURE IS APPLIED AND THE BRAKE IS

RELEASED, install the sprag clutch assembly. Rotate the

clutch back and forth to align the splines in all brake discs.

When the sprag clutch has engaged all the discs, release

the pressure on the brake cylinder and remove the sprag

clutch.

Sprag Clutch Assembly

Before disassembling the sprag clutch, make note of the

freewheeling direction of the inner brake race (Item 102).

Hold the outer race (Item 96) and try to turn the inner race

in both directions. It should turn free of the outer race

in one direction only. If the inner race will not turn freely

in either direction, or turns freely in both directions, the

sprag clutch assembly has been damaged and must be

replaced.

1. Remove the retaining ring (Item 104). All other internal

parts can now be removed, including the sprag assem-

bly (Item 99) and the roller bearing (Item 97).

2. Thoroughly clean all parts in solvent and inspect for

signs of wear and/or damage. Inspect the sprag clutch

and roller bearing closely for abnormal wear, cracks,

pitting or corrosion. Check small clips for breakage or

bright spots; the signs of excessive wear.

3. Apply a light coat of gear box lubricant to all components

as they are assembled. Install the roller bearing (Item

97) into the outer race (Item 96). Install spacer (Item

98) on top of roller bearing. Install the sprag clutch as-

sembly (Item 99).

NOTE:

The sprag assembly con-

sists of three parts; two U-shaped bronze spacers and

a cam assembly. The bronze spacers are installed with

their open end toward the cam assembly, one spacer

on each side. Rotate the cam assembly while gently

pressing it into the outer race.

Before installing the inner race (Item 102), be sure the

internal retaining ring (Item 101) is installed and fully seat-

ed. Slide the inner race through the sprag clutch (the race

will have to be rotated in the freewheeling direction to start

it into the clutch). Be sure the inner race turns freely in

the same direction determined before the unit was disas-

sembled. If it turns freely in the opposite direction, the

sprag clutch has been installed backwards and must be

reversed. Install spacers (Items 100 and 103), and retain-

ing ring (Item 104).

The brake spring must be compressed approximately

4 inches (10 cm) and has a compressed force of ap-

proximately 1,500 lb (680 kg). Extreme care should be

observed while completing this step to avoid sudden

release of the spring.

DO NOT

stand directly in front of

the spring while it is being compressed.

CAUTION

The polished surfaces of the inner and outer races must

be perfectly smooth to ensure positive engagement of

the clutch. The slightest defect may reduce sprag clutch

effectiveness, which could result in property damage,

personal injury, or death. The entire sprag clutch as-

sembly must be replaced if any component is defective.

Summary of Contents for CH330

Page 2: ...2...