28

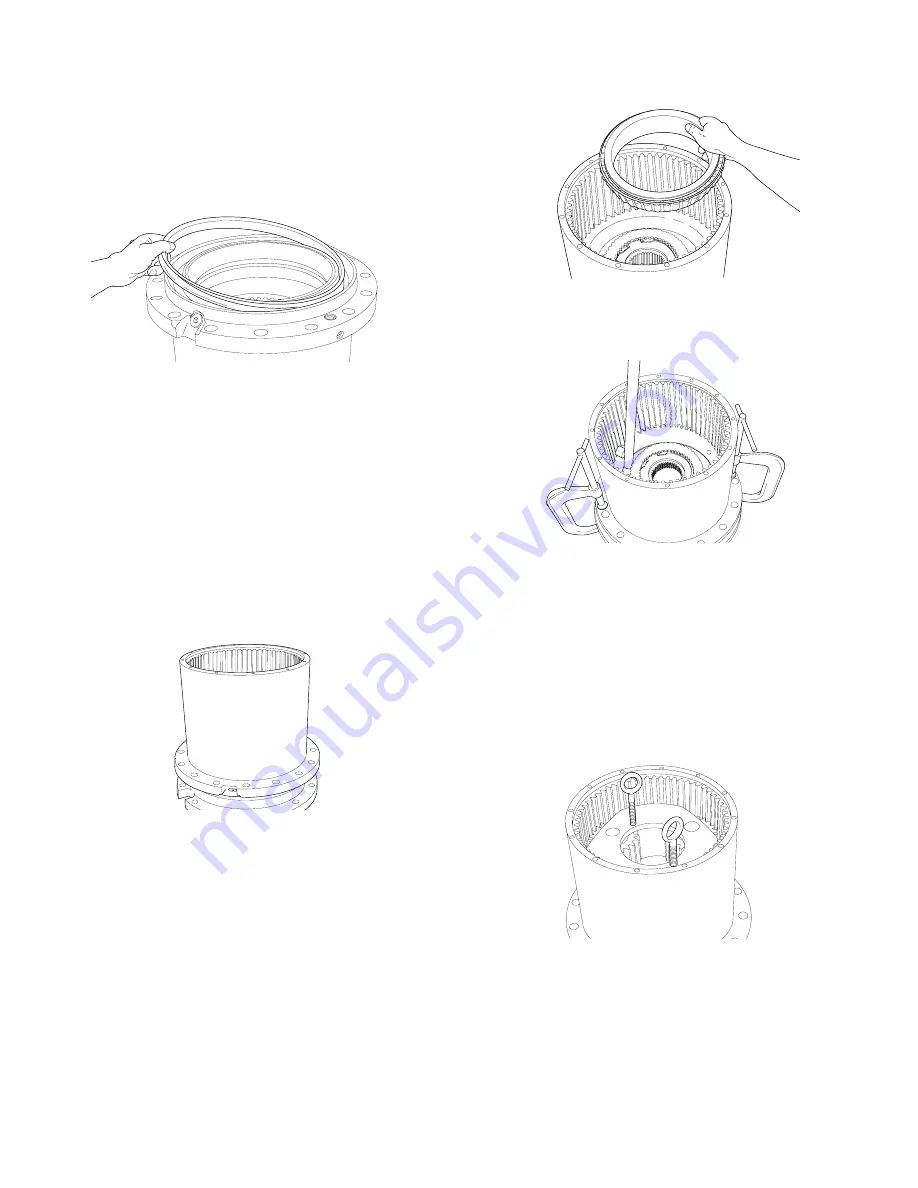

The following procedure should be used to assemble a

complete winch and drive gearbox. It assumes all sub-

assemblies have been properly serviced as described in

previous sections of this manual.

1. If the metal seal (Item 53) is being replaced, install one

half of the seal in the motor support and the other half

in the ring gear. The old seal is simply pried out of its

seat. Clean the seal seat area in both the motor sup-

port and ring gear.

NOTE:

Handle the new seals with care. The metal

contact areas must remain perfectly flat and free of

nicks or dents for the seal to operate leak free.

Apply a liberal coat of oil soluble grease to the new

seal O-rings and install one O-ring on each seal half.

Each seal half can then be gently worked into its seat

in the motor support and ring gear.

2. If the tapered roller bearings (Items 49, 50, 51, 52) are

being replaced, install bearing cone (Item 52) onto the

motor support. Install both bearing cups (Items 50 and

51) into the ring gear. Set the motor support on your

workbench with the motor end down. Apply a light

coat of oil to the mating surfaces of the metal seal, and

set the ring gear down onto the motor support. Mat-

ing surfaces of the seal should be in contact with each

other and the ring gear should rotate smoothly.

WINCH ASSEMBLY

3. Install the bearing cone (Item 49) onto the motor sup-

port. Use a bar or flat ended punch to fully seat the

bearing. Again check that the ring gear rotates freely.

4. Install two large C-clamps between the flanges of the

motor support and ring gear. Tighten the C-clamps

firmly and again fully seat the bearing installed in step

3. Install both halves of the split ring (Item 48) into the

groove on the motor support. A 1-inch diameter bar

and various sizes of steel blocks or key stock can be

used, if necessary, to force the split ring halves into the

groove. Be careful to avoid damaging the ring gear

teeth while installing the split ring. Remove the two

C-clamps.

5. Install 2 each 1/2–13 eyebolts into the output planet

carrier and use them to set the planet assembly into

the ring gear. Rotate the planet carrier to engage the

splines on the motor support. In addition to engaging

the splines, the planet carrier must drop down over the

split ring halves, holding them in position.

Summary of Contents for CH330

Page 2: ...2...