33

shown above are included in the kit. We recommend that

this kit be installed whenever the brake valve is removed

for inspection or service.

It is always a good practice to check the initial opening or

cracking pressure of the brake valve whenever the hoist is

serviced or inspected. Refer to BRADEN Service Bulletin

number 527 for complete brake valve test and adjustment

procedures.

DISASSEMBLY

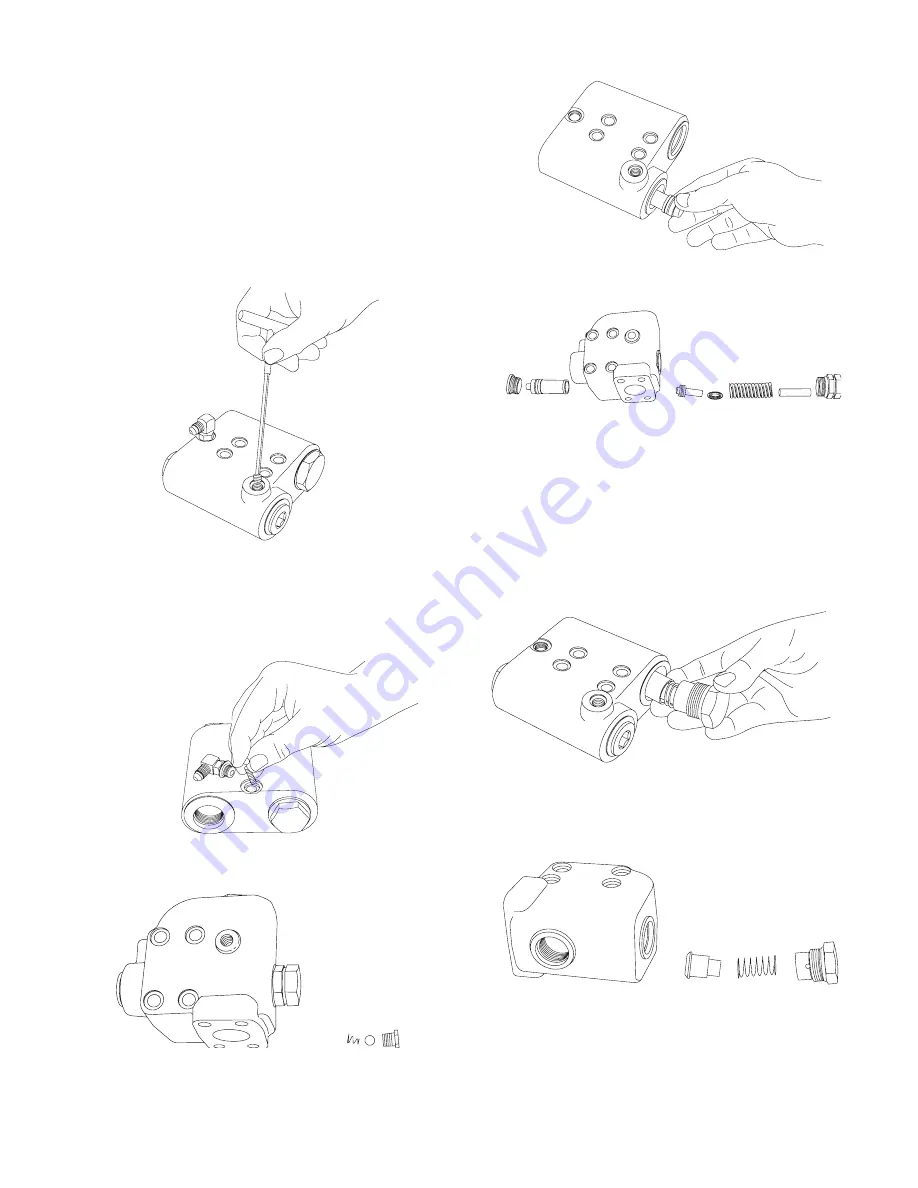

1. On the 1-1/4-inch valve only, remove the pilot orifice

from the brake release port using a 5/32-inch Allen wrench.

1-1/4-inch Valve

1-1/2-inch Valve

2. Remove the fitting, motor drain check ball and spring.

1-1/4-inch Valve

1-1/2-inch Valve

3. Remove the spool spring retainer and spool spring.

Remove the spool plug and carefully remove the spool

assembly. Remove the damper piston from the spool.

The piston will come out of the spool slowly, because of

a partial vacuum formed between the two. Use extreme

care to avoid damaging the polished surfaces of either

piece.

1-1/4-inch Valve

1-1/2-inch Valve

4. Remove the check valve spring retainer, spring and

check valve poppet.

CLEAN AND INSPECT

1. Discard all O-rings and backup rings. Clean all parts

in solvent and blow dry. Inspect polished surfaces of

spool and damper piston for damage that may cause

Summary of Contents for CH330

Page 2: ...2...